PRODUCT

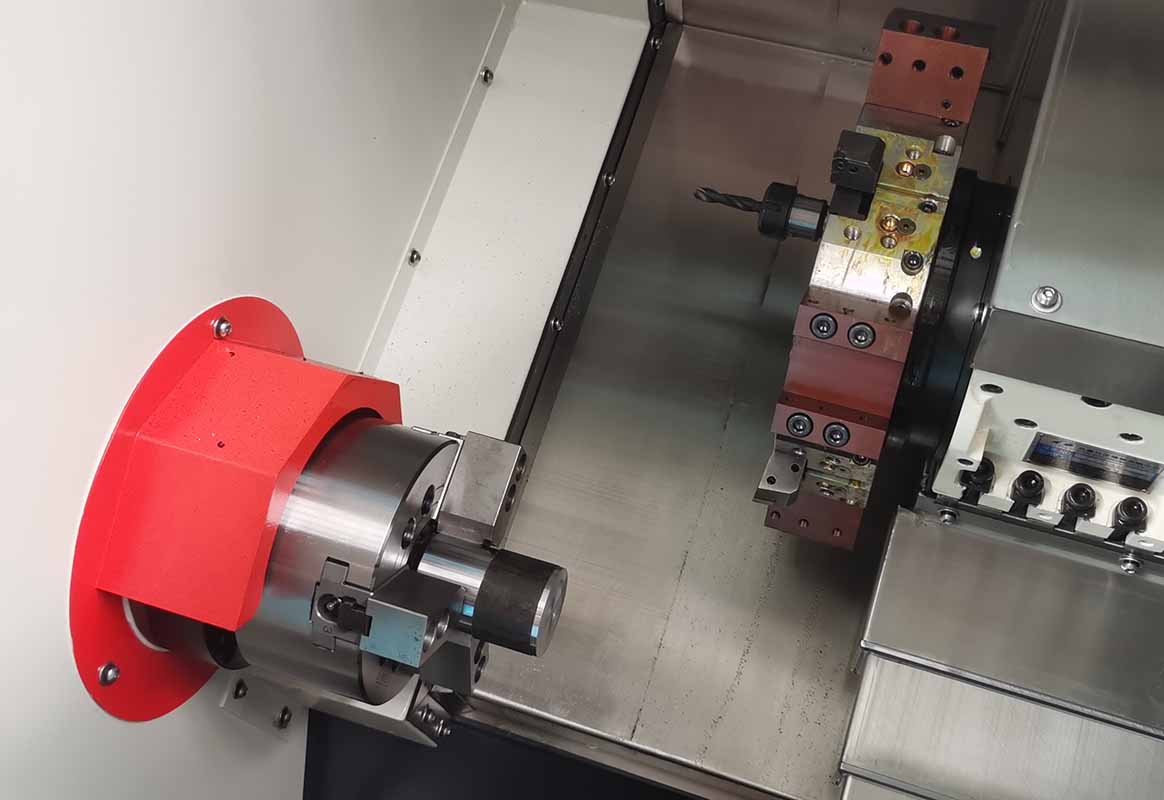

The inclined bed design makes it easier to discharge chips, while increasing the rigidity and stability of the machine tool and reducing the impact of thermal deformation on machining accuracy.

The machine tool uses high-quality cast iron and advanced heat treatment technology to ensure that the machine tool has high rigidity and high precision. Its guide rails are precisely ground and scraped to improve the machining accuracy and life of the machine tool.

