PRODUCT

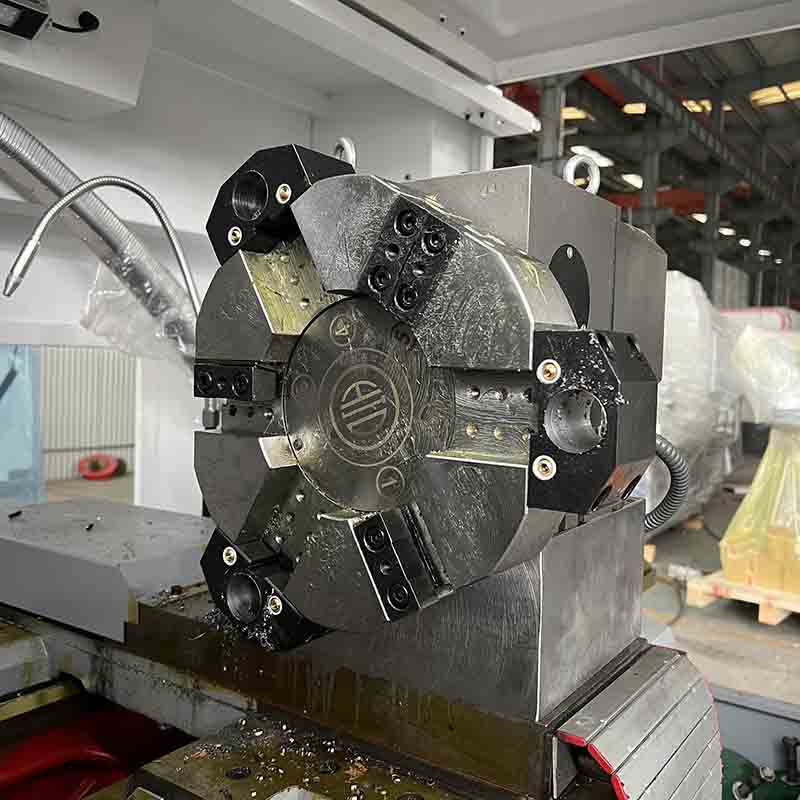

Flat Bed Horizontal CNC Lathe CK6160X1000

ALHAASES CNC lathes have high flexibility and are suitable for automatic processing of various types and small batches of parts. CNC military lathe can be used for both roughing and finishing, and can complete all or most of its processes in one clamping.

CK series Flat Bed CNC Lathe is suitable for processing all kinds of small and medium-sized shaft and disk workpieces. It has the characteristics of simple programming, reliable structure, convenient operation and high degree of automation.

Flat Bed Horizontal CNC Lathe is suitable for turning various internal and external cylindrical surfaces, conical surfaces, arc surfaces and other rotating surfaces, and for turning various threads. It is a high-efficiency CNC machining equipment commonly used in the machining field.

Horizontal CNC Lathe Machine Has The Following Characteristics:

1. CNC automatic lathe has high processing precision and stable processing quality;

2. Multi-coordinate linkage can be carried out, and parts with complex shapes can be processed;

3. When the processing parts of the horizontal cnc lathe machine are changed, generally only the NC program needs to be changed, which can save production preparation time;

4. Mini Metal Lathe Machines have high precision and high rigidity, can choose a favorable processing amount, and have high productivity (generally 3 to 5 times that of ordinary machine tools);

5. Mini Metal Lathe Machines have a high degree of automation, which can reduce labor intensity;

Product Application Industry

Horizontal cnc lathe machines are commonly used in industries such as oil and gas, automotive, aerospace, medical, electronics, mining, power plants, steel and paper mills, and shipbuilding.

CNC lathes can complete efficient, automatic and precise machining of cylinders, cones, stepped shafts, end faces, borings, grooving, threads, arc surfaces, etc., and can be widely used in mechanical instruments, motorcycles, burning appliances, light industry Single piece, small batch or batch production in electrical and other industries.

Video

Product Parameter

| Item | Unit | CK6160*1000 |

| Max swing over bed | mm | Φ600 |

| Maximum swing over slide | mm | Ф310 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 1000 |

| X/Z axis maximum stroke | mm | 300/(1000/1500) |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Ф82 (105/130) |

| Diameter of tailstock sleeve | mm | Φ75 |

| Machine size | mm | 2940x1400x1700 |