PRODUCT

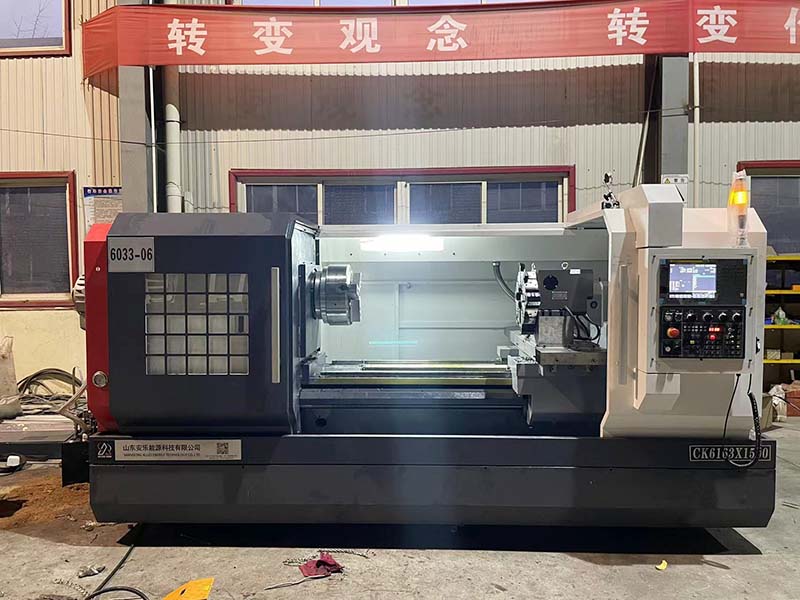

CK6163X1500 duty CNC lathe

CK6163X1500 is a heavy-duty CNC lathe widely used for processing large and complex parts. CK6163X1500 has significant competitive advantages in the field of heavy-duty machining and is suitable for production environments that require high precision and efficiency.

The bed length of CK6163X1500 is 1500 mm, which can process workpieces with larger diameters and is suitable for processing large parts.

The high-strength cast iron bed has good shock resistance and rigidity, ensuring stability and precision during processing.

Features of Flat Bed CNC Lathe

1.CK6163X1500Due to its stable structure and advanced CNC system, CK6163X1500 can achieve high-precision processing and meet the requirements of precision parts.

2.CK6163X1500 has high processing efficiency: the automation function and powerful cutting ability make it extremely efficient when processing large workpieces, suitable for mass production.

3.CK6163X1500 has strong adaptability: it can process workpieces of various materials, including steel, non-ferrous metals, etc., to meet various processing needs. The CNC system is easy to operate and has a friendly interface, which is easy for operators to master quickly.

Product Application Industry

1. CK6163X1500 is used in the energy industry to process large shaft and disc parts in wind turbines. It is used to process large parts such as drilling equipment and pipe connectors.

2. CK6163X1500 is used in aerospace to process high-precision, large-size parts such as aircraft engines and structural parts. It is used to produce core components of spacecraft such as satellites and rockets.

3. CK6163X1500 is used in shipbuilding to process large parts such as ship shaft systems and propellers to meet the requirements of high strength and high durability.

Video

Product Parameter

| Item | Unit | CK6163x1500 |

| Max swing over bed | mm | Φ630 |

| Maximum swing over slide | mm | Ф350 |

| Maximum cutting diameter | mm | Φ630 |

| Maximum processing length | mm | 1500 |

| X/Z axis maximum stroke | mm | 300/1500 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ104 |

| Machine weight | Kg | 3800 |