PRODUCT

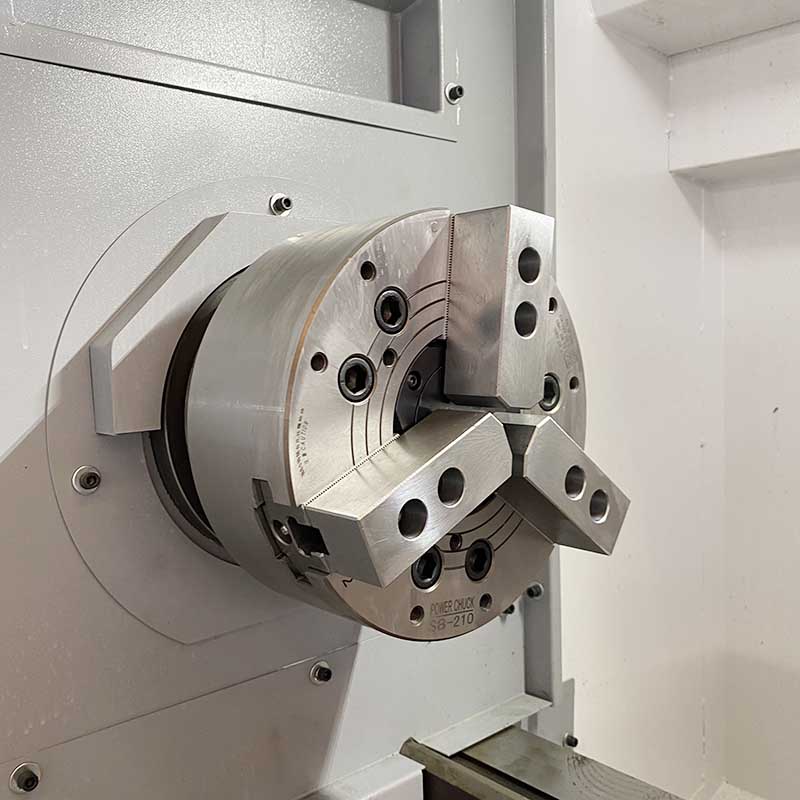

Automatic Flat Bed CNC Lathe CK6160X2000

CNC lathes are versatile manufacturing tools that are used in almost every industry that requires high precision and complex machining. They help increase production efficiency, reduce human error, and provide consistent product quality.

The CK6160X2000 flat bed CNC lathe has the characteristics of high precision, versatility, automation and reliability. It is suitable for various processing needs and is one of the important processing equipment in the manufacturing industry.

CK6160X2000 CNC lathes are generally manufactured with solid structures and high-quality materials to ensure long-term stable operation and reliability.

Features of CNC lathe

Flat bed structure: This type of lathe adopts a flat bed structure, with a flat and stable work surface, and is suitable for processing larger or longer workpieces. The flat bed structure helps maintain the stability and rigidity of the workpiece.

High-precision machining: The CK6160X2000 CNC lathe is designed for high-precision machining tasks to achieve precise dimensional and surface quality requirements. The accuracy and stability of the CNC system ensures processing quality.

Versatility: Lathes often feature multiple tool stations, allowing multiple machining operations such as turning, boring, tapping and grooving to be performed on the same workpiece. This increases productivity and reduces tool change time.

Product Application Industry

Sheet Metal Processing: CNC lathes are also widely used in sheet metal processing for cutting, bending and punching sheet metal components such as chassis, panels and frames.

Military industry and defense: CNC lathes are used to manufacture key components of military equipment and weapons systems, including artillery, tanks, aircraft and missiles.

Shipbuilding: In the shipbuilding process, CNC lathes are used to manufacture various hull components, propellers, and other critical structures.

Video

Product Parameter

| Item | Unit | CK6160x2000 |

| Max swing over bed | mm | Φ600 |

| Maximum swing over slide | mm | Ф310 |

| Maximum cutting diameter | mm | Φ600 |

| Maximum processing length | mm | 2000 |

| X/Z axis maximum stroke | mm | 300/2000 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |

| Machine size | mm | 4400x1700x1800 |