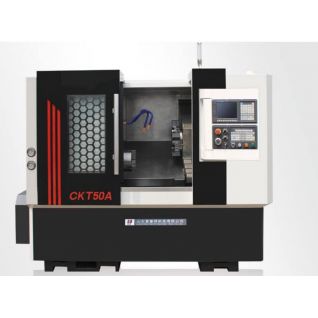

PRODUCT

CNC turning center has a high degree of automation and can achieve functions such as automatic feeding, automatic positioning, and automatic processing, which improves production efficiency and machining accuracy.

CNC turning center can be applied to the processing of various metals, plastics, and non-metallic materials, and can meet the needs of different fields and industries.

Features of Slant Bed CNC Turning Center TCK56A:

1.High-precision machining capability: Slant bed CNC lathe adopts high-precision servo motors and precision machining tools, which can achieve high-precision machining, suitable for machining parts with high precision requirements.

2.Multi-functional machining capability: Slant bed CNC lathe can achieve various machining processes such as turning, milling, drilling, tapping, and more, by using different cutting tools, which can meet different machining needs.

3.Flexibility and high efficiency: Slant bed CNC lathe has flexible machining methods and high-efficiency machining speed, which can achieve fast and efficient production processing.

Product Application Industry

Slant bed CNC turning centers are widely used in the motorcycle industry. Motorcycle components typically require high-precision machining, and slant bed CNC turning centers are characterized by high precision, high efficiency, and multifunctionality, making them ideal for producing motorcycle components.

Common motorcycle components, such as wheel hubs, shock absorbers, steering brackets, brake pads, and more, all require precise machining to meet the requirements of high-speed driving and safety. Slant bed CNC turning centers can perform multiple machining operations such as turning, drilling, tapping, milling, and more, to meet the machining needs of these components.

Video

Product Parameter

| Item | Unit | TCK56A |

| Max. swing dia. over bed | mm | Φ560 |

| Max. swing dia. over slide | mm | Φ300 |

| Max. processing length | mm | 500/1000 |

| Spindle speed | rpm | 4000 |

| Spindle hole diameter | mm | 65 |

| Weight | KG | 4250 |

| Machine size | mm | 2950/3450×1860×1850 |