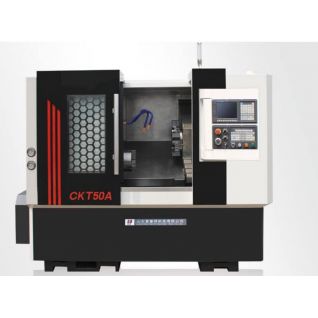

PRODUCT

ALHAASES CNC Slant Bed CNC Lathe The bed adopts 45° inclined rectangular sliding guide; 12 hydraulic turrets, Slant Bed CNC Lathe is widely used in various machining industries such as auto parts, hardware, and energy.

High rigidity and high stability

The integral 45° inclined L-shaped bed has high modal and high shock resistance, and realizes the high rigidity of the lathe.

High precision retention

The bed and the saddle are made of hard rails, which are ground after quenching, and the sliding surfaces are covered with soft wear-resistant belts, which can reduce friction and avoid crawling, ensuring high-precision retention.

Spindle thermal balance

The headstock and the sliding saddle are installed on the same angle plane, which reduces the distortion caused by the thermal deformation of the headstock and ensures the thermal balance of the main shaft.

High efficiency, heavy cutting

High-rigidity bed and spindle, large-span hard rail, and 12-station hydraulic turret ensure that the machine tool has the characteristics of high efficiency and heavy cutting.

Product Features:

1. The bed and base of Slant Bed CNC Lathe are heavy and have excellent shock resistance.

2. Inclined Bed CNC Lathe 45° inclined bed is designed to facilitate the operator to get on and off the workpiece, and it can ensure smooth chip removal.

3.inclined Bed CNC Lathe adopts T-shaped cutter plate to reduce tool change time, various cutter arrangement and combination, and improve production efficiency.

4.inclined Bed CNC Lathe X-axis has a long stroke and a large number of cutters.

Product Application Industry

CNC slant bed lathe better solves the problem of complex, precise, small batch and multi-variety parts processing. It is a flexible and high-efficiency automatic CNC slant bed lathe.

CNC turning lathe has the characteristics of high flexibility, high machining accuracy, stable and reliable machining quality, high productivity, and easy modernization of production management. CNC turning lathe It has a wide range of processing properties and plays a good economical effect in the mass production of complex parts.

Video

Product Parameter

| Item | Unit | TCK56A |

| Max. swing dia. over bed | mm | Φ560 |

| Max. swing dia. over slide | mm | Φ300 |

| Max. processing length | mm | 500/1000 |

| Spindle speed | rpm | 4000 |

| Spindle hole diameter | mm | 65 |

| Weight | KG | 4250 |

| Machine size | mm | 2950/3450×1860×1850 |