PRODUCT

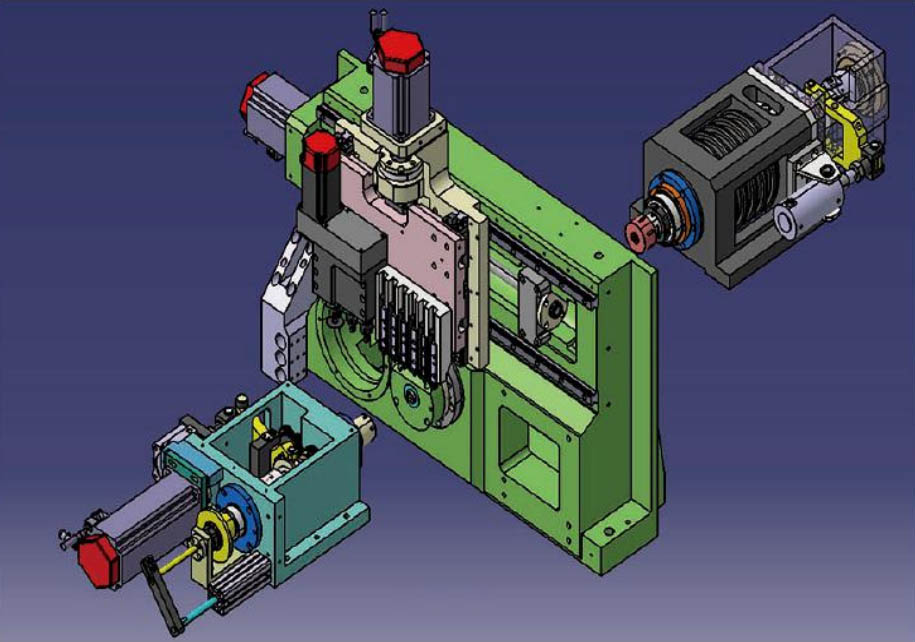

SL125 Automatic Swiss Type Lathe

The Swiss lathe is a high-precision automatic lathe widely used in precision manufacturing, especially in the processing of small parts. Its working principle is different from that of traditional lathes. It can improve processing efficiency and precision by moving materials and cutting tools at the same time.

Swiss lathes are designed to process small parts with extremely high precision, usually with errors controlled to the micron level. This makes them ideal for medical devices, watches, aerospace, electronic components and other fields.

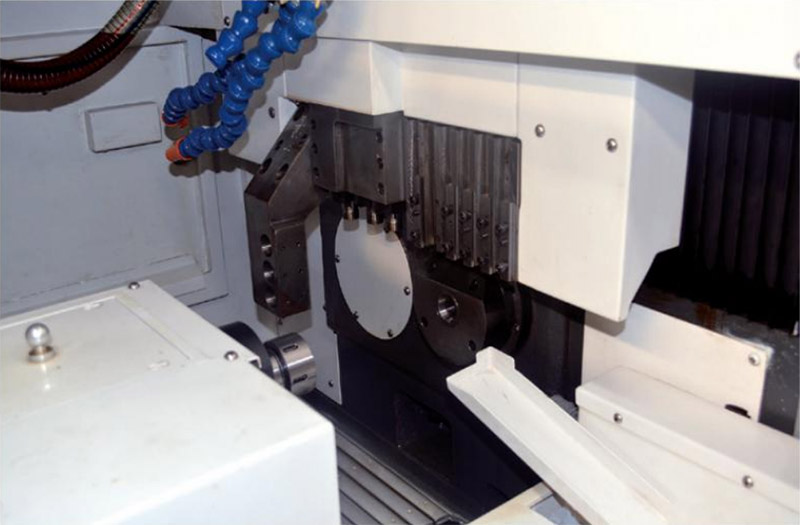

Swiss lathes use a guide sleeve to support the workpiece, and only a very small part of the workpiece is exposed during processing. In this way, the deflection or vibration of the workpiece is reduced, thereby improving the accuracy and stability of the processing, which is especially suitable for the processing of slender parts.

