PRODUCT

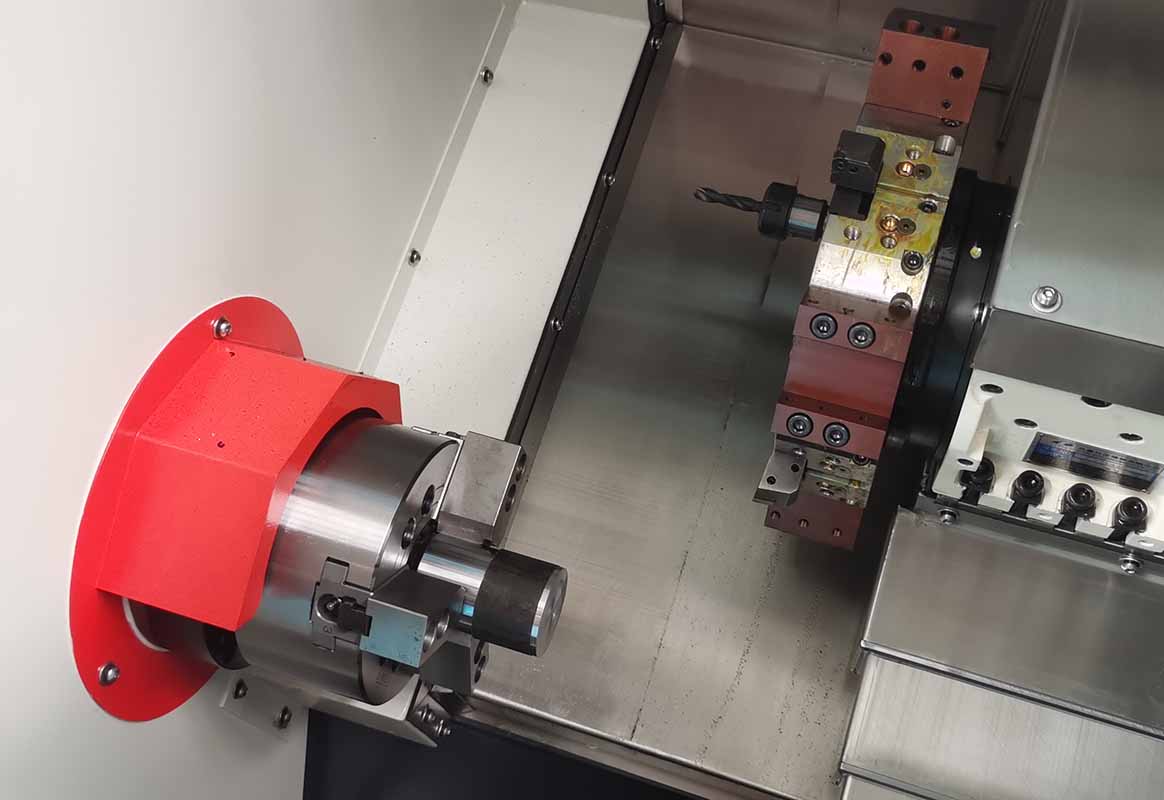

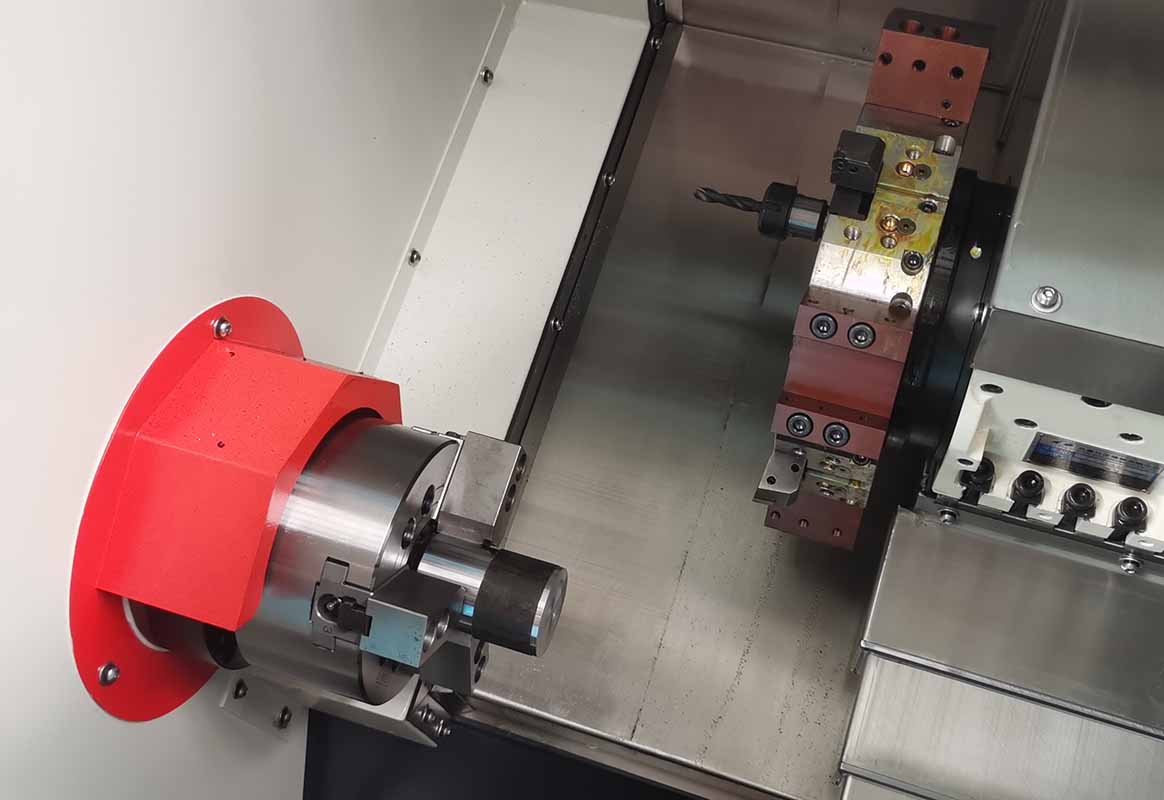

Slant Bed CNC Turning Center TCK36A

The inclined bed CNC lathe has high-efficiency and high-precision automatic processing. It adopts a 45-degree high-rigidity integral bed, high-precision spindle unit, and Taiwan line rails to ensure high rigidity of the whole machine. The center of the spindle is close to the operator, and it is more convenient to load and unload workpieces.

When processing Slant bed CNC lathe, a part can have several different processes. I can improve production efficiency and reduce production costs according to the specific conditions of production, and formulate a reasonable processing process.

Advantage

Slant Bed CNC Lathe is a high-precision, high-efficiency automated machine tool. Slant Bed CNC Lathe is equipped with multi-station turret or power turret, CNC Turning Center has a wide range of processing performance, and can process complex workpieces such as linear cylinders, oblique cylinders, arcs and various threads, grooves, worms, etc. Interpolation, circular interpolation various compensation functions, and play a good economic effect in the mass production of complex parts.

Product application industry

High-precision inclined bed CNC lathe TCK36A is suitable for automobiles, motorcycles, electronics, aerospace, petroleum and other industries. The inclined bed CNC lathe has high-efficiency and high-precision automatic processing. It adopts a 45-degree high-rigidity integral bed, high-precision spindle unit, and Taiwan line rails to ensure high rigidity of the whole machine. The center of the spindle is close to the operator, and it is more convenient to load and unload workpieces.

Video

Product Parameter

| Item | Unit | TCK36A |

| Maximum upper turning diameter of bed | mm | Φ360 |

| Maximum machining diameter on tool post | mm | Φ140 |

| Maximum processing length | mm | 300 |

| Spindle speed | rpm | 4000 |

| Spindle hole diameter | mm | 48 |

| Weight | KG | 2200 |

| Machine size | mm | 2200×1600×1850 |