PRODUCT

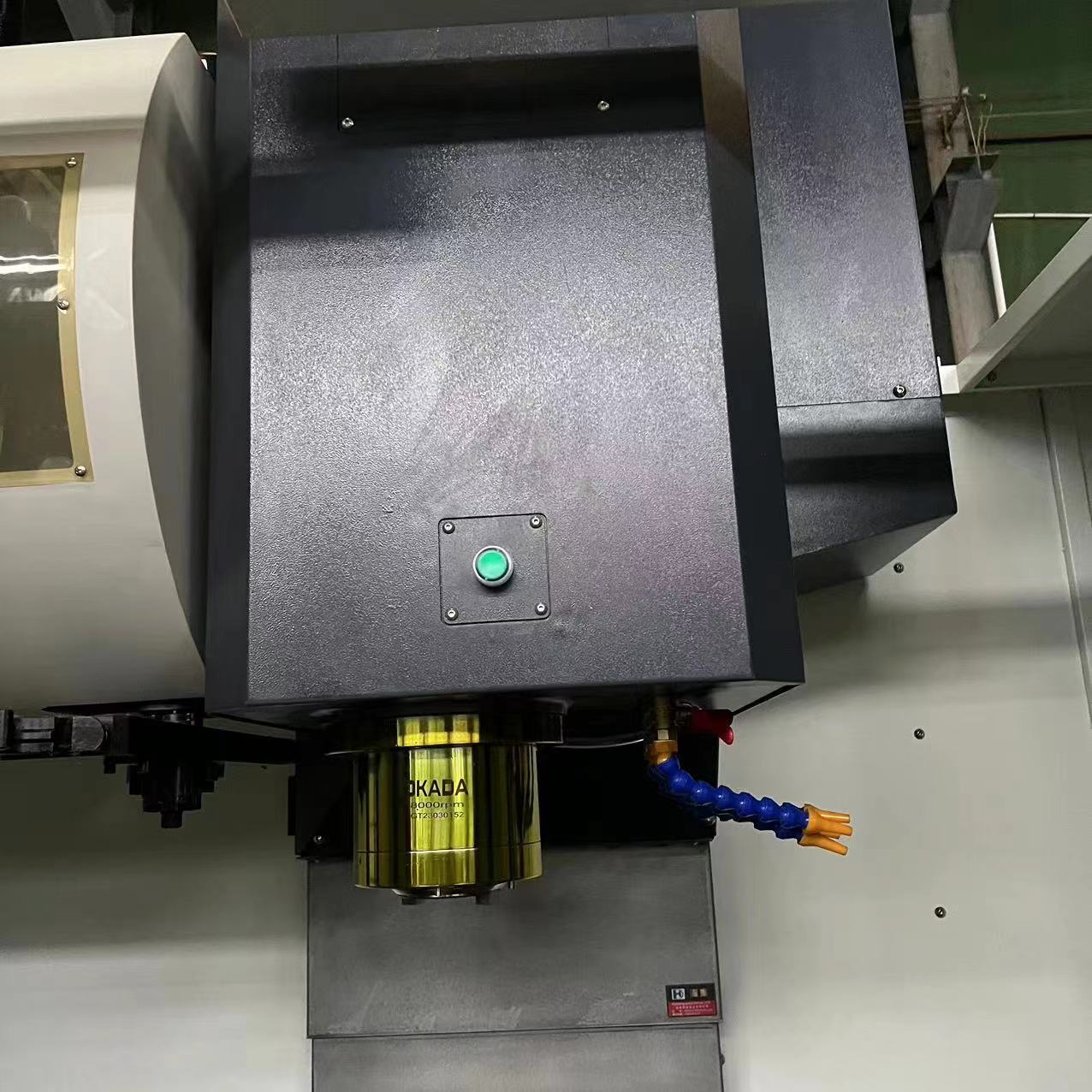

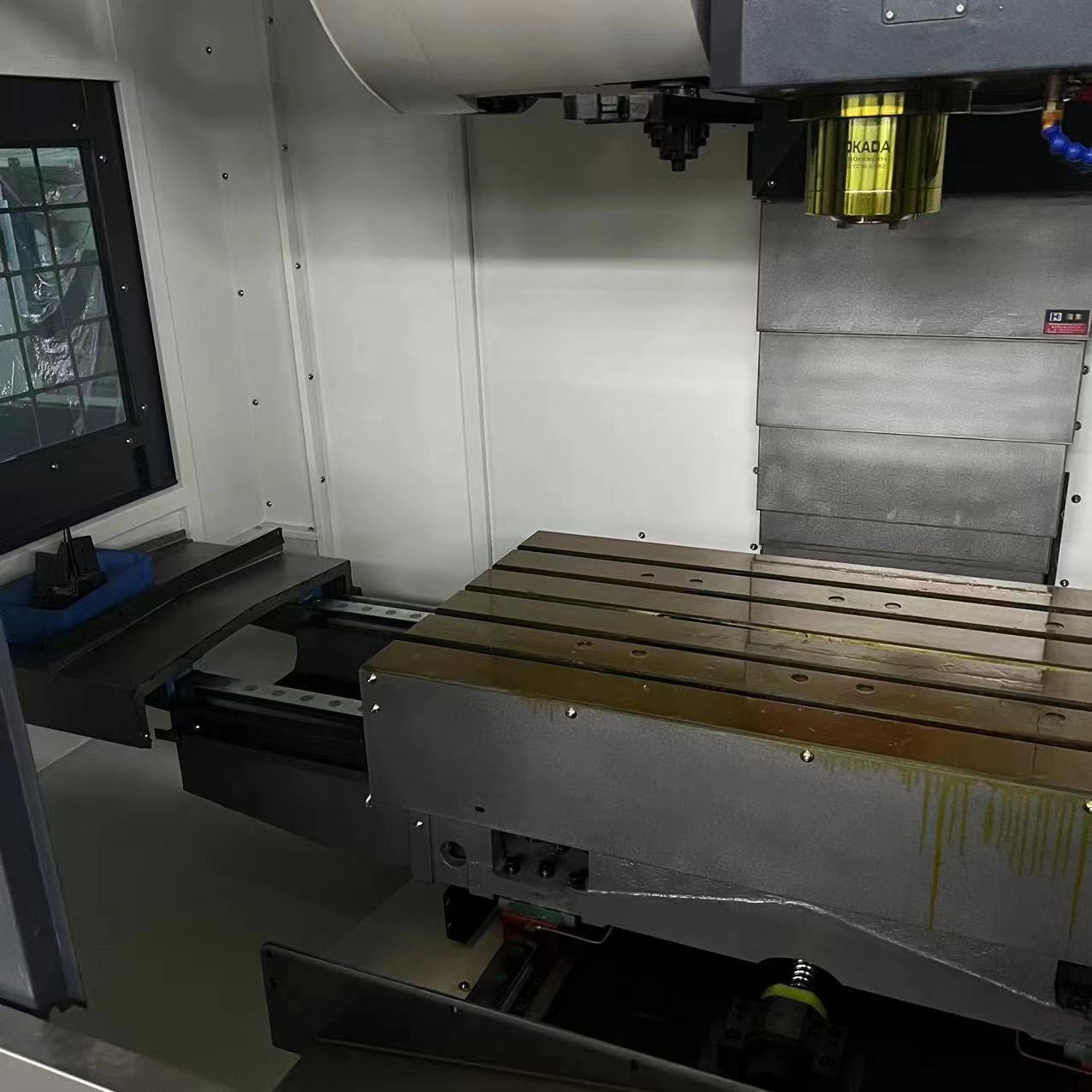

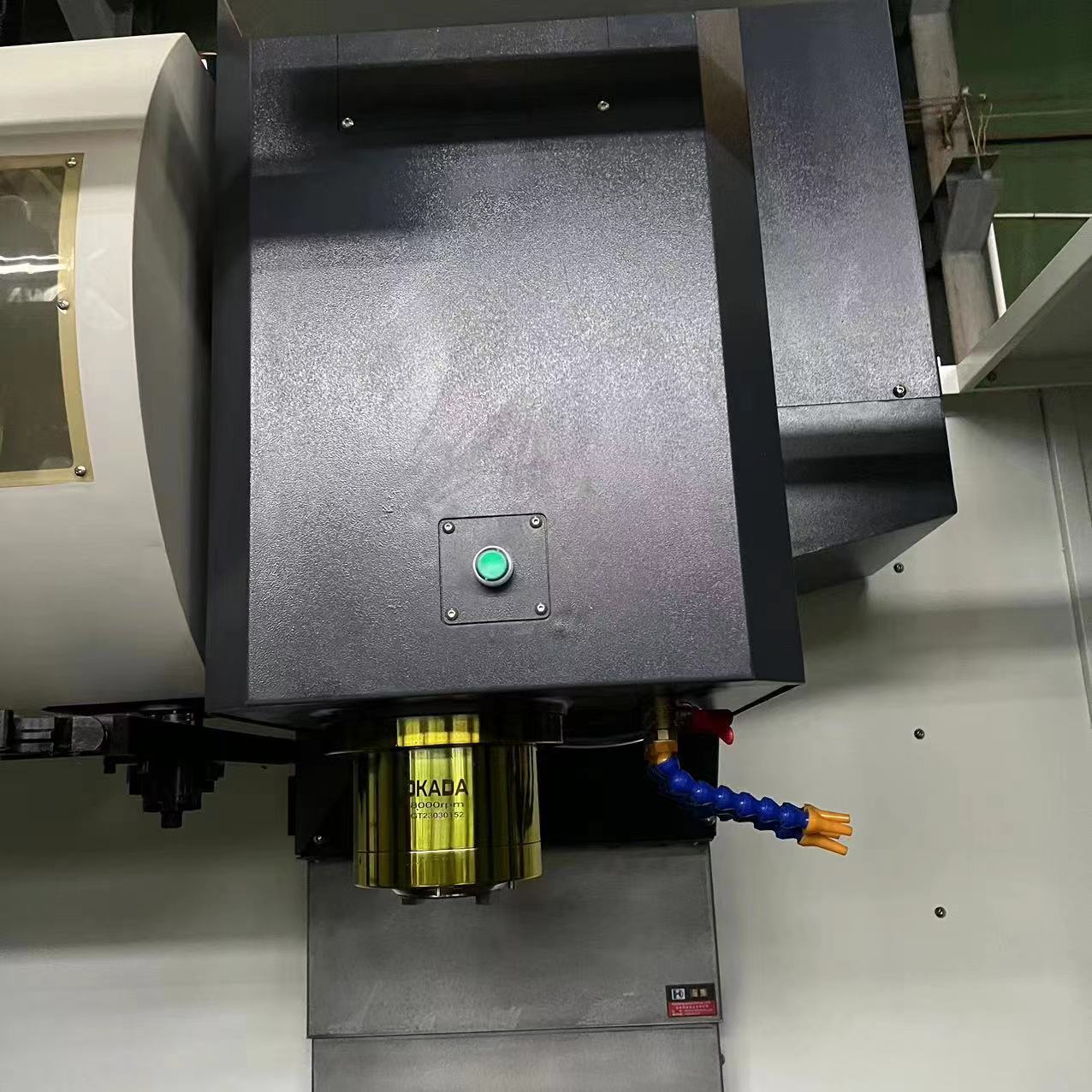

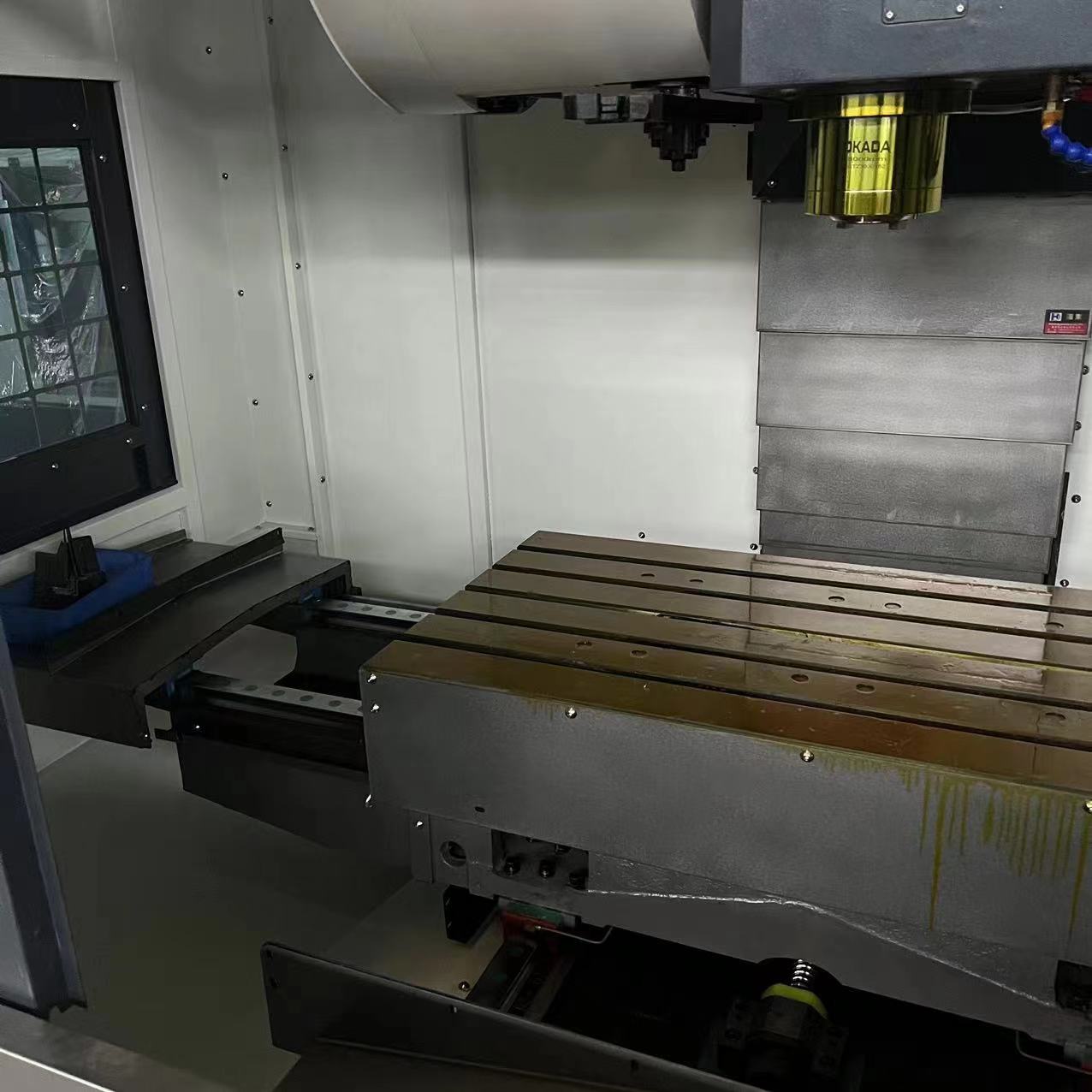

cnc machine center VMC1160

Brand - ALLESCNC

Model - VMC1160

Dimensions - 3200x2450x2650mm

Price - $31,700(Standard Edition)/$33,200(Pro Edition)

Availability - 400 pieces of inventory available for sale every month

Certification - Meeting CE Standards in Terms of Quality & Safety

Payment Method - T/T/ Credit Cards

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

Product Details:

VMC1160 is usually equipped with a high-speed spindle to support high-speed cutting and improve processing efficiency.

The spindle uses high-precision bearings to ensure stability during high-speed rotation and reduce thermal deformation.

High-precision ball screws and linear guides are used to ensure the movement accuracy of each axis.

