PRODUCT

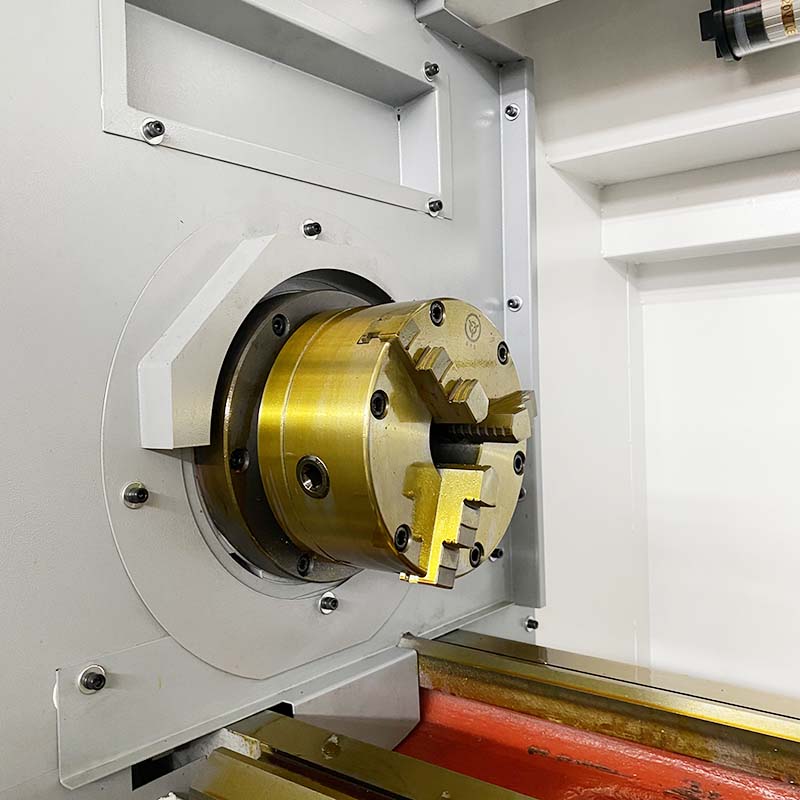

cnc turning machines CK6140X1000

CNC turning machines CK6140X1000 is a machine that controls lathes for processing through computer programs. It combines the advantages of traditional lathes and CNC technology, can achieve high-precision and high-efficiency processing, and is suitable for mass production of complex parts.

CK6140X1000 is computer controlled, so it can achieve extremely high processing accuracy.It can also achieve continuous processing with high efficiency and improve production efficiency.

CK6140X1000 reduces the error and labor intensity of manual operation. It can process complex shapes and diversified workpieces.

CNC Lathe CK6140X1000 Features:

1. The CK6140X1000 CNC lathe has a high degree of automation, and can realize functions such as automatic loading and unloading, automatic measurement and automatic compensation, which further improves the automation level of production.

2. The CK6140X1000 has a user-friendly human-machine interface. Modern CNC lathes are generally equipped with a graphical control interface, which is simple and intuitive to use, making it easier for workers to learn and use.

3. The CK6140X1000 CNC system is equipped with built-in fault diagnosis and alarm functions, which is convenient for timely detection and elimination of faults, and makes maintenance convenient and fast.

CNC Lathe Application Industry:

CK6140X1000In the mold manufacturing industry, mold manufacturing requires processing of complex curved surfaces and cavities. CNC lathes can achieve high-precision mold processing and improve the quality and life of molds.

CK6140X1000In the manufacturing of electronic and communication equipment, many parts in electronic and communication equipment, such as connectors, housings, microwave devices, etc., require high precision and small size. CNC lathes can meet these processing requirements.

CK6140X1000In the energy industry, CNC lathes are used to process parts of various energy equipment, such as the main shaft of wind turbines, parts of nuclear power plant equipment, etc. These parts usually require high-precision and high-strength materials

Video

Product Parameter

| Model | CK6140x1000 | |

| Processing capacity | Maximum turning diameter of bed | 400mm |

| Maximum turning diameter on the tool post | 220mm | |

| Center distance | 1000mm | |

| Rail width | 360mm | |

| X stroke | 250mm | |

| Z-stroke | 900mm | |

| Skateboard | Fast moving speed of carriage | X/Z:5/8m/min |

| Repeatability | Z: 0,013 mm X: 0,012 mm | |

| PACKING(L*W*H) | 2350x1400x1800mm | |