PRODUCT

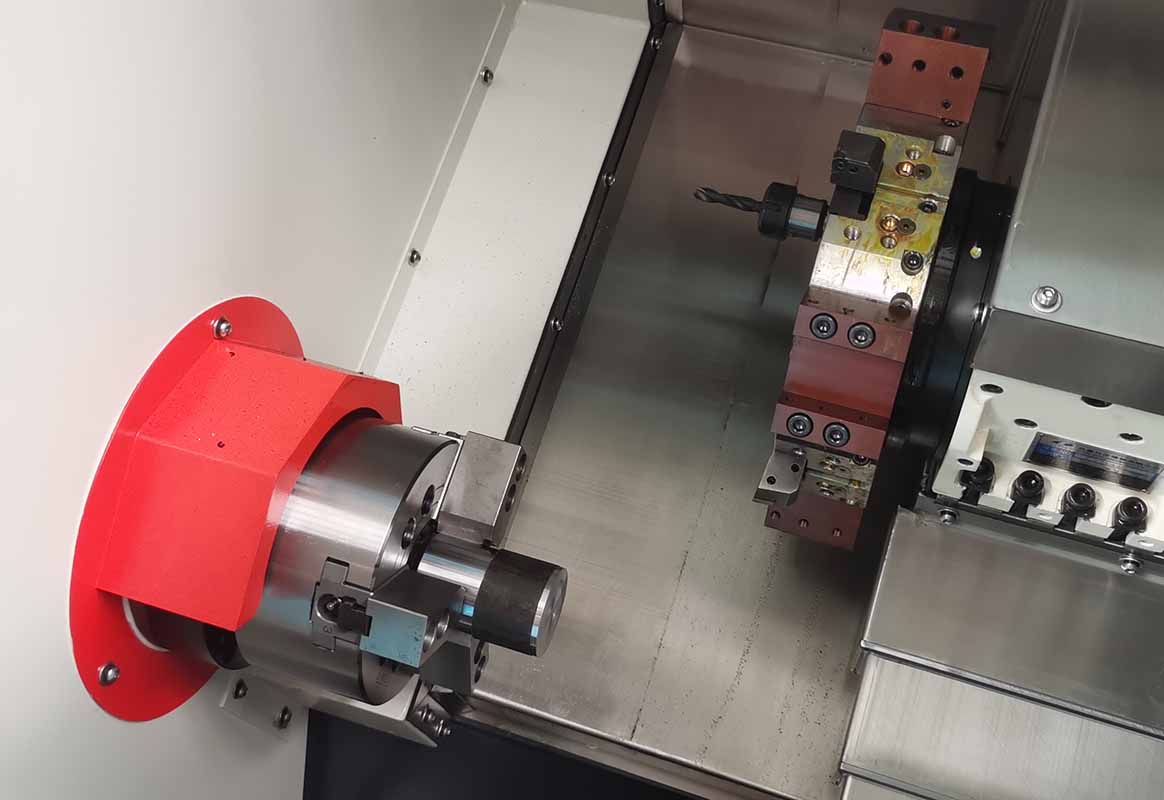

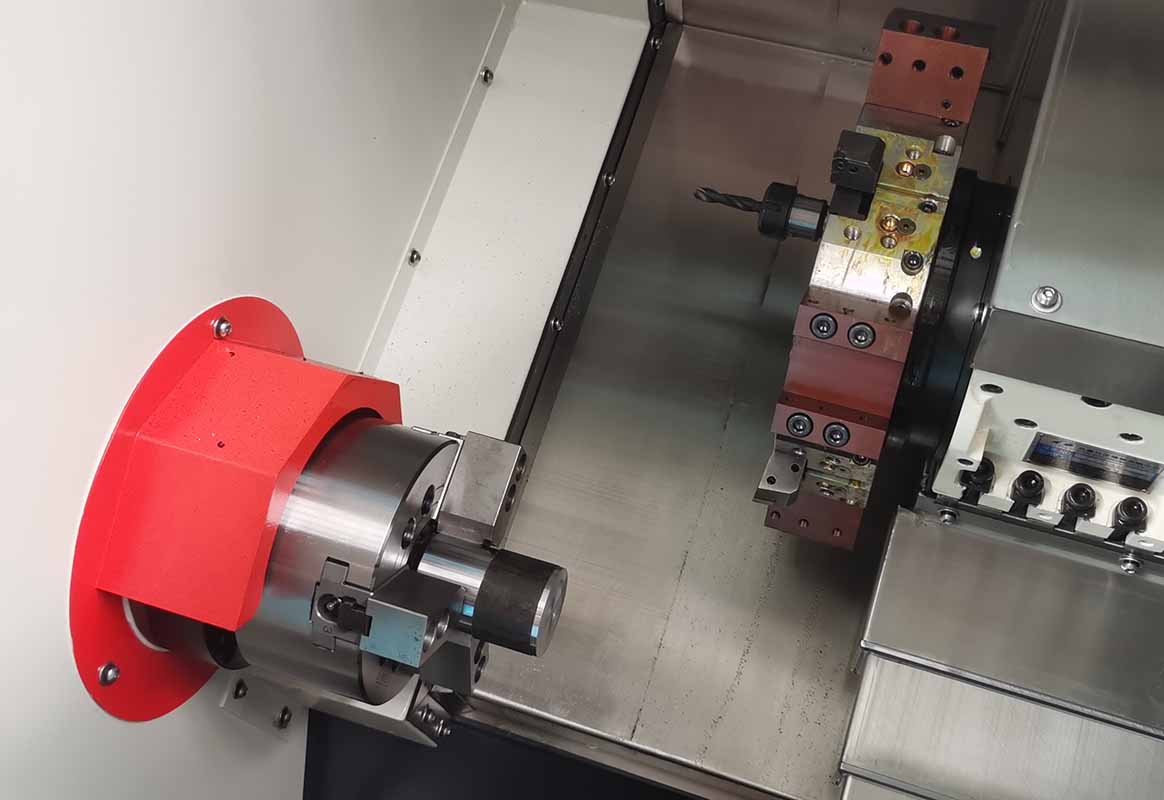

TCK36A Slant Bed CNC Lathe

TCK36A Slant Bed CNC Lathe (36°/45° tilt design) improves chip removal efficiency, makes operation more convenient, facilitates loading and unloading of workpieces, and reduces operator fatigue.

High-rigidity integrated bed, the bed is made of high-strength cast iron, and has undergone secondary aging treatment to ensure that it will not deform during long-term processing.

High-precision spindle unit, the spindle adopts high-precision rolling bearings, with high rotation accuracy, suitable for high-speed and efficient processing.

Multi-axis linkage control (optional), can expand the Y-axis and C-axis to achieve turning and milling compound processing.

TCK36A Slant Bed CNC Lathe Servo turret/hydraulic turret, fast tool change, accurate positioning, reducing non-cutting time.

Fully enclosed protection design ensures safe operation, prevents chips from splashing, and keeps the processing environment clean.

Automatic lubrication system realizes automatic lubrication of each moving part and extends the life of the machine tool.

Advantage

TCK36A Slant Bed CNC Lathe High-efficiency machining, the inclined bed structure makes machining and chip removal smoother, suitable for long-term automatic operation.

Small footprint, compact layout, suitable for batch production of small to medium-sized workpieces, saving plant space.

High-precision stability. Suitable for high-precision machining scenarios, such as turning of complex surfaces.

High degree of automation, can be matched with automatic loading and unloading system to form an unmanned production line.

Simple maintenance, easy operation, humanized design, reducing operator training time.

Product application industry

TCK36A Slant Bed CNC Lathe is particularly suitable for batch turning of small to medium-sized rotating parts in the automotive industry, such as hub centers, bushings, flanges, steering components, etc. It is an indispensable CNC turning equipment in the automotive parts processing production line.

Application in the medical device industry: Main processing workpieces; 1. Orthopedic implants 2. Surgical instrument accessories 3. Medical tubes and joints 4. Medical equipment parts

Application in the hardware machinery industry: Main processing workpieces; 1. Standard parts & fasteners 2. Engineering machinery parts 2. Engineering machinery parts 2. Engineering machinery parts

Video

Product Parameter

| Item | Unit | TCK36A |

| Maximum upper turning diameter of bed | mm | Φ360 |

| Maximum machining diameter on tool post | mm | Φ140 |

| Maximum processing length | mm | 300 |

| Spindle speed | rpm | 4000 |

| Spindle hole diameter | mm | 48 |

| Weight | KG | 2200 |

| Machine size | mm | 2200×1600×1850 |