PRODUCT

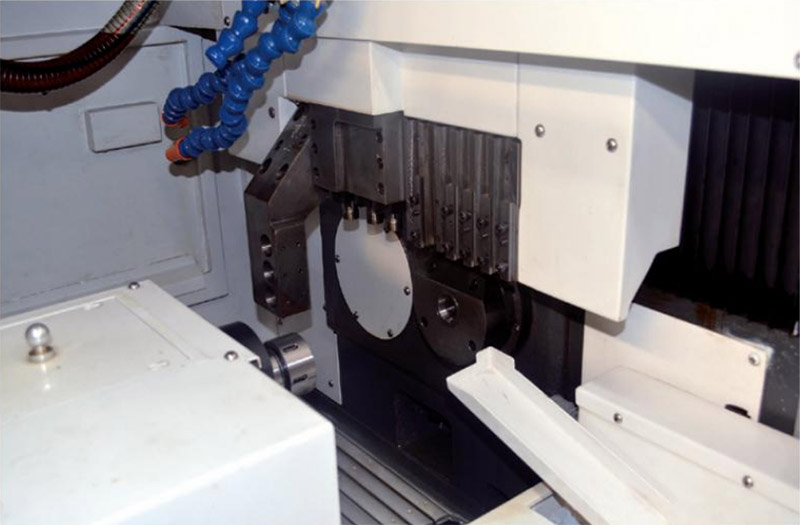

The CNC Swiss Type Lathe can process a wide variety of materials, such as stainless steel, titanium alloys, copper alloys, aluminum alloys, plastics, and more.

