PRODUCT

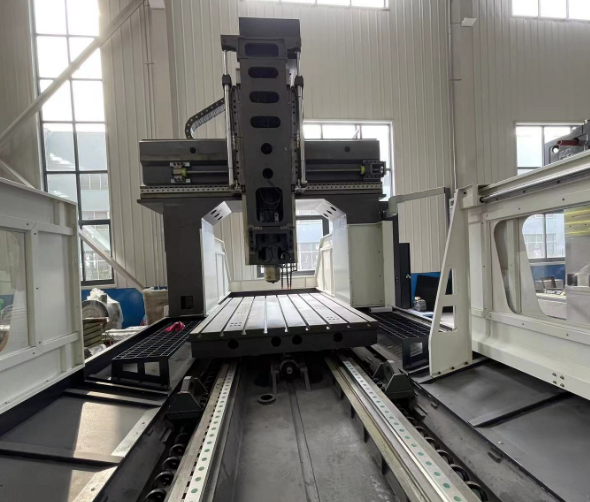

Gantry type cnc milling machine ALGMC2016L

Gantry type CNC milling machine ALGMC2016L is a large gantry CNC milling machine. GMC usually stands for: Gantry Milling Center, 2016L represents the working stroke of approximately X axis 2000mm × Y axis 1600mm

Features of Gantry type CNC milling machine

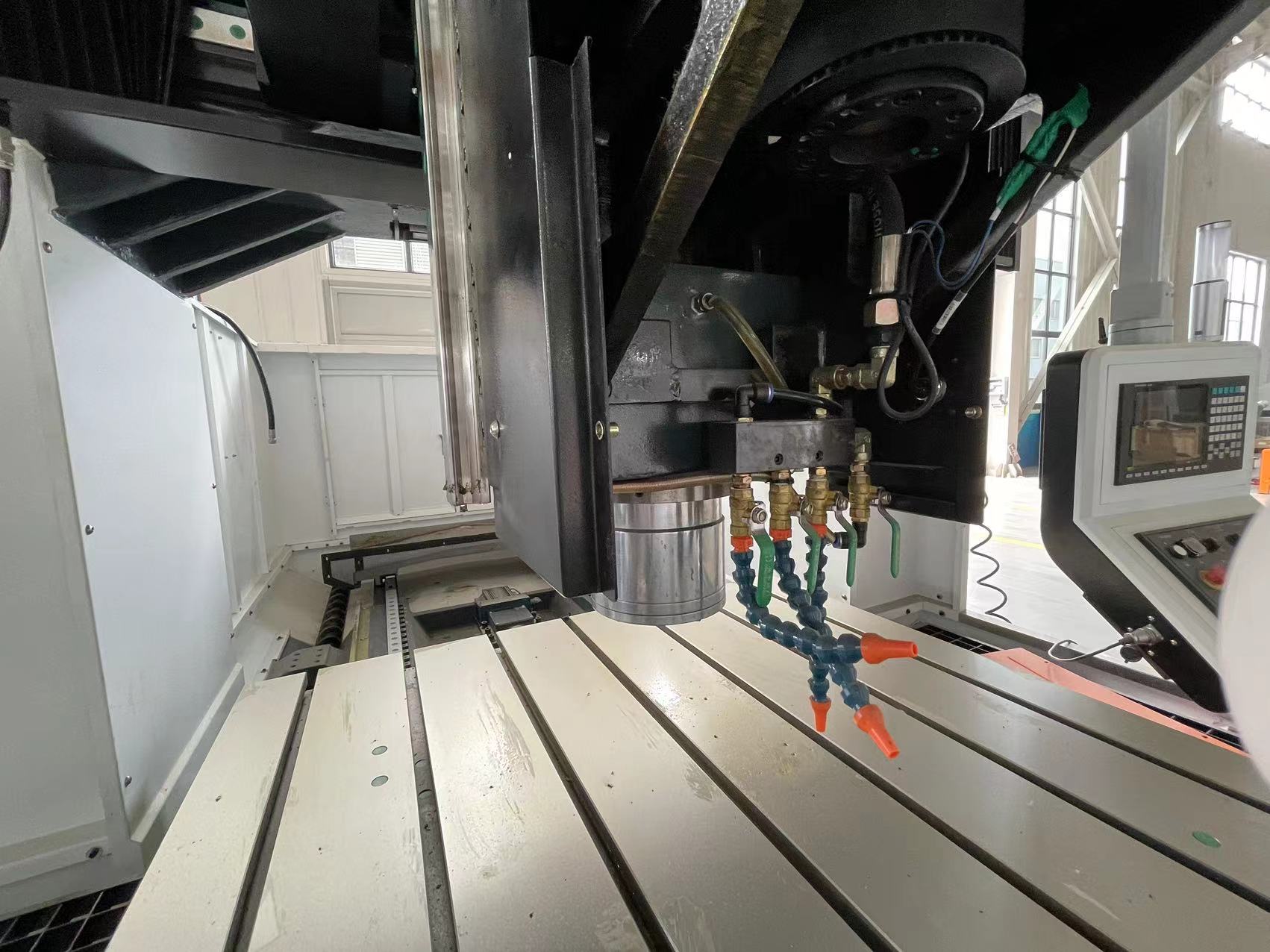

The ALGMC2016L Gantry-Type CNC Milling Machine features a stable and reliable gantry frame with a fixed crossbeam and a movable worktable, offering exceptional vibration resistance and structural stability, ensuring long-term, high-precision machining. Large castings are fully annealed to eliminate internal stress and effectively prevent deformation.

Its large machining travel of 2000mm in the X-axis and 1600mm in the Y-axis (customizable up to 800mm or greater in the Z-axis) makes it suitable for oversized molds and parts.

Product application industry

The Gantry type CNC milling machine ALGMC1613 is widely used in the following industries:

Mold manufacturing: injection molds, die-casting molds, stamping molds, etc.

Automotive manufacturing: engine housings, frame molds, chassis components

Aerospace: aluminum alloy structural parts, titanium alloy support components, complex and special-shaped parts

Rail transportation: vehicle frames, large connectors, welded components

Construction machinery: large machinery bases, flanges, sliders, and other structural parts

New energy equipment: wind turbine nacelle parts, hydropower equipment frames, etc.

Video

Product Parameter

| Item | Unit | ALGMC2016L |

| Working desk size | mm | 2200*1400 |

| Workbench bearing | kg | 4500 |

| T-slot width | mm | 9*18*144 |

| X-axis travel | mm | 2100 |

| Y-axis travel | mm | 1630 |

| Z axis travel | mm | 700 |

| Cutting feed speed range | m/min | 1-10 |

| Spindle end face to table distance | mm | 150-850 |

| Pull stud specification | P50T-1-MAS403(45°) |

| Host Dimensions | mm | 5700*2500*3100 |

| Host weight | T | 16.5 |