PRODUCT

CNC lathes are often capable of highly precise machining because their movements are controlled by computer programs and are not affected by human factors.

By modifying the control program, CNC lathes can adapt to different processing requirements, thereby increasing production flexibility.

CNC lathes are usually equipped with automatic tool changing systems, automatic measurement and correction functions, which reduce the need for manual intervention and improve production efficiency.

Features

Stable structure: The inclined bed CNC lathe adopts a stable inclined bed structure, which provides excellent rigidity and stability to ensure the processing of bearings.

Processing: Equipped with advanced CNC technology, it can achieve high-precision and high-efficiency metal processing to meet the manufacturing needs of complex parts.

Multi-axis control: Equipped with multi-axis control function, it can control multiple motion axes at the same time to realize three-dimensional processing of complex parts and improve processing flexibility.

Customized operation: A CNC system equipped with a plotting instrument allows operators to easily program and control through a simple interface, improving production efficiency.

Multi-functional processing: It is suitable for turning, milling, and other processing techniques. It has the characteristics of multi-productivity and multi-function, and can adapt to different processing needs.

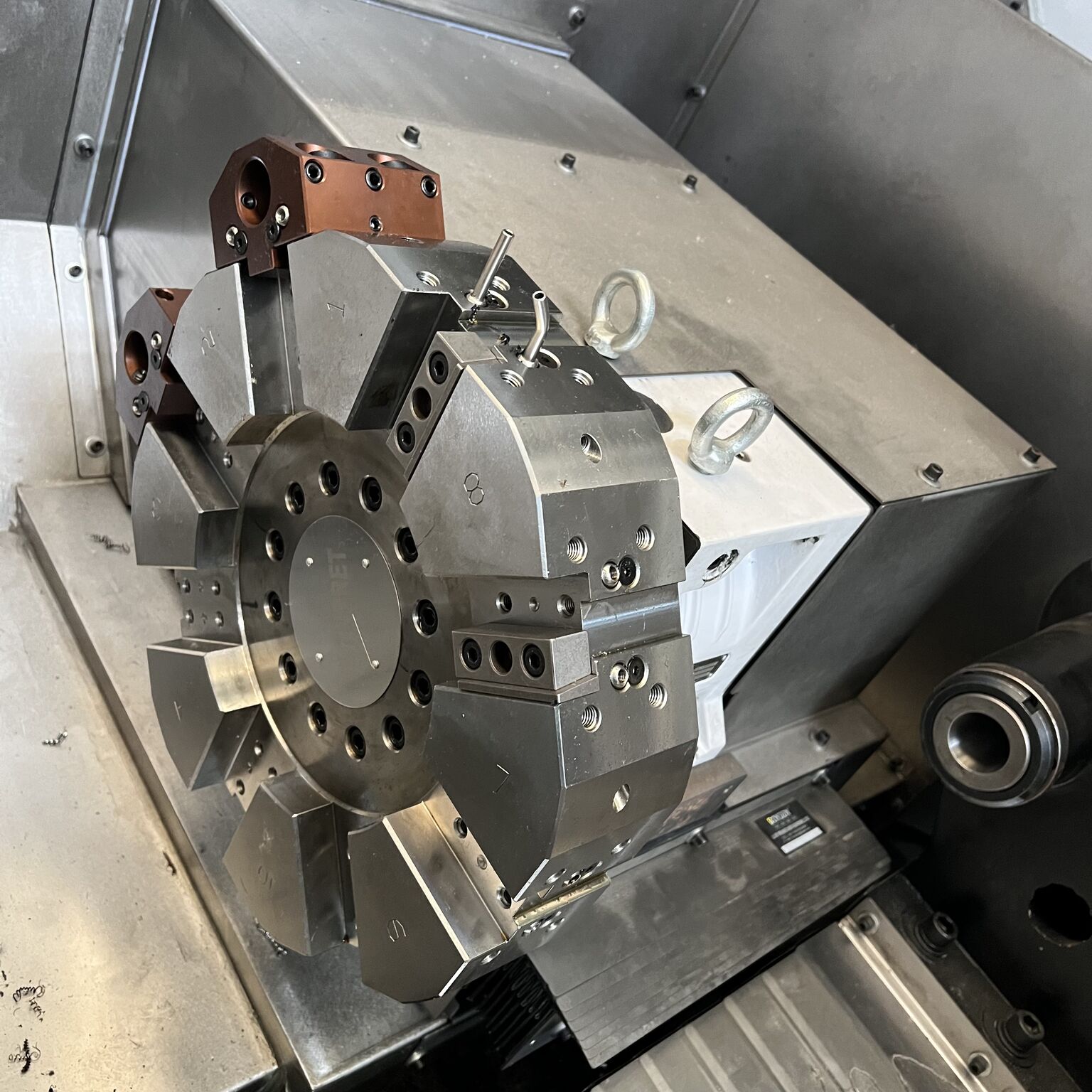

High-efficiency tool turret: Equipped with an automatic tool changing system and a high-efficiency tool turret to reduce high-efficiency switching time and improve production efficiency.

Product Parameter

| Item | Unit | FCK50 |

| Maximum slewing diameter on bed inner protection | mm | Φ560 |

| Turning diameter | mm | Φ500 |

| Turning length | mm | 500 |

| Spindle speed range | mm | 100-3000 |

| X-axis travel | mm | 280 |

| Z axis travel | mm | 550 |

| Machine frame dimensions | mm | 2250x1005 |

| Machine frame weight | kg | 2400 |

Product Application Industry

Aerospace industry: used to process complex parts such as aerospace engine parts and aircraft structural parts.

Automobile manufacturing: Suitable for the production of automobile engines, transmission systems and other parts, providing efficient and precise processing.

Mold manufacturing: used to manufacture various complex molds, including plastic molds, die-casting molds, etc.

Energy equipment: used to process parts of various energy equipment, such as generator sets, wind power equipment, etc.

Medical devices: Suitable for the production of medical device parts to ensure product quality and accuracy requirements.

General machinery manufacturing: It can extensively evaluate the manufacturing of general machinery parts and provide efficient and precise processing services.