PRODUCT

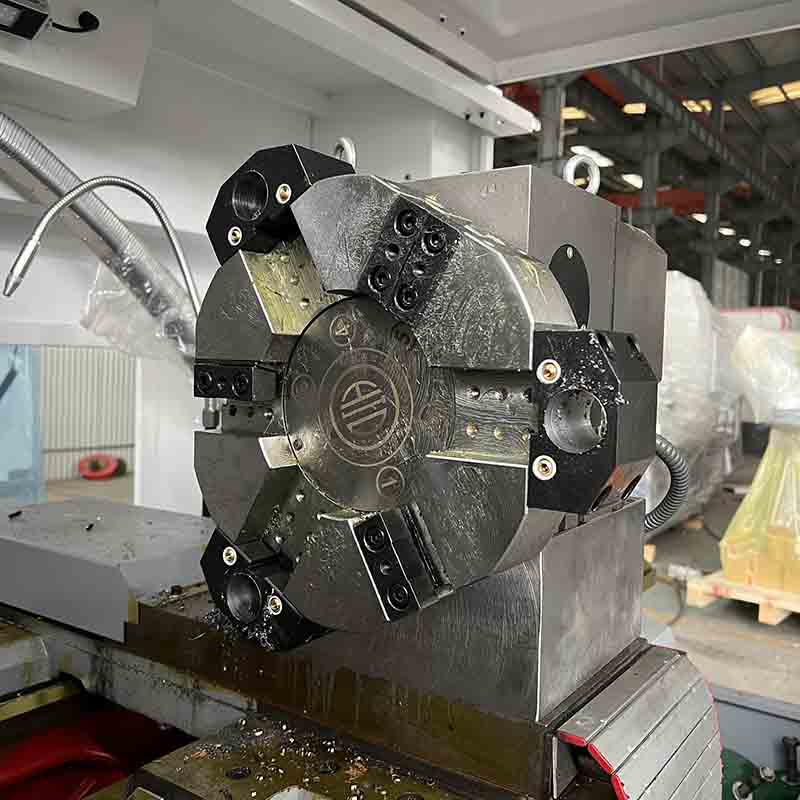

Flat Bed CNC Lathe For Metal CK6160X1000

ALHAASES CNC lathes have high flexibility and are suitable for automatic processing of various types and small batches of parts. CNC military lathe can be used for both roughing and finishing, and can complete all or most of its processes in one clamping.

The CK6160X1000 CNC lathe is suitable for processing a variety of different materials, including metals, plastics and composite materials. It can be used to produce various parts and workpieces, so it has a wide range of applications in manufacturing.

This type of CNC lathe is usually equipped with an intuitive operating interface that allows operators to easily set and control machining parameters.

Features

1. High-precision machining: This CNC lathe is designed for high-precision machining and can achieve high-precision machining and surface quality of workpieces. The precision and stability of the CNC system ensure the consistency of workpiece dimensions and geometry.

2. Versatility: CK6160X1000 CNC lathes are usually equipped with multiple tool stations, allowing multiple processing operations to be completed on the same workpiece, such as turning, boring, tapping and grooving. This increases productivity and reduces tool change time.

3. Automation: CNC lathes have automation functions, including automatic tool changing systems, automatic workpiece clamping and unloading, etc. These features reduce operator intervention, increase productivity, and reduce operational risk.

Processing Workpiece

Medical Device Manufacturing: Manufacturing medical devices and instruments requires high-precision and high-quality components. CNC lathes can produce precise medical device components such as prosthetics, surgical tools and implants.

Electronics manufacturing: CNC lathes are used to make housings, heat sinks, connectors and other components for electronic devices. They ensure the dimensional and shape accuracy of these components.

Energy Industry: CNC lathes are used in the energy industry to manufacture oil and gas drilling equipment, turbine units, nuclear power plant components, etc. to ensure efficient and reliable energy production.

Video

Product Parameter

| Item | Unit | CK6160x1000 |

| Max swing over bed | mm | Φ600 |

| Maximum swing over slide | mm | Ф310 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 1000 |

| X/Z axis maximum stroke | mm | 300/(1000/1500) |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | F82 (105/130) |

| Diameter of tailstock sleeve | mm | Φ75 |

| Machine size | mm | 2940x1400x1700 |