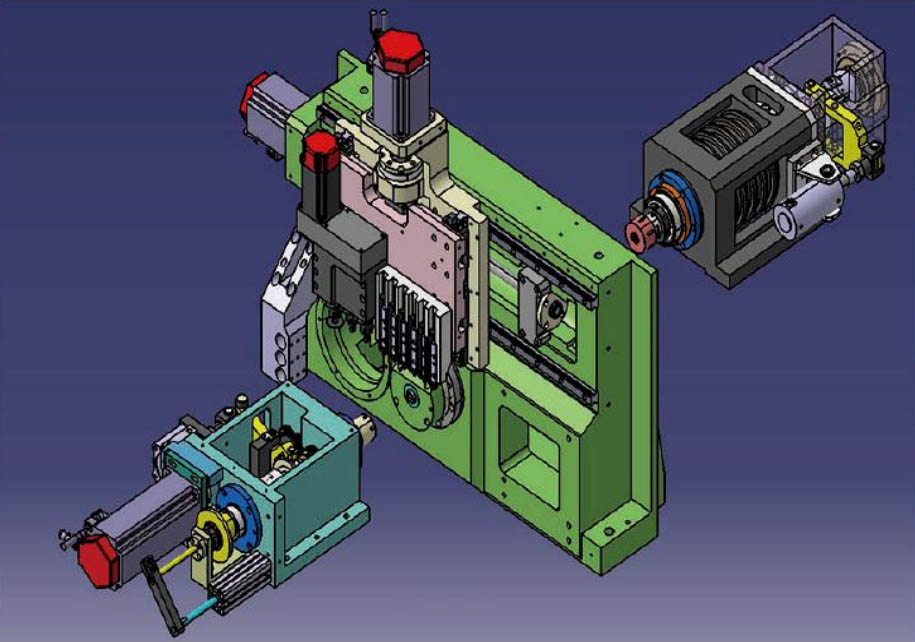

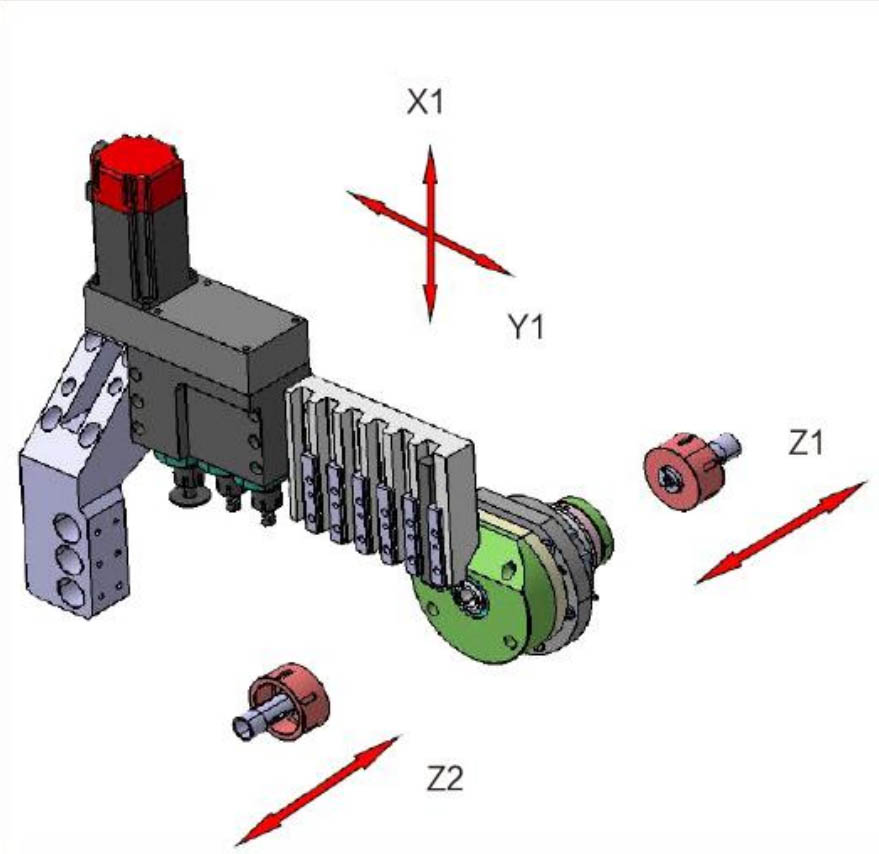

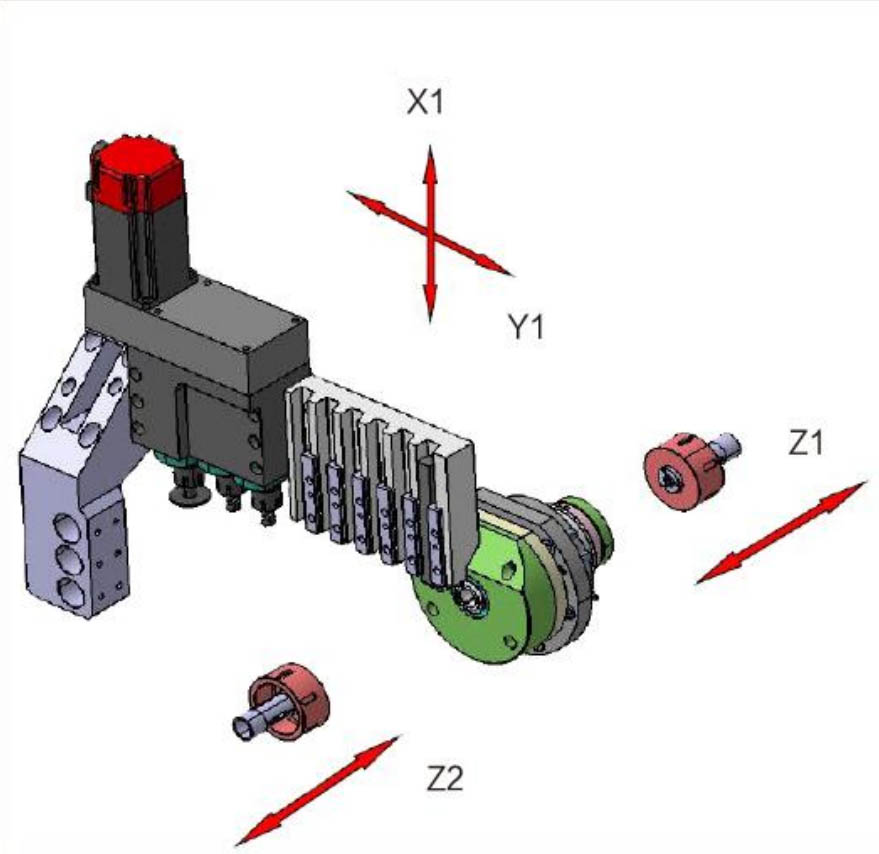

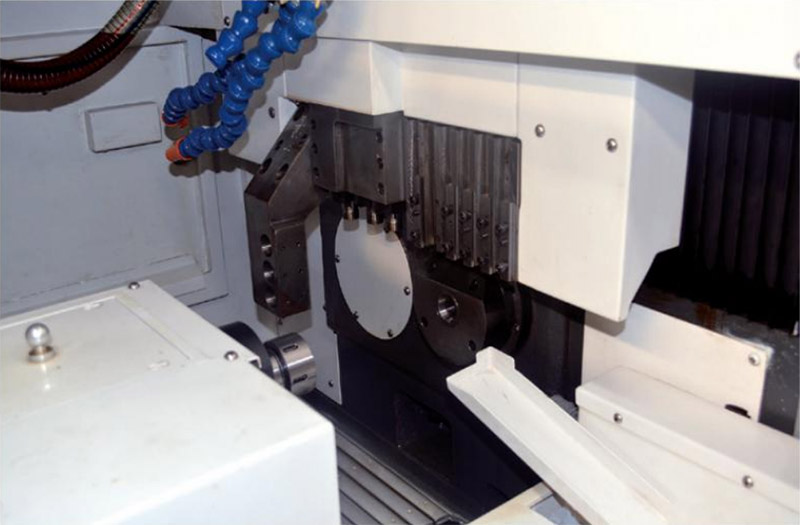

Equipped with a rotary tool turret and multi-axis control system, the CNC Swiss Type Lathe enables continuous machining of multiple operations, reducing the need for process transfers and improving machining efficiency.

Automatic Swiss Type Lathe SL125 Features

1.High-precision machining: The Automatic Swiss Type Lathe adopts sliding guide rails, which can maintain high precision machining even at high rotational speeds.

2.Suitable for long and slender workpieces: The main spindle structure of the Automatic Swiss Type Lathe is unique and can accommodate long and slender workpieces.

3.High degree of automation: The Swiss Type Lathe is equipped with an automatic feeding system and automated workpiece handling system, allowing for automatic completion of various complex processes, thus improving production efficiency.

Product application industry

1. Precision Machinery Manufacturing: The CNC Swiss Lathe is suitable for manufacturing various precision mechanical parts, including watches, clocks, timers, instruments, optical instruments, and more.

2. Medical Devices: The CNC Swiss Lathe can be used for processing and manufacturing various medical device components, such as artificial heart valves, artificial skeletal joints, and more.

3. Aerospace: The CNC Swiss Type Lathe can be used for processing and manufacturing various aerospace components, such as turbine blades, engine parts, missile components, and more.

Video

Product Parameter

| Item | Unit | SL125 |

| Max.Turning Diameter | mm | Φ16 |

| Main Spindle Stroke | mm | 150 |

| Rapid traverse speed | m/min | 24 |

| O.D Tools | rpm | 6X[口12x12] |

| I.N Tools | mm | 3X[Φ25-ER16] |

| Weight | KG | 3,000 |

| Machine size | mm | 1985 x 1321 x 1692 |