PRODUCT

Mini Flat Bed CNC Lathe CK6130

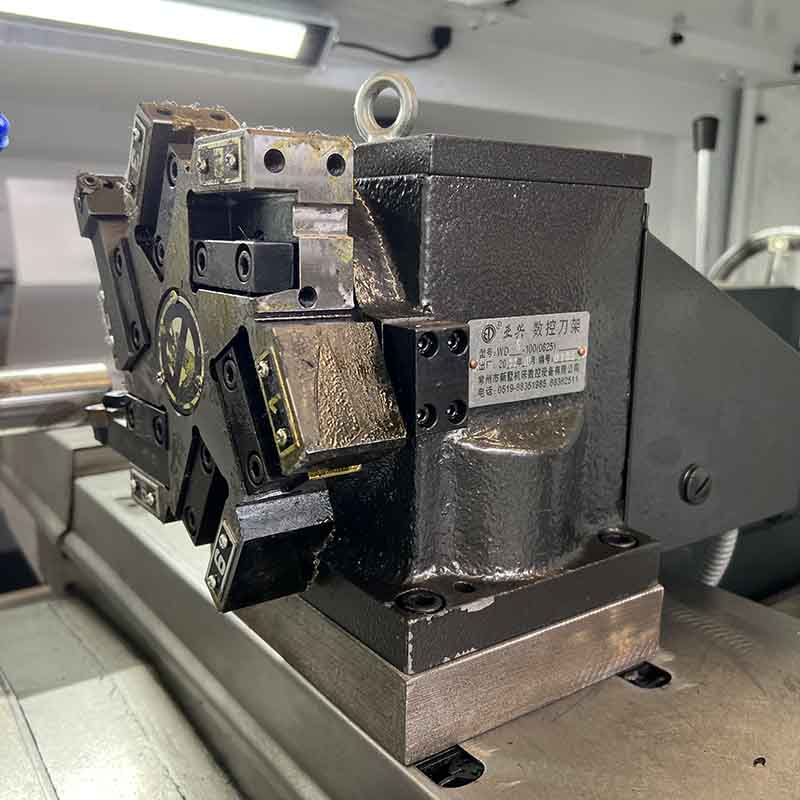

CNC lathe 3 axis can further improve production efficiency, and is equipped with a driven turret and a driven tool holder that can rotate the tool, which can perform drilling, milling and tapping on any part of the end face and circumference. Almost all processing can be done at one time. Clamping is completed.

High-speed CNC lathe 3 axis, manual scraping between the headstock and the bed, tailstock, pallet and other joint surfaces, the whole machine is detected by laser interferometer, which can effectively ensure the positioning accuracy of Z-axis and X-axis , Repeated positioning accuracy, backlash and stability of the machine tool. CNC lathe 3 axis spindle is driven by servo motor. CNC lathe 3 axis can realize various processes such as turning, drilling, etc. for shafts, discs, special-shaped parts and other parts of various materials, and is suitable for efficient processing and manufacturing of small parts.

Advanced overall design

CNC metal lathe has a reasonable rib plate arrangement to make the bed with high rigidity and stability, good chip removal and waterproof performance, single-spindle design, no need for manual shifting, and the speed can be infinitely variable.

High-efficiency machining

The main motor of CNC metal lathe adopts a high-torque variable-frequency motor, and with the rigidity of the spindle, it can meet the requirements of strong cutting and high-precision machining at the same time.

Product application industry

CNC automatic lathe has high-precision high-speed cutting function, which can complete efficient, automatic and precise machining of cylindrical, conical, stepped shaft, end face, boring, grooving, thread, arc surface and other shapes. CNC automatic lathe also has double-sided turning. function, the workpiece is clamped from the middle, and both ends are processed at the same time. CNC automatic lathe is mainly used for machining shaft parts with good coaxiality.

Video

Product Parameter

| Item | Unit | CK6130 |

| Max swing over bed | mm | Φ300 |

| Maximum swing over slide | mm | Φ130 |

| Spindle hole diameter | mm | Φ48 |

| With hollow chuck pull rod through hole | mm | Φ40 |

| Spindle speed limit | rpm | 2200 |

| X stroke | mm | 280 |

| Z stroke | mm | 500 |

| X axis repeat positioning accuracy | mm | 0.01 |

| Z axis repeat positioning accuracy | mm | 0.01 |

| Dimensions (length × width × height) | mm | 1600×1100×1650 |