PRODUCT

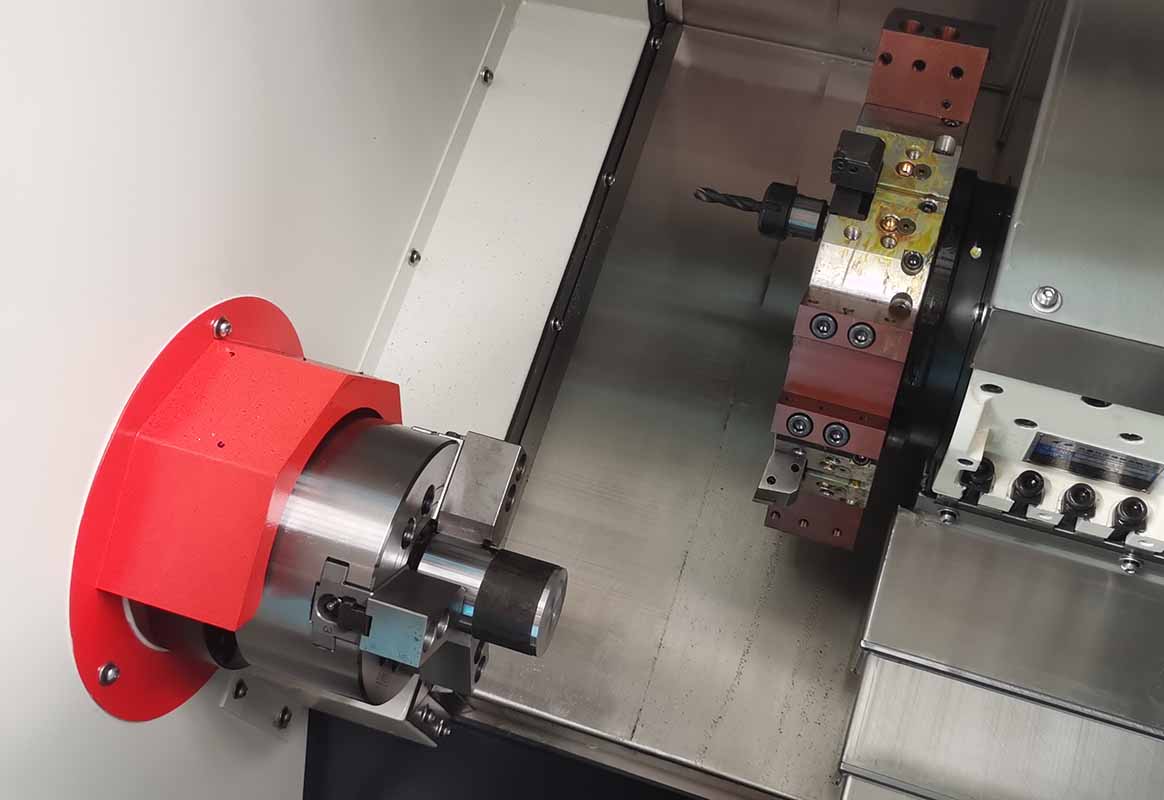

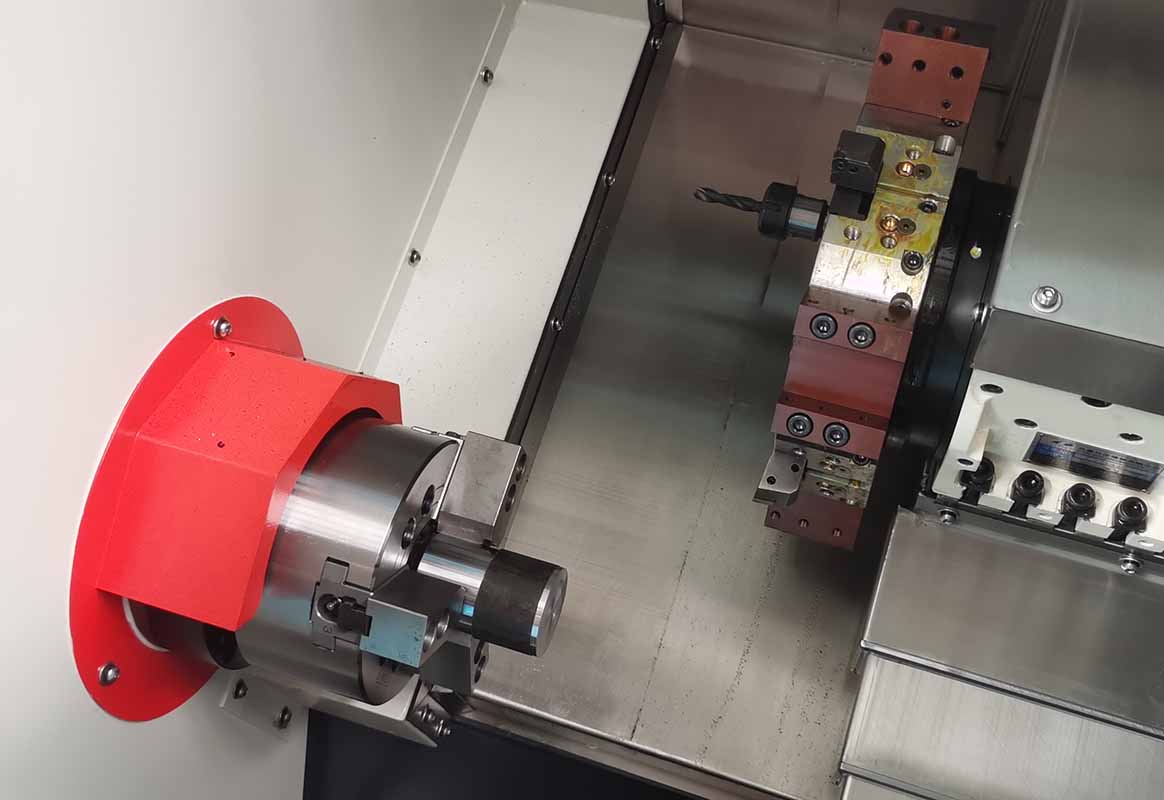

TCK46A Slant Bed CNC Lathe

The slant bed design usually has higher structural rigidity, which helps to improve the stability and accuracy of machining. The slant bed layout reduces the vibration of the workpiece and tool during machining, thereby improving the machining quality.

The layout of the slant bed lathe is usually more compact, saving floor space.

It can also be designed with a tool holder and tailstock with a larger stroke, which is suitable for processing larger and more complex workpieces.

Product Features

1.TCK46A inclined bed design usually has higher structural rigidity, which helps to improve the stability and precision of machining. The inclined bed layout reduces the vibration of the workpiece and tool during machining, thereby improving the machining quality.

2.TCK46A inclined bed design allows chips to slide naturally by gravity, making chip removal smoother, reducing the interference of chip accumulation on the machining process, and improving work efficiency and machining safety.

3.TCK46A inclined bed design makes the operator's working position more comfortable and easy to observe and operate. The inclined bed usually has a lower workbench height than the flat bed, making it easier for operators to perform clamping and measurement operations.

Product application industry

Metal cnc lathe machine is a full-featured precision CNC lathe with high precision, flexibility and durability, large and practical appearance, and various advantages of cutting tools and walking machines.

Metal slant bed cnc machine is suitable for precision machining of various high-precision, multi-batch, complex-shaped parts in aviation, electronics, clocks and other industries.

Video

Product Parameter

| Item | Unit | TCK46A |

| Max. swing dia. over bed | mm | Φ460 |

| Max. swing dia. over slide | mm | Φ260 |

| Max. processing length | mm | 350 |

| Spindle speed | rpm | 3500 |

| Spindle hole diameter | mm | 56 |

| Weight | KG | 3000 |

| Machine size | mm | 2500×1700×1890 |