PRODUCT

CNC Turning Machine CK6140X750

CK6140X750 This model of CNC lathe has high-precision processing capabilities and can meet the processing needs of complex parts. The structure is reasonably designed, has good stability, and can maintain processing accuracy for a long time. The use of advanced CNC system can achieve fast and efficient processing and improve production efficiency.

The user-friendly interface and convenient operation of CK6140X750 make it easy for operators to get started, reducing training time and costs.

CK6140X750 also has a variety of processing functions, suitable for processing parts of various shapes and sizes. It uses high-quality materials and advanced manufacturing processes, and has a long service life and reliability.

1.CK6140X750 adopts high-strength cast iron bed, which has excellent rigidity and vibration resistance, ensuring long-term stability. The guide rail adopts high wear-resistant materials and precision processing technology to ensure long-term stability and precision.

2.CK6140X750 has a friendly user interface, simple human-machine interface design, convenient operation, easy to learn and use. It supports a variety of programming methods, including manual programming and automatic programming, to meet the needs of different users.

3.CK6140X750 has a wide range of processing, suitable for turning, boring, drilling, reaming and other processing technologies to meet the processing needs of different parts. And according to customer needs, it can be equipped with various optional accessories, such as automatic feeder, tailstock, center frame, etc., to further expand the function of the equipment.

STANDARD CONFIGURATION

1. System:GSK980TB3

2. Pneumatic collets.

3. Gang Type Tool.

4. Cooling system.

5. Lighten system.

6. Automatic lubrication system.

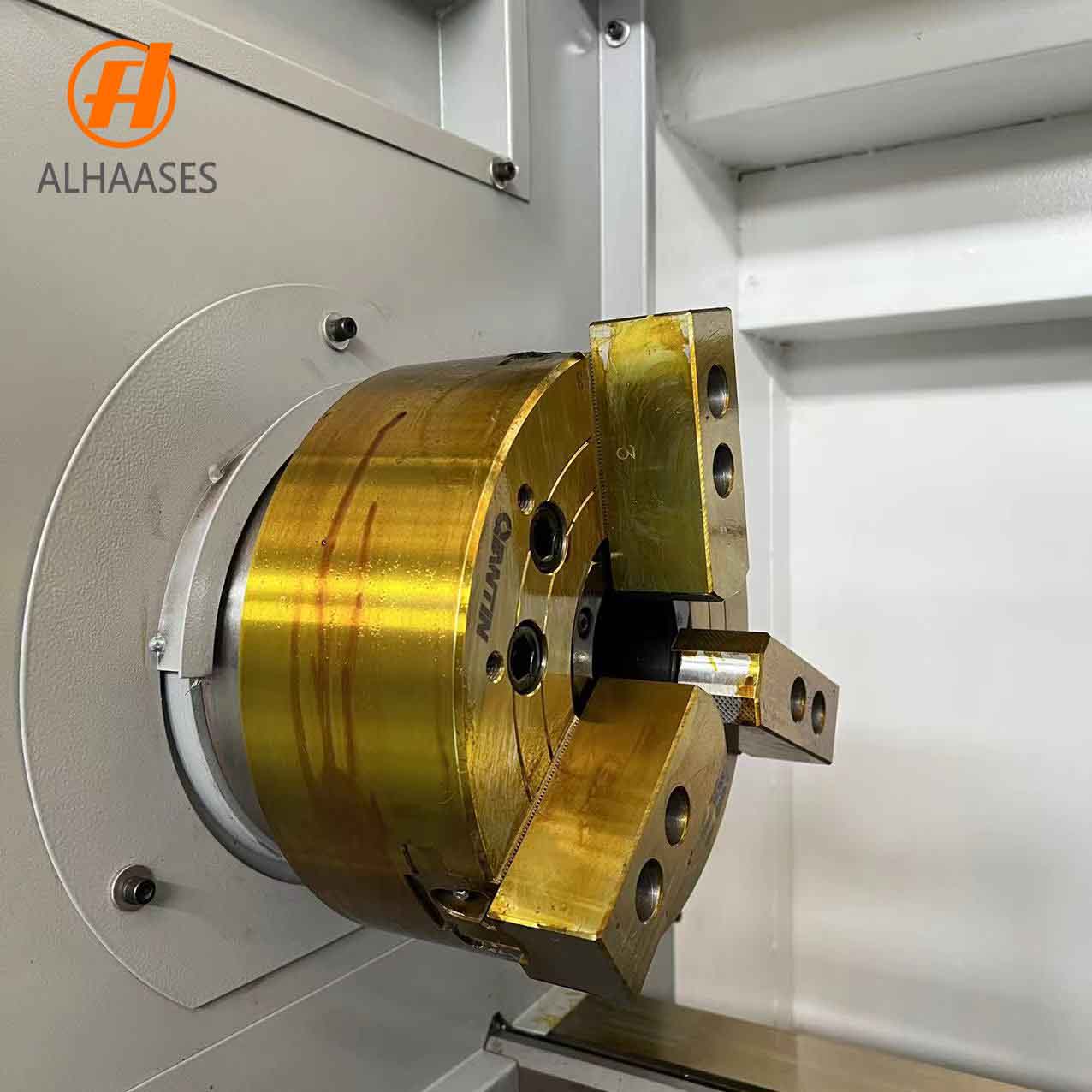

7. Three-jaw manual chuck

8. Vertical four-station tool holder

OPTIONAL CONFIGURATION

1. CNC system: Siemens, Fanuc, KND.

2. Hydraulic chuck, pneumatic chuck.

3. 4/6/8station electric tool post.

4. Automatic bar feeder.

5. Device for automatic feeding (bar feeder)

6. Chip Conveyor

7. Parts catcher

8. Hydraulic tailstock

Product application industry

CNC turning centers are used for machining equipment parts in the oil and gas industry, such as pipes, valves, and drill bits.

CNC turning centers find extensive applications in the defense industry for manufacturing weapon systems, naval vessel components, missile parts, and more.

CNC turning centers are widely utilized in general machinery manufacturing for various part machining, including gears, bearings, threads, and more.

Video

Product Parameter

| Model | CK6140x750 | |

| Processing capacity | Maximum turning diameter of bed | 400mm |

| Maximum turning diameter on the tool post | 220mm | |

| Center distance | 750mm | |

| Rail width | 360mm | |

| X stroke | 250mm | |

| Z-stroke | 900mm | |

| Skateboard | Fast moving speed of carriage | X/Z:5/8m/min |

| Repeatability | Z:0.013mm X:0.012mm | |

| PACKING(L*W*H) | 2350*1400*1800mm | |