PRODUCT

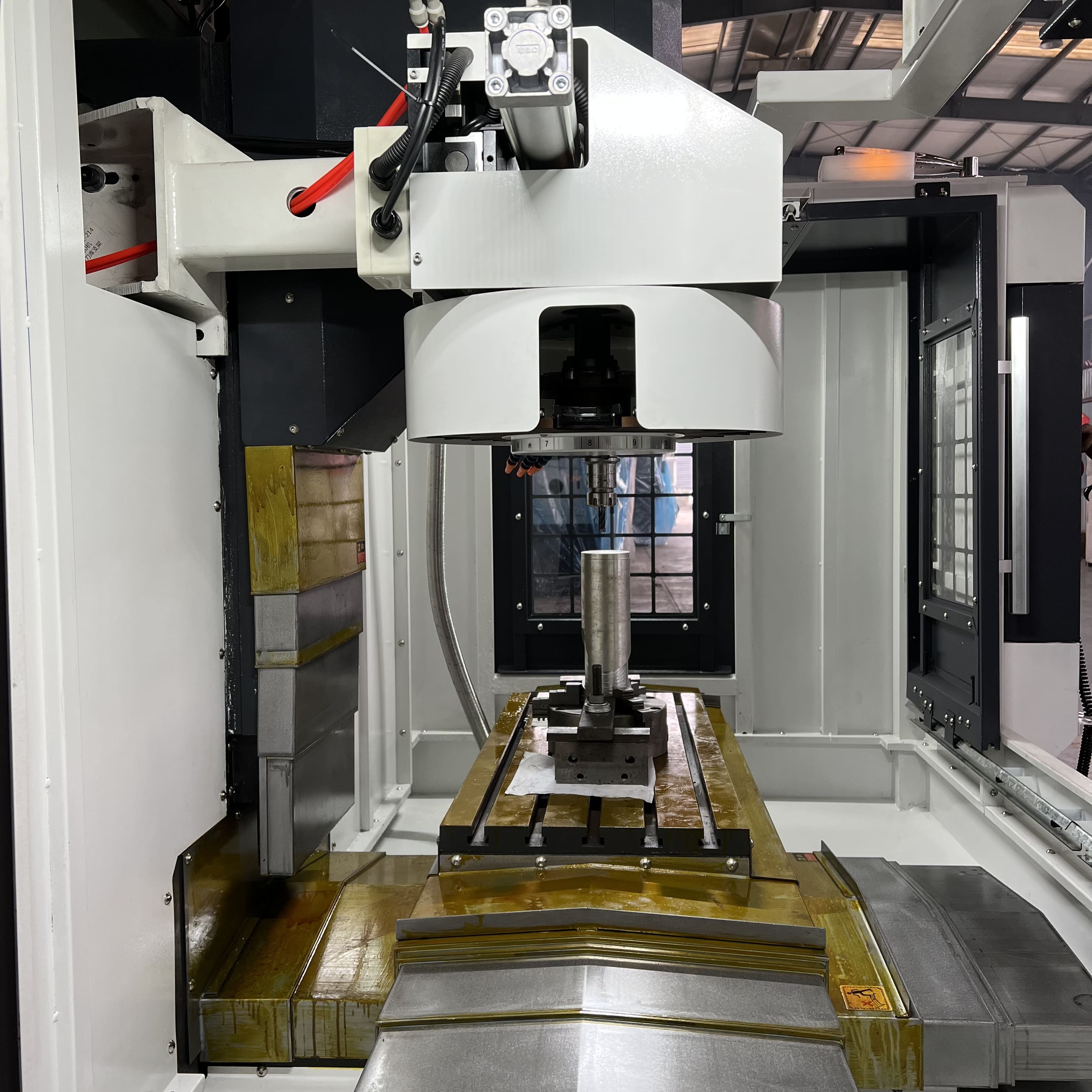

vmc650 Vertical machining center

VMC650 is usually equipped with an automatic tool changing system with fast tool changing speed, which reduces the time of manual tool changing and improves machining efficiency.The machine supports simultaneous movement of three axes and can complete complex geometric shapes.

VMC650 is usually equipped with a high-speed, high-precision spindle with a speed of up to 8000-12000 rpm, capable of precision cutting.

The X, Y, and Z axes of the machining center have high positioning accuracy, ensuring the machining accuracy of the workpiece.

VMC650 is usually equipped with an automatic tool changing system with fast tool changing speed, which reduces the time of manual tool changing and improves machining efficiency.

The machine supports simultaneous movement of three axes and can complete complex geometric shapes.

Vertical Machining Center VMC650 Features

VMC650 adopts a cast iron one-piece bed structure with good vibration resistance and stability, and can withstand high-intensity cutting forces.

Ball screws and linear guides are usually used to provide high rigidity and durability, making it suitable for long-term continuous processing.

It is suitable for milling, drilling, tapping and other processes, and can process workpieces of different materials, including steel, aluminum, plastic, etc.

Equipped with CNC systems (such as FANUC, Mitsubishi, etc.), it is easy to operate and can perform complex surface processing tasks.

Product application industry

VMC650 is widely used in many industries and fields due to its high precision, high efficiency and versatility.

1. Used to manufacture injection molds for automotive parts, home appliances, etc. to ensure the high precision and complex geometry of the molds.

Suitable for manufacturing metal die-casting molds to meet the requirements of high strength and high wear resistance.

Used to produce cold stamping molds such as electronic product housings and home appliance parts.

2. Automobile industry

Engine parts: Processing high-precision engine parts such as cylinder heads, crankshafts, connecting rods, etc.

Transmission system: Manufacturing gearbox gears, differential parts, etc. to ensure the efficient operation of the transmission system.

Body structure parts: Processing doors, frames and other structural parts to meet the requirements of lightweight and high strength of automobiles.

Video

Product Parameter

| Item | Unit | VMC650 |

| X axis Travel | mm | 650 |

| Y axis Travel | mm | 500 |

| Z axis Travel | mm | 500 |

| Distance from spindle nose to table | mm | 100-600 |

| Distance from spindle center to column | mm | 550 |

| Worktable size | mm | 800X500 |

| Max. loading capacity | kg | 400 |

| T-slot | mm |

5X18X90 |

| Speed | rpm | 800 |