Advantage

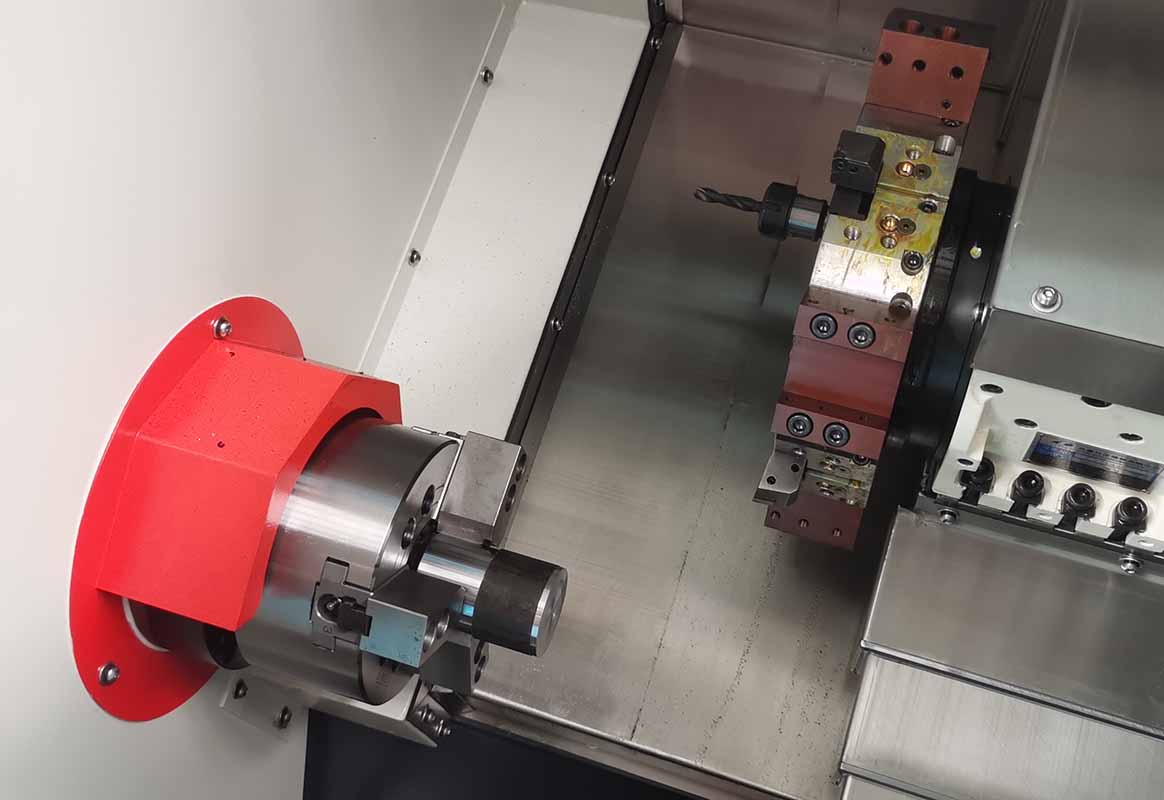

TCK36ASlant Bed CNC Lathe is equipped with an automatic tool changer and CNC system, which can automatically complete the processing of multiple processes, reduce tool change time, and improve production efficiency.

TCK36ASlant Bed CNC Lathe is equipped with a powerful CNC system, which can achieve precision processing of complex parts, support multiple programming methods, easy operation and user-friendly interface.

TCK36A machine tool can perform a variety of processing techniques, such as turning, drilling, tapping, etc., and is suitable for processing various complex shaft and disc parts.

Product application industry

The application of TCK36ASlant Bed CNC Lathe in the machinery manufacturing industry is used to process various shaft, disc, and housing parts in the manufacturing process of machine tools, construction machinery, agricultural machinery, etc.

In the electrical and electronic industries, TCK36ASlant Bed CNC Lathe can process small precision parts such as motor shafts, electronic connectors, connectors, heat sinks, etc.

The application of TCK36ASlant Bed CNC Lathe in the medical device industry is suitable for the production of high-precision medical device parts

Video

Product Parameter

| Item | Unit | TCK36A |

| Maximum upper turning diameter of bed | mm | Φ360 |

| Maximum machining diameter on tool post | mm | Φ140 |

| Maximum processing length | mm | 300 |

| Spindle speed | rpm | 4000 |

| Spindle hole diameter | mm | 48 |

| Weight | KG | 2200 |

| Machine size | mm | 2200×1600×1850 |