PRODUCT

The inclined bed CNC lathe adopts an inclined bed structure, which provides higher rigidity and stability, ensuring high-precision processing, and is suitable for processing workpieces that require higher precision. Suitable for high-precision processing of precision parts, such as aerospace, automobile manufacturing and other fields.

Features

Strong Structural Rigidity: The slant bed CNC lathe adopts a slant bed structure, providing higher rigidity and stability to ensure high-precision processing, suitable for workpieces with high precision requirements.

Efficient CNC Operation: Equipped with advanced CNC systems, it can complete complex machining tasks through simple programming, significantly improving production efficiency and reducing operational complexity.

Multi-Axis Linkage: With multi-axis linkage capabilities, it can simultaneously control the movement of multiple axes, enabling complex surface machining and multi-process machining to meet diverse processing needs.

High Automation Level: Equipped with automatic tool change systems, automatic measurement systems, and other automated devices, it reduces manual intervention, enhances production efficiency, and reduces labor intensity.

Multifunctional Tool Turret: Equipped with a multifunctional tool turret, it can perform various machining operations such as turning, milling, drilling, meeting different process requirements.

Precision Positioning System: High-precision positioning system ensures workpiece accuracy, suitable for the machining of workpieces with strict size and shape requirements.

Energy-Saving and Environmental Protection: Utilizing advanced drive technology and energy-saving design to reduce energy consumption, meeting environmental requirements.

Product Parameter

| Item | Unit | FCK46 |

| Maximum slewing diameter on bed inner protection | mm | ∅490 |

| Turning length | mm | ∅300 |

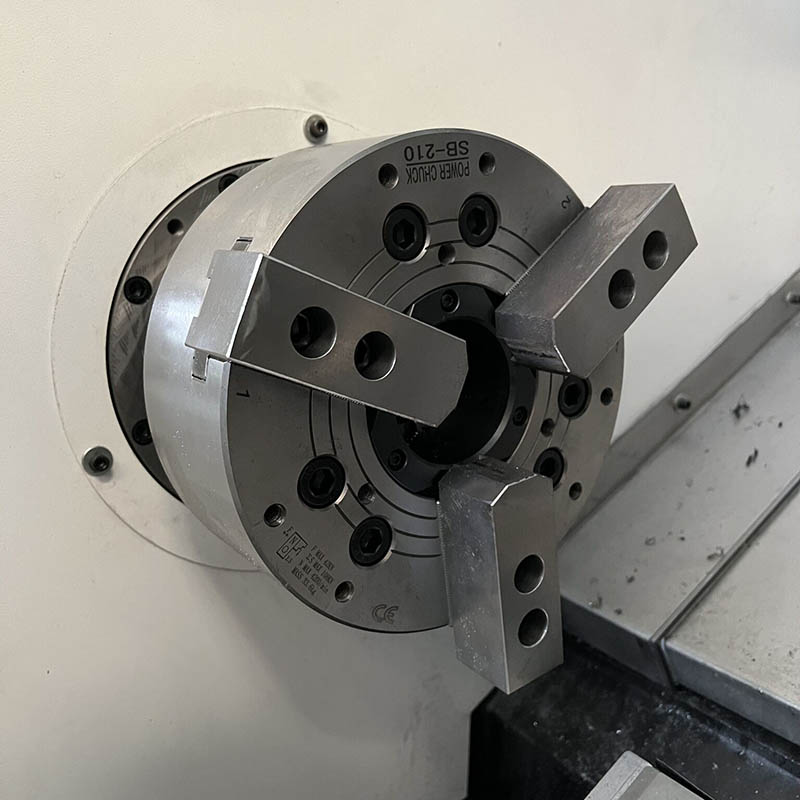

| Recommended standard turning diameter | mm | ∅210 |

| Cutting diameter | mm | Φ320 |

| Cutting length | mm | 400 |

| Maximum passing bar diameter | mm | Φ50 |

| X-axis travel | mm | 200 |

| Z-axis travel | mm | 450 |

| Overall size(L*W*H) | mm | 2400x1700x750 |

| Net weight | kg | 3050 |

Product Application Industry

Mold Manufacturing: CNC lathes are capable of completing complex shaping processes for molds, meeting the demands of the mold manufacturing industry.

Mass Production: Efficient CNC operations and automation equipment make them suitable for mass production, enhancing production efficiency.

Rail and Rail Transportation Component Manufacturing: CNC turning machines are suitable for manufacturing high-precision components in the railway and rail transportation sectors.

Medical Equipment Manufacturing: They exhibit good adaptability for the high-precision and high-quality processing of components in the medical equipment manufacturing industry.

Shipbuilding: CNC turning machines are applicable to the machining of large components and hull structures in shipbuilding.

Electronic Component Manufacturing: CNC lathes are used for processing the shells and structures of electronic components, ensuring high precision and surface quality.