PRODUCT

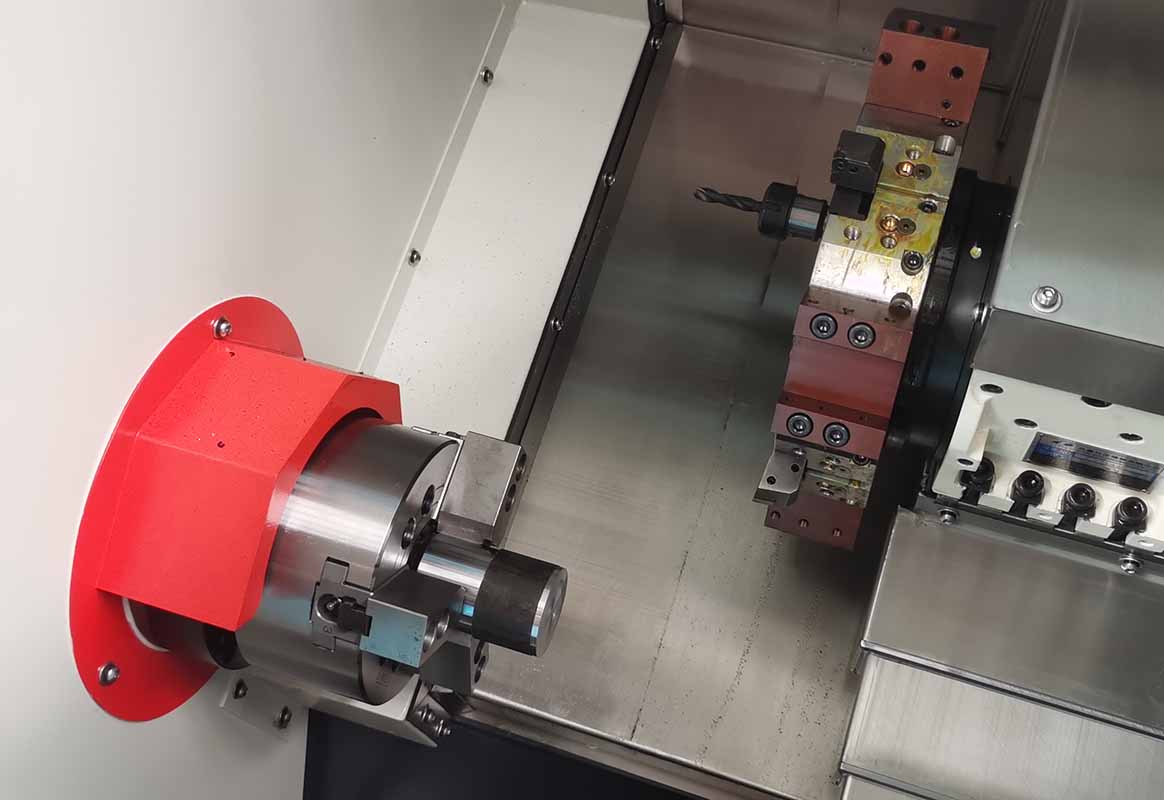

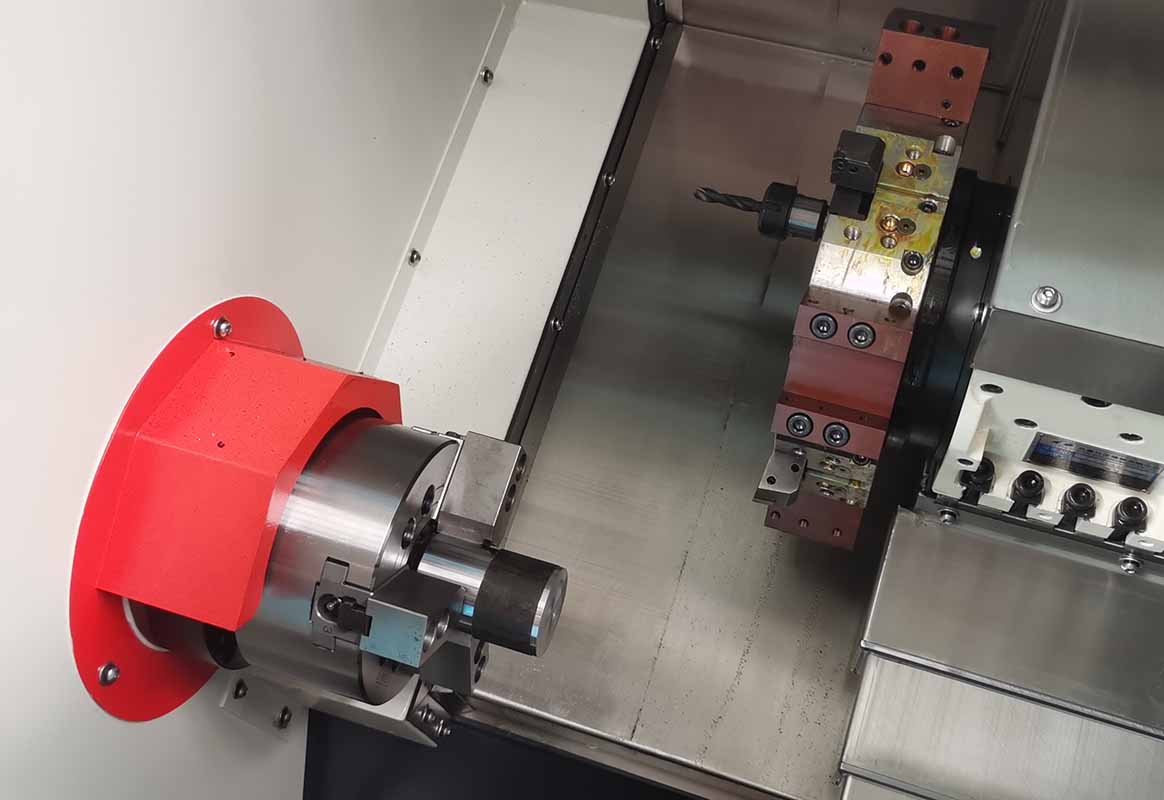

Slant bed CNC lathes are suitable for processing various materials, including metals, plastics, etc., and can complete processing tasks of various shapes.

Inclined bed CNC lathes are usually equipped with high-precision servo systems and precision ball screws to achieve high-precision machining requirements.

Advantage

Easy to cut: Slant bed CNC lathes The slant bed design makes the chips generated during the cutting process easy to fall off and not easy to get stuck on the workpiece or tool, which helps to improve processing efficiency.

Convenient operation: The inclined bed design makes it easier for operators to access the work area, making it easier to clamp workpieces, change tools and observe the machining process.

The tool is more stable: Due to the design of the inclined bed, the tool is more stable relative to the workpiece, reducing vibration and helping to improve cutting accuracy.

High degree of automation: Slant bed CNC lathes can be used with automated loading and unloading systems to achieve automated production and improve production efficiency.

Product application industry

Electronics industry: In the electronics industry, the processing of micro-parts is often required. These parts are usually required to manufacture electronic chips, connectors, etc. CNC lathes can be used for processing to meet the needs of the electronics industry.

Mold manufacturing: Molds are needed in various industries to produce plastic products, metal products, etc. CNC lathes can process complex-shaped molds, improving production efficiency and mold accuracy.

Shipbuilding industry: Shipbuilding produces a large number of metal structural parts, which requires CNC lathes to process various ship parts and improve the accuracy and quality of shipbuilding.

Video

Product Parameter

| Item | Unit | TCK36A |

| Maximum upper turning diameter of bed | mm | Φ360 |

| Maximum machining diameter on tool post | mm | Φ140 |

| Maximum processing length | mm | 300 |

| Spindle speed | rpm | 4000 |

| Spindle hole diameter | mm | 48 |

| Weight | KG | 2200 |

| Machine size | mm | 2200×1600×1850 |