Automatic Swiss Type Lathe SL125 Features

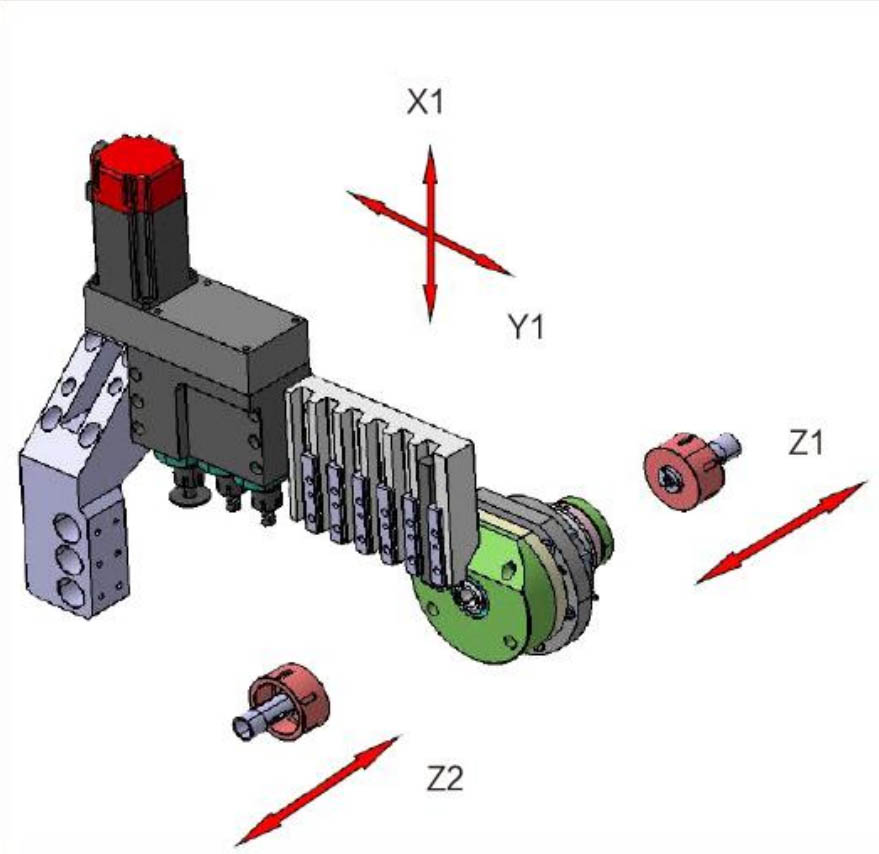

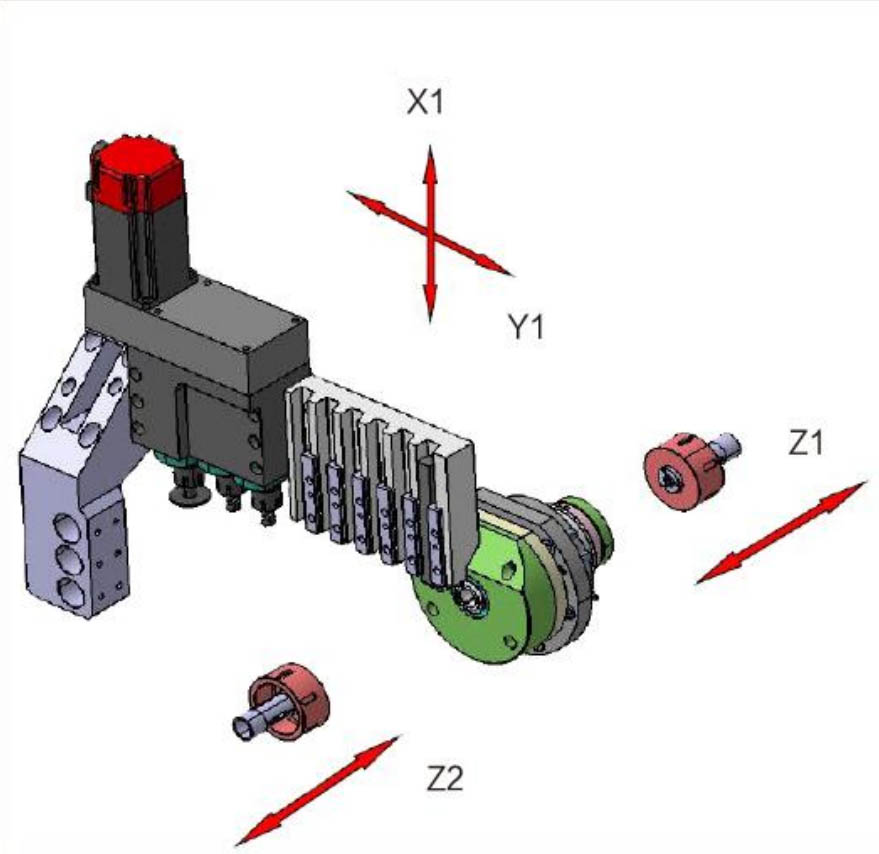

Swiss lathes can easily handle complex geometries and multi-process machining because they can perform multi-axis control at the same time, and can even complete multiple surface machining tasks in one clamping, which greatly improves production efficiency.

Swiss lathes are usually equipped with automatic feeding systems, which can achieve long-term unattended continuous production. This is very advantageous for small, high-precision parts produced in large quantities

Because Swiss lathes can handle multiple machining steps at the same time and support rapid tool switching, this reduces the need for secondary machining of parts, further saving time and cost.

Product application industry

1. Medical devices, application scenarios: Swiss lathes are often used to produce highly precise small medical devices and instruments.

2. Aerospace, application scenarios: used to produce lightweight and high-precision small parts.

3. Electronic components, application scenarios: Swiss lathes are very suitable for producing miniature and complex-shaped electronic components.

Video

Product Parameter

| Item | Unit | SL125 |

| Max.Turning Diameter | mm | Φ16 |

| Main Spindle Stroke | mm | 150 |

| Rapid traverse speed | m/min | 24 |

| O.D Tools | rpm | 6X[口12x12] |

| I.N Tools | mm | 3X[Φ25-ER16] |

| Weight | KG | 3,000 |

| Machine size | mm | 1985 x 1321 x 1692 |