PRODUCT

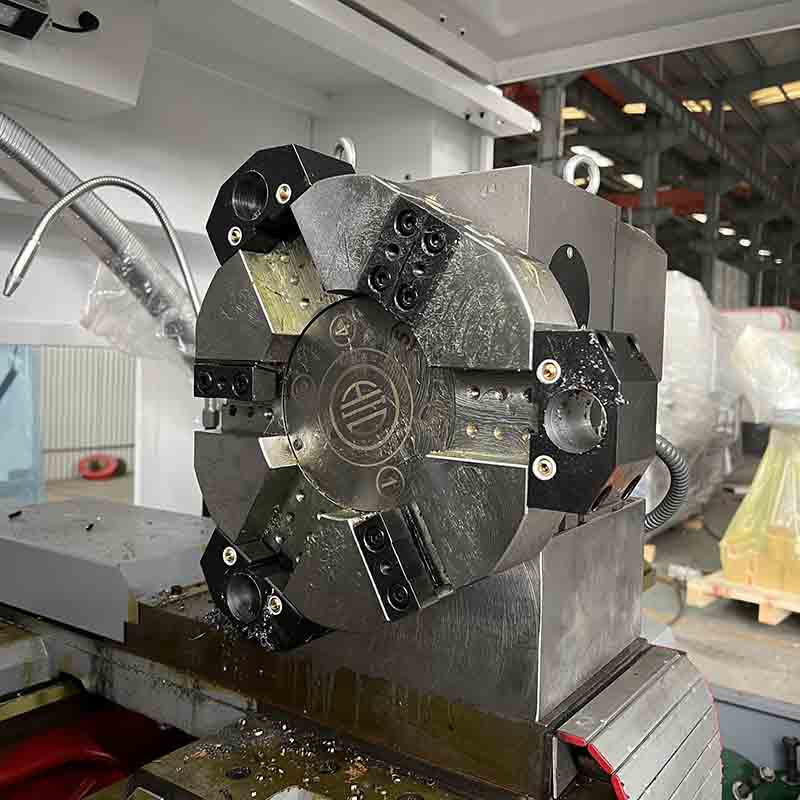

CK6160X1000 CNC lathe

CK6160X1000 is a common CNC lathe model, used for machining various shaft and disc parts, suitable for cutting a variety of materials. Through reasonable use and maintenance, CK6160X1000 CNC lathe can provide efficient and stable processing solutions for various machining industries.

CK6160X1000 is a common CNC lathe model, used for processing various shaft and disc parts, suitable for cutting a variety of materials.

CK6160X1000 CNC lathe uses high-precision ball screws and linear guides to ensure processing accuracy and repeat positioning accuracy. The machine bed is made of high-strength cast iron and has been aging treated. It has high rigidity and shock resistance and is suitable for heavy cutting.

Features

1. CK6160X1000 is equipped with advanced CNC system, supports G code programming, has high degree of automation, and is suitable for mass production.

2. CK6160X1000 is multifunctional and can complete various processing procedures such as turning, drilling, boring, thread cutting, etc. One clamping can complete multiple processes and improve processing efficiency.

3. CK6160X1000 is easy to operate. CNC lathes are generally equipped with a user-friendly operating interface. Operators can easily control the machine through the touch screen or buttons.

Processing Workpiece

1.CK6160X1000 is suitable for turning various general mechanical parts in mechanical processing.

2.CK6160X1000 is suitable for machining automobile shaft and disc parts, such as wheel hubs, bearing seats, etc. in automobile manufacturing.

3.CK6160X1000 is suitable for rough machining and finishing of mold parts in mold manufacturing.

Video

Product Parameter

| Item | Unit | CK6160x1000 |

| Max swing over bed | mm | Φ600 |

| Maximum swing over slide | mm | Ф310 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 1000 |

| X/Z axis maximum stroke | mm | 300/(1000/1500) |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | F82 (105/130) |

| Diameter of tailstock sleeve | mm | Φ75 |

| Machine size | mm | 2940x1400x1700 |