PRODUCT

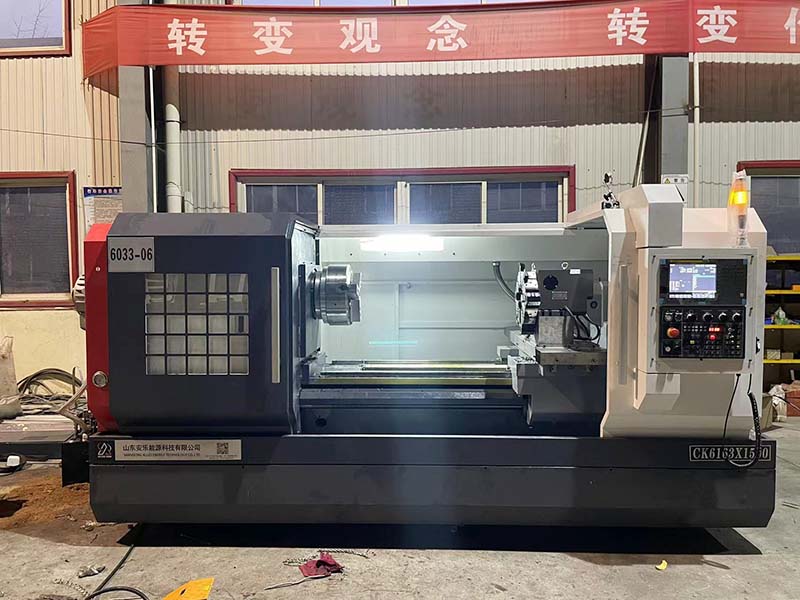

ALHAASES CNC lathe has the advantages of high precision, high efficiency, high automation and high flexibility.

CNC turning lathe can complete single piece production and small batch production. Using CNC turning lathe to process parts with complex shapes not only improves labor productivity and processing quality, but also shortens the production preparation cycle and reduces the requirements for workers' technical proficiency.

Therefore, CNC turning machine has become an important development direction to realize technological innovation and technological revolution in single-piece and small-batch production.

CNC turning center has the following characteristics:

1. CNC turning center has high processing precision and stable processing quality;

2. Multi-coordinate linkage can be carried out, and parts with complex shapes can be processed;

3. When the processing parts of the CNC turning center are changed, generally only the NC program needs to be changed, which can save production preparation time;

4. CNC Lathe Machines have high precision and high rigidity, can choose a favorable processing amount, and have high productivity (generally 3 to 5 times that of ordinary machine tools);

5. CNC Lathe Machines have a high degree of automation, which can reduce labor intensity;

Product Application Industry

CNC turning machine is widely used in automobile, aerospace, and military industries. Numerical control technology has developed rapidly in both hardware and software.

CNC turning machine is mainly used for cutting machining of inner and outer cylindrical surfaces of shaft parts or disk parts, inner and outer conical surfaces of arbitrary cone angles, complex rotary inner and outer curved surfaces, cylinders, and conical threads, etc., and can perform grooving, drilling, and reaming , Reaming and boring etc.

Video

Product Parameter

| Item | Unit | CK6163X1500 |

| Max swing over bed | mm | Φ630 |

| Maximum swing over slide | mm | Ф350 |

| Maximum cutting diameter | mm | Φ630 |

| Maximum processing length | mm | 1500 |

| X/Z axis maximum stroke | mm | 300/1500 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ104 |

| Machine weight | Kg | 3800 |