PRODUCT

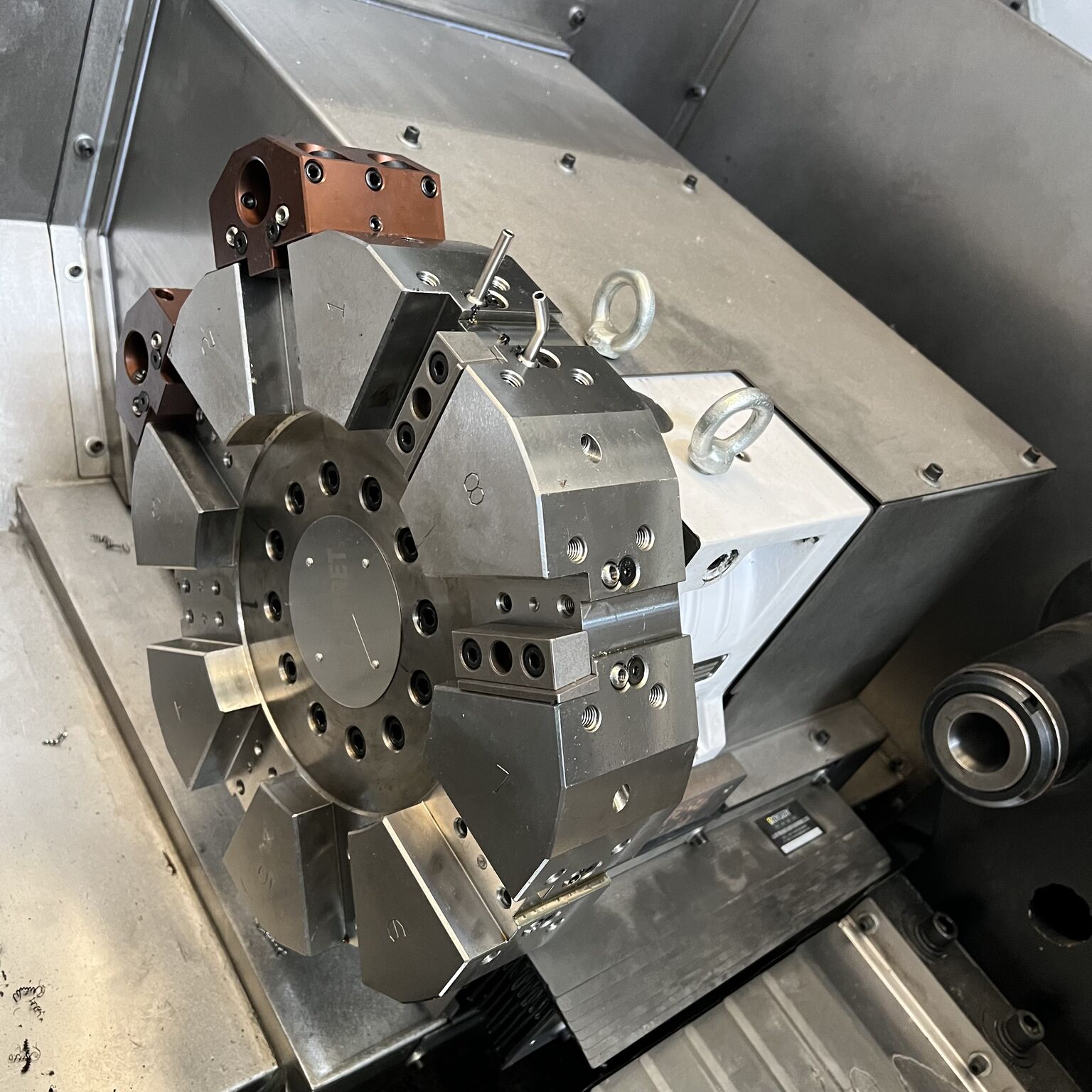

Slant Bed CNC Lathe FCK50 For Metal

Brand - ALLESCNC

Model - FCK50

Dimensions - 2250x1005mm

Price - $29,999(Standard Edition)/$31,499(Pro Edition)

Availability - 400 pieces of inventory available for sale every month

Certification - Meeting CE Standards in Terms of Quality & Safety

Payment Method - T/T/ Credit Cards

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

Slant bed CNC lathes are generally designed for high-precision, high-efficiency cutting. Such characteristics make them suitable for manufacturing environments that require a high degree of automation and production efficiency, such as mass production and complex parts processing.

The inclined bed structure improves the rigidity of the machine tool and makes it more stable. This is critical to maintaining machining accuracy under high speed and high cutting force conditions.

Features

Rigid structure: The inclined bed design provides stronger machine tool rigidity, helping to improve stability and machining accuracy.