The high-resolution encoder of the CNC system provides accurate displacement feedback, making the processing accuracy higher.

Equipped with an automatic tool changer, it improves the degree of automation of processing, reduces manual intervention time, and improves production efficiency.

Vertical Machining Center VMC1160 Features

VMC1160 is equipped with a modern CNC system with a friendly operating interface, easy to program and use.

Since it supports a variety of processing technologies (such as milling, drilling, tapping, etc.), VMC1160 can be applied to the processing of a variety of different materials.

With strong reliability and stability, after optimized design and rigorous testing, VMC1160 can maintain stability during long-term continuous operation and reduce downtime.

Key Advantages:

Multi-surface machining in one setup, reducing clamping errors

Cradle structure allows machining of complex 3D surfaces and irregular shapes

Higher precision, stability, and surface quality

Shorter machining cycles and improved productivity

Widely used in aerospace, automotive, medical equipment, mold manufacturing, and other high-end industries

The 5-Axis Vertical Machining Center represents the cutting-edge level of modern CNC technology and is the ideal solution for manufacturing high-precision, complex parts.

Product application industry

VMC1160 is commonly used in mold processing industries such as plastic molds and stamping molds. Its high precision and high-speed cutting capabilities make it very suitable for precision processing of molds.

In the field of automobile manufacturing, VMC1160 can process engine parts, gearbox housings, automobile chassis and other complex structural parts.

In the field of aerospace, the aerospace industry requires extremely high precision and quality control. VMC1160 is suitable for the processing of aerospace parts with its high precision and stability.

VMC1160 is widely used in the processing of mechanical equipment parts, such as racks, gears, valve bodies, etc.

Video

Product Parameter

| Item | Unit | VMC1160 |

| X axis Travel | mm | 1100 |

| Y axis Travel | mm | 600 |

| Z axis Travel | mm | 600 |

| Spindle nose to worktable | mm | 120-720 |

| Spindle center to coumn face | mm | 670 |

| Spindle speed |

rmp |

8000 |

| Max. tool weight | kg | 8 |

| Floor area and height | mm |

3000*2500*2500 |

| Machine weight | kg | 6500 |

Axis Movements:

X-Axis: Left and right movement

Y-Axis: Forward and backward movement

Z-Axis: Up and down movement

A/B-Axis: Rotation around the X-axis or Y-axis

C-Axis: Rotation around the Z-axis