PRODUCT

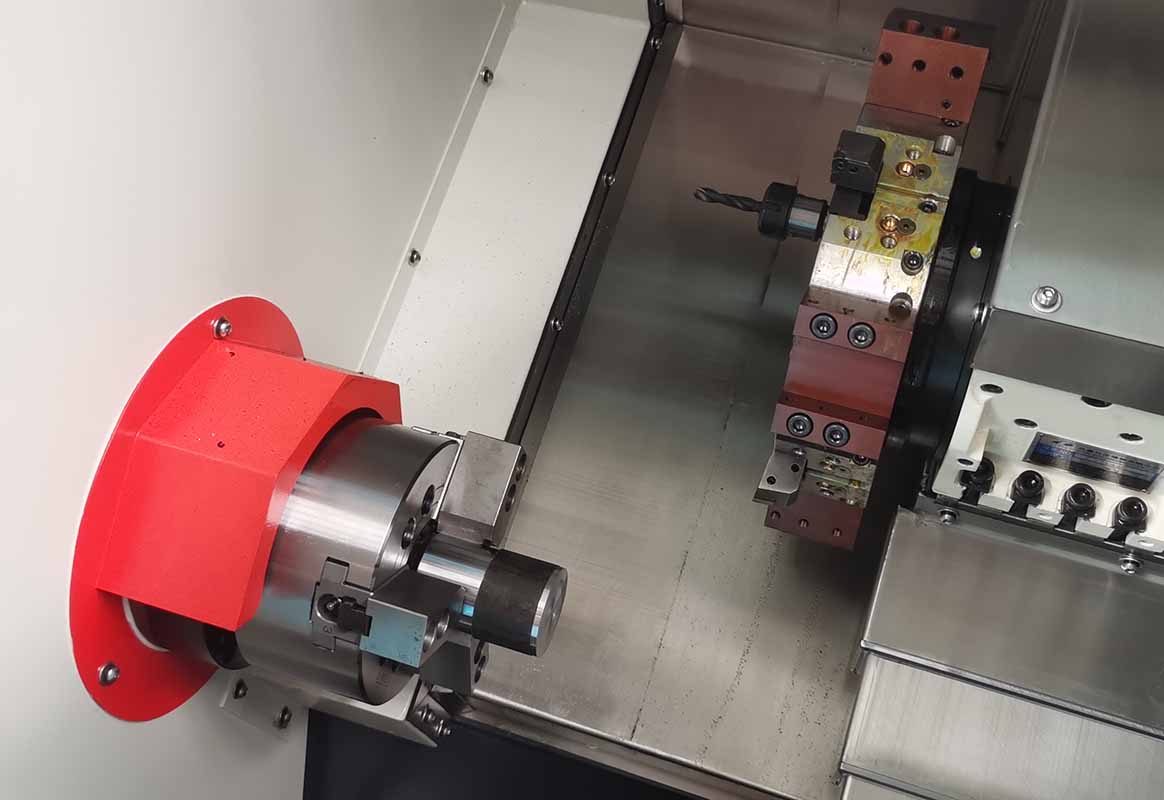

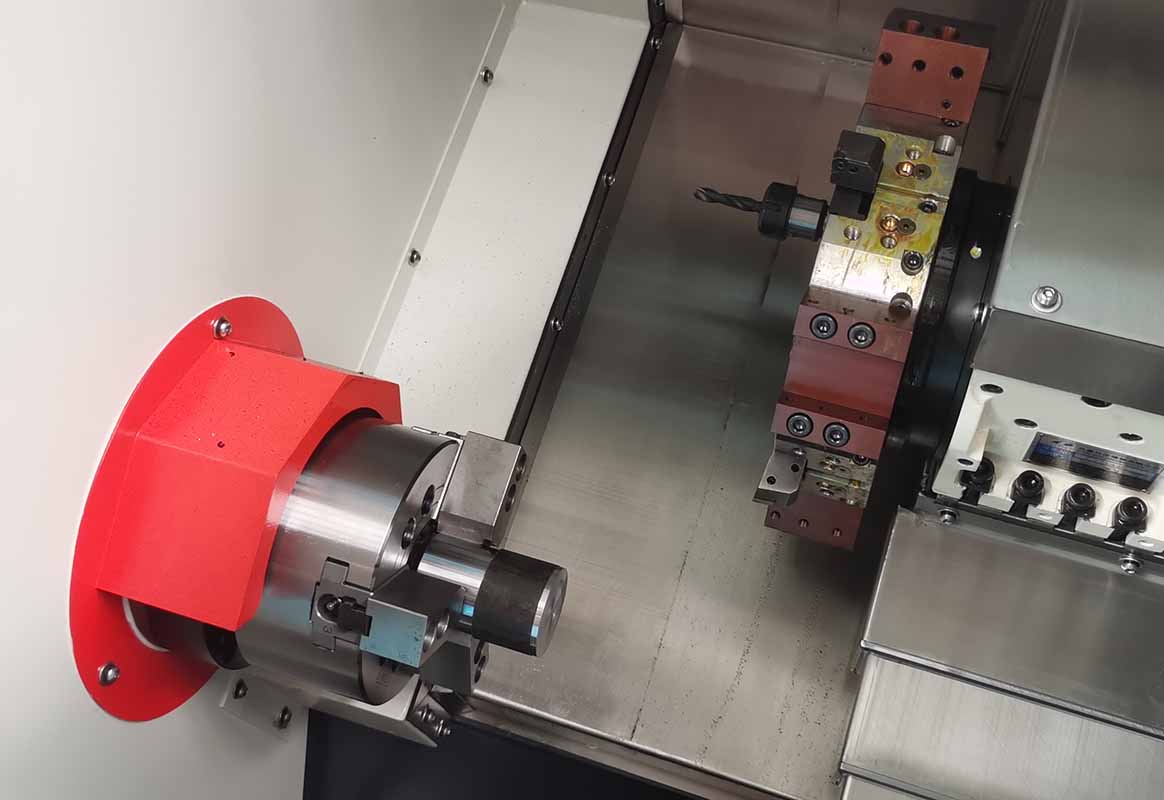

Slant Bed CNC Lathe TCK46A

TCK46 Slant Bed CNC Lathe is a high-efficiency, high-precision metal processing equipment with a slanted bed design, high-precision ball screw + linear rail/hard rail, and a cast iron bed with various optional configurations. It can be equipped with an automatic feeder, tailstock, power turret, servo turret, etc.

TCK46 Slant Bed CNC Lathe has more stable cutting, smooth chip removal, prevents iron chips from accumulating, is more ergonomic and easier to operate.

The spindle uses high-precision bearings, runs smoothly, and is suitable for high-speed cutting. Automatic lubrication system prolongs machine tool life and reduces maintenance costs

Product Features

TCK46 Slant Bed CNC Lathe High machining accuracy: high repeatability, suitable for mass production

Strong cutting ability: can withstand large cutting volume, high efficiency

Space saving: compact structure, small footprint

Simple operation: programming, user-friendly interface, easy to use

Adapt to automated production line: convenient for docking with manipulator or truss robot arm

Product application industry

TCK46 Slant Bed CNC Lathe In the automotive industry, the main processing parts are: wheel hubs, shafts, brake discs, drive shafts, pistons, spare parts and accessories

In aerospace, the main processing parts are: turbine shafts, connectors, aviation fasteners, and housing parts

In medical devices, the main processing parts are: orthopedic implants, medical device accessories, and small precision shafts

In hardware machinery, the main processing parts are: plumbing accessories, nuts, flanges, connectors, and small precision parts

In electronic communications, the main processing parts are: communication connectors, mobile phone parts, and electronic screws

In mold manufacturing, the main processing parts are: mold accessories, inserts, ejectors, etc.

Video

Product Parameter

| Item | Unit | TCK46A |

| Max. swing dia. over bed | mm | Φ460 |

| Max. swing dia. over slide | mm | Φ260 |

| Max. processing length | mm | 350 |

| Spindle speed | rpm | 3500 |

| Spindle hole diameter | mm | 56 |

| Weight | KG | 3000 |

| Machine size | mm | 2500×1700×1890 |