High speed and efficiency: CNC technology makes operations more efficient, enables rapid processing, and improves production efficiency.

Multi-axis control: Equipped with multi-axis control function, it can control different motion axes of the workpiece at the same time to achieve a variety of processing operations.

Automation function: Equipped with automatic tool changing, automatic measurement and automatic compensation functions to reduce manual intervention and improve the level of automation.

Widely applicable: Suitable for processing various metal materials, including iron, copper, aluminum, etc., and can meet the processing needs of different industries.

Precision machining: The high-precision control of the CNC system enables precision machining, which is suitable for processes with high requirements on size and surface quality.

Product Parameter

| Item | Unit | FCK50 |

| Maximum slewing diameter on bed inner protection | mm | Φ560 |

| Turning diameter | mm | Φ500 |

| Turning length | mm | 500 |

| Spindle speed range | mm | 100-3000 |

| X-axis travel | mm | 280 |

| Z axis travel | mm | 550 |

| Machine frame dimensions | mm | 2250x1005 |

| Machine frame weight | kg | 2400 |

FCK50 Slant Bed CNC Lathe – Standard and Optional Configurations

Standard Configuration

Maximum Turning Diameter – Ø400 mm, Maximum Machining Length 500–600 mm (customizable).

Hydraulic Chuck – Reliable workpiece clamping.

Tailstock – Optional hydraulic/manual for support of long workpieces.

8-Station Electric Tool Turret – Standard for efficient turning operations.

Servo Drive System – High responsiveness and precise control.

Precision Ball Screws & Linear Guides – Ensures smooth and accurate motion.

CNC Control System – GSK systems.

Spindle Motor – Standard 3 kW (optional higher power available).

Optional Configurations

12-Station Electric Tool Turret – For increased tooling flexibility.

C-Axis & Live Tooling – Enables turn-mill combined operations for complex parts.

High-Speed Spindle – For faster cutting and improved productivity.

Additional Tailstock & Accessories – Hydraulic tailstock, steady rest, custom chucks.

Advanced CNC Systems – Optional upgrades to high-end FANUC, Siemens, or KND systems.

Coolant & Chip Removal Systems – Optional flood coolant, chip conveyor, or mist systems.

Product Application Industry

Parts manufacturing: High-precision CNC lathes are used to produce various mechanical parts, including shaft parts, gears, etc.

Mold processing: High-precision CNC lathes are suitable for manufacturing molds and can accurately cut and engrave complex shapes.

Aerospace: Slant body CNC lathes are used in the aerospace field to manufacture high-precision aircraft parts.

Automobile Manufacturing: CNC lathes are used to produce auto parts such as engine parts, wheel axles, etc.

Electronic parts processing: 3-axis CNC lathes are suitable for processing small, precise electronic parts.

Medical Equipment Manufacturing: 3-axis tilt CNC lathes are used to manufacture metal parts for medical equipment, ensuring high precision and quality.

Video

Maintenance and Care

Proper maintenance and care are essential to ensure the long-term performance, precision, and reliability of your FCK50 Slant Bed CNC Lathe, whether you are a beginner or an experienced operator.

Control Cabinet Placement – Place the control cabinet in a well-ventilated area, away from high temperatures, to prevent electrical component failure.

Machine Location – Ensure the lathe is installed in a dry, ventilated area to protect mechanical components from moisture and corrosion.

Stable Power Supply – Equip the machine with a reliable voltage stabilizer and ensure proper grounding of the system for safe operation.

Data Transfer – Avoid using networked computers to transfer files directly to the CNC system, as this may cause system errors.

Avoid Overloading Work Area – Do not place heavy, magnetic, or corrosive items on the machine bed or headstock.

Lubrication – Add appropriate lubricants to the ball screws, guideways, and rack systems at least once a month. Many machines are equipped with manual or electric oilers to simplify the process.

Check and Clean Moving Components – Regularly clean the ball screws, spindle, and guideways, and replace or replenish lubricants to minimize wear and maintain smooth operation.

Prevent Localized Wear – Avoid keeping the machine working on the same area of the bed for prolonged periods to ensure even lubrication and reduce uneven wear on guideways and screws.

Inspect Fasteners and Wiring – Periodically check for loose screws or wiring connections and tighten as needed to ensure accuracy and reliability.

Maintain a consistent lubrication schedule to extend the service life of moving parts.

Regularly monitor and clean the spindle, turret, and tailstock to ensure smooth operation and precision.

Keep the workspace organized to prevent foreign objects from damaging the machine or affecting machining quality.

Proper maintenance not only prolongs the life of your FCK50 CNC Lathe but also ensures stable machining accuracy and safe operation for years to come.