PRODUCT

CNC lathes often provide high-precision machining, ensuring that workpieces meet design requirements. CNC lathes can control multiple axes at the same time to achieve complex workpiece processing. CNC lathes can automatically complete the processing process, reduce manual intervention, and improve production efficiency.

Features

Strong structural rigidity: The uniquely designed inclined bed structure provides excellent rigidity and stability, ensuring high-speed and high-precision processing.

High efficiency: Equipped with advanced CNC system to realize automated processing, improve production efficiency and reduce human errors.

Multi-functional processing: Integrated multi-axis control and multi-turret design can realize a variety of complex process processing, such as turning, milling, drilling, etc., to meet the processing needs of different workpieces.

Easy to operate: User-friendly CNC interface simplifies the operating process, reduces personnel training costs, and improves work efficiency.

High precision: The use of high-precision guide rails and screw rods, coupled with advanced servo control systems, ensures that the workpiece processing accuracy reaches the highest level.

Stable and reliable: Using high-quality mechanical and electronic components to ensure long-term stable operation of the equipment and reduce maintenance costs.

Product Parameter

| Item | Unit | FCK46 |

| Maximum slewing diameter on bed inner protection | mm | ∅490 |

| Turning length | mm | ∅300 |

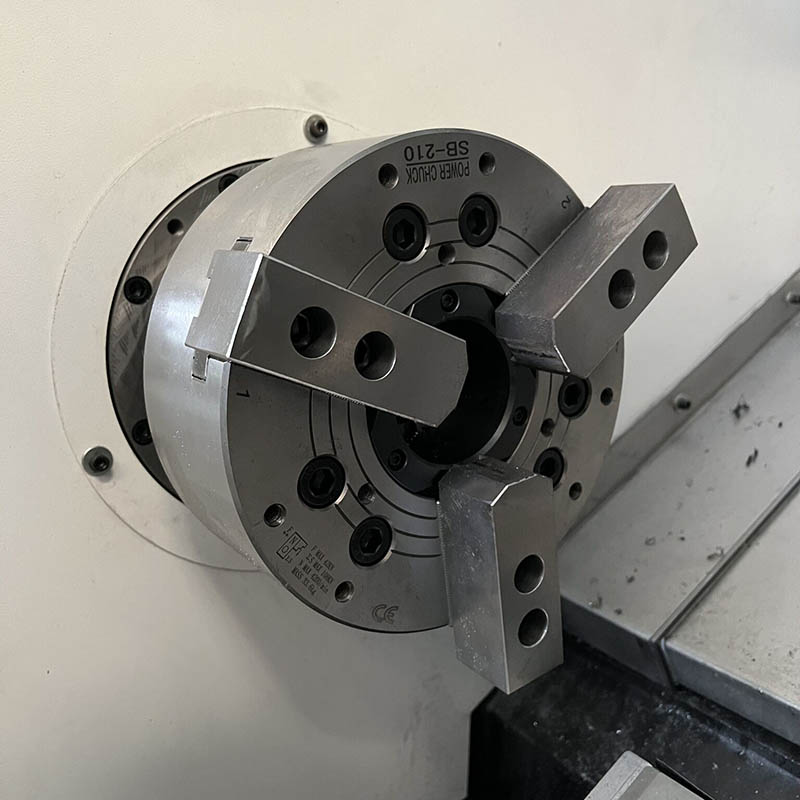

| Recommended standard turning diameter | mm | ∅210 |

| Cutting diameter | mm | Φ320 |

| Cutting length | mm | 400 |

| Maximum passing bar diameter | mm | Φ50 |

| X-axis travel | mm | 200 |

| Z-axis travel | mm | 450 |

| Overall size(L*W*H) | mm | 2400x1700x750 |

| Net weight | kg | 3050 |

Product Application Industry

Precision parts processing: Slant bed CNC lathe is suitable for processing parts that require extremely high precision, such as aerospace, automobile manufacturing and other fields.

Mold manufacturing: Slant bed CNC lathe can complete the processing of complex molds and ensure the accuracy and surface quality of the molds.

Mass production: Efficient automated processing makes it very suitable for mass production, improving production efficiency and product quality.

Shipbuilding: Slant bed CNC lathe is used to process large components and structural parts, ensuring accuracy and consistency in shipbuilding.

Medical device manufacturing: The processing requirements for precision medical devices are high, and inclined bed CNC lathes can meet these needs.

New material processing: Slant bed CNC lathe is suitable for high-precision and high-efficiency processing of new materials, alloys, etc.