PRODUCT

small cnc lathe CK6130

K6130 CNC lathe is a kind of equipment widely used in the mechanical processing industry. It adopts high-rigidity structure and high-precision rolling guide rails to achieve high-precision processing requirements. It is equipped with advanced CNC system and supports multiple programming methods, which is convenient for operation and program modification. It can perform a variety of processing operations such as turning, milling, drilling, etc., and has strong adaptability. Automatic loading and unloading device can be optionally equipped to improve production efficiency.

The K6130 CNC lathe supports the use of a variety of tools to meet different processing needs.

Automation and CNC make the processing process faster and save labor costs.

Reduce human errors, and use the CNC system for precise control to reduce human operation errors.

Strong adaptability, can be used to process a variety of materials, such as metals, plastics, etc., and widely meet the needs of different industries.

Simplified operation, compared with traditional lathes, the operation is simpler and easier to learn and master.

CK6130 CNC Lathe Of Features

1. Wide processing range: It can process parts of various materials, such as steel, aluminum, copper, plastic, etc., with strong adaptability.

2. Cost saving: High-efficiency processing capacity and automation function reduce production cycle and labor cost, and improve production efficiency.

3. High reliability: The use of high-quality components and structural design ensures the long-term stable operation and low failure rate of the machine tool.

4. Suitable for small batch production: Due to its high precision and versatility, it is suitable for small batch and multi-variety production needs, with high flexibility.

CNC Lathe Specifications

| Item | Unit | CK6130 |

| Max swing over bed | mm | Φ300 |

| Maximum swing over slide | mm | Φ130 |

| Spindle hole diameter | mm | Φ48 |

| With hollow chuck pull rod through hole | mm | Φ40 |

| Spindle speed limit | rpm | 2200 |

| X stroke | mm | 280 |

| Z stroke | mm | 500 |

| X axis repeat positioning accuracy | mm | 0.01 |

| Z axis repeat positioning accuracy | mm | 0.01 |

| Dimensions (length × width × height) | mm | 1600×1100×1650 |

Standard:

CNC systems: GSK CNC systems

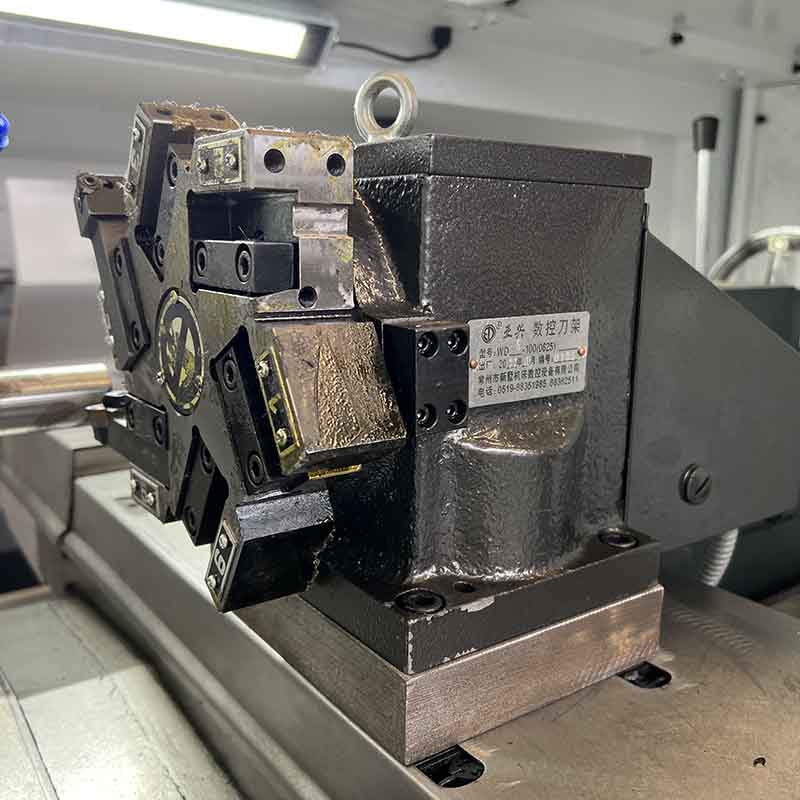

Turret: Four-station turret

Chuck: Manual three-jaw chuck

Optional:

CNC systems: Fanuc, Siemens and other CNC systems

Chuck: Hydraulic chuck

Turret: 6/8/12 station turret

Feeding device: Automatic Bar Feeder

Video