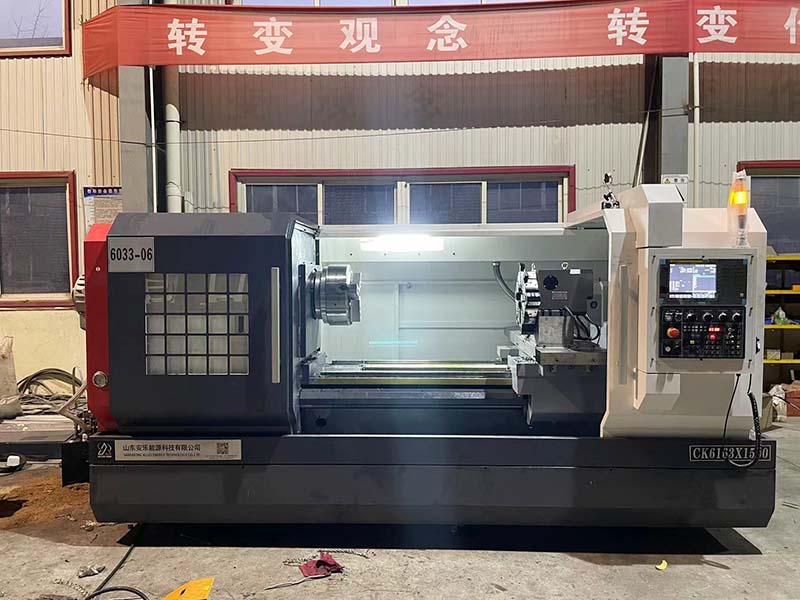

PRODUCT

CNC Lathe CK6163X1500

CK6163X1500 is a typical large CNC lathe, suitable for a variety of precision machining and heavy workpiece cutting tasks.

The processing range is large, and the maximum processing diameter of CK6163X1500 can reach 630mm, which is suitable for cutting tasks of larger diameter workpieces.

The processing length is 1500mm, which can meet the processing needs of long-axis workpieces.

High rigidity, the bed design is sturdy, with good shock resistance and high rigidity, suitable for heavy-load processing.

High precision, using CNC system, can ensure processing accuracy, suitable for cutting precision parts.

Features of Flat Bed CNC Lathe

The application of CK6163X1500 CNC system enables CK6163X1500 to quickly complete the processing tasks of complex parts.

Strong stability, precise guide rail and screw design ensure the stable operation of the machine tool and reduce the failure rate.

Wide adaptability, can process workpieces of various materials, such as steel, aluminum alloy, stainless steel, etc.

Product Application Industry

Horizontal cnc lathe machine is more and more widely used in the medical device industry. The manufacturing of medical devices requires high processing precision, high surface smoothness, and stable dimensions. Horizontal cnc lathe machine uses a numerical control system to control the tool to achieve high-precision processing , to meet the high-precision processing requirements of medical device manufacturing.

The horizontal cnc lathe machine has the characteristics of automatic production, which can realize automatic and efficient production, improve production efficiency, reduce manual intervention, and ensure the quality and stability of medical devices.

Video

Product Parameter

| Item | Unit | CK6163x1500 |

| Max swing over bed | mm | Φ630 |

| Maximum swing over slide | mm | Ф350 |

| Maximum cutting diameter | mm | Φ630 |

| Maximum processing length | mm | 1500 |

| X/Z axis maximum stroke | mm | 300/1500 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ104 |

| Machine weight | Kg | 3800 |