PRODUCT

Flat Bed CNC Lathe CK6150X2000

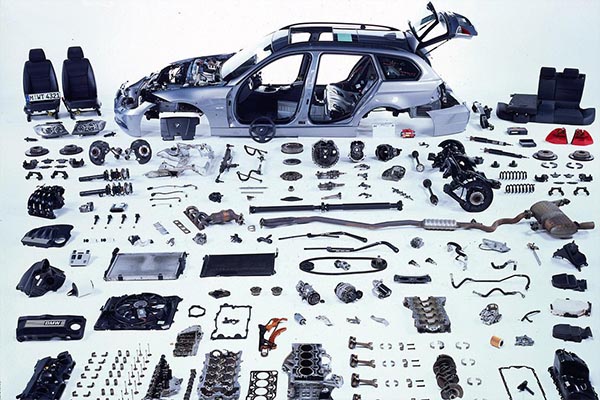

CK6150X2000 CNC lathes are widely used in the automotive industry. They can process various complex auto parts and accessories, improve production efficiency and product quality, and have made important contributions to the development of the automotive industry.

CK6150X2000 Flat Bed CNC Lathe bed adopts integral casting process, which has the advantages of high strength, high rigidity, high precision, excellent stability and saving processing time. Flat Bed CNC Lathe is a high-performance, high-precision CNC machining equipment.

CK6150 Flat Bed CNC Lathe bed adopts one-piece casting process, which has the following advantages:

1. High strength and high rigidity: The CNC automatic lathe bed is made of cast iron material, the overall structure is stable, and it has good anti-deformation and anti-vibration capabilities to ensure high-precision and high-rigidity processing.

2. High precision: The cnc automatic lathe adopts an integrated casting process, which can reduce the machining interface of the bed, thus avoiding the loosening of the interface. The impact of deformation and other issues on accuracy.

3. Excellent stability: The integrally cast bed of the horizontal cnc lathe machine has uniform material density and internal structure, which can effectively reduce errors caused by material deformation, thereby improving the stability and reliability of the CNC lathe.

4. Save processing time: The horizontal cnc lathe machine bed adopts an integrated casting process, which can reduce the processing seats of the machine tool, shorten the production cycle, and reduce the production cost.

Product Application Industry

CK6150 3 axis cnc lathe is widely used in the automotive industry, mainly used to process various auto parts and accessories, such as:

1. Crankshaft and connecting rod: 3 axis cnc lathe can accurately process engine parts such as crankshaft and connecting rod to ensure its precision and durability.

2. Gears and bearings: 3 axis cnc lathe can process various gears and bearings to ensure its high precision and low noise performance.

Video

Product Parameter

| Item | Unit | CK6150X2000 |

| Max swing over bed | mm | Φ500 |

| Maximum swing over slide | mm | Φ290 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 2000 |

| X/Z axis maximum stroke | mm | 2000 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |