PRODUCT

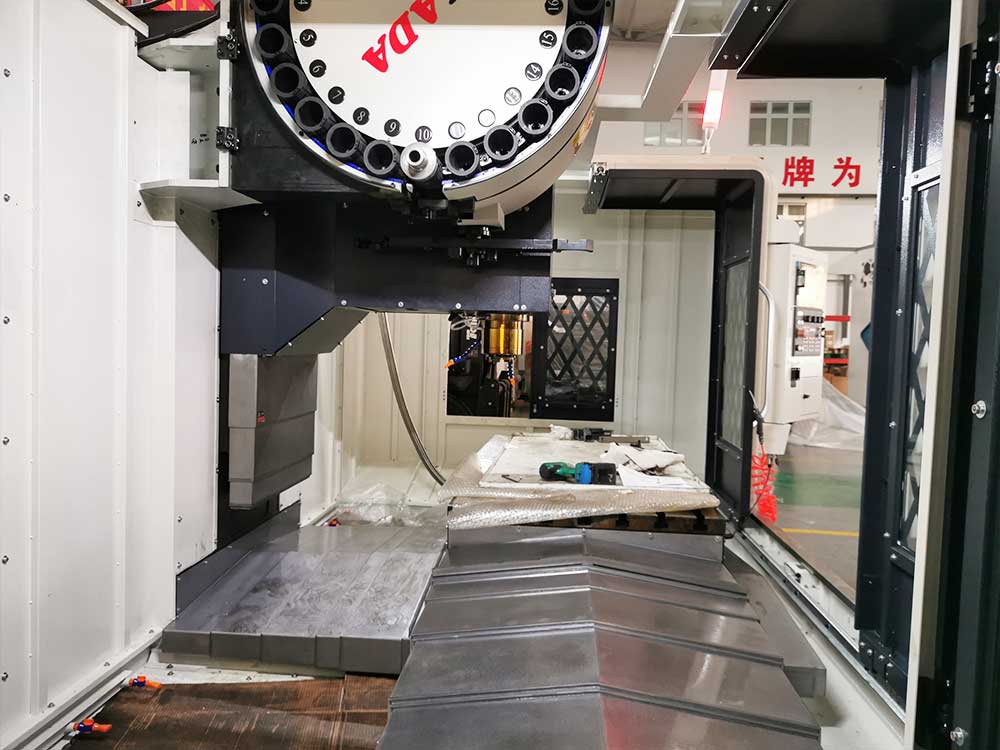

cnc vertical machining center VMC1580

VMC1580 is a large vertical machining center suitable for high-precision machining of a variety of complex parts and molds. Compared with medium-sized models such as VMC1160, VMC1580 has a larger worktable size and travel, suitable for machining large workpieces.

VMC1580 machine tools usually use an integrated high-strength cast iron bed to ensure the high rigidity and vibration resistance of the machine tool, which is suitable for heavy cutting conditions.

After finite element analysis and optimization design, the machine tool's anti-deformation ability is improved, ensuring the processing accuracy under heavy loads.

High-precision spindle system, equipped with a high-precision, high-speed spindle system, the common spindle speed is 6000-8000rpm, suitable for high-speed and heavy cutting operations.

The spindle usually uses an oil cooling system to effectively control thermal deformation and maintain the stability of the spindle.

Vertical Machining Center VMC1580 Features

All three axes are equipped with high-precision ball screws and linear guides to ensure high precision in every direction of movement.

High-resolution encoders provide accurate feedback for the CNC system to ensure the repeatability and processing accuracy of the machine tool.

Powerful cutting ability. Since the machine tool has a large power output, it is suitable for high-speed heavy cutting of hard materials.

The machine tool is usually equipped with an automatic tool changing system with a 24-32 tool magazine, which supports the rapid switching of various complex processes and further improves production efficiency.

Product application industry

VMC1580 is often used in the processing of large injection molds and stamping molds in the automotive and home appliance industries. Its large stroke and high precision are suitable for high-precision processing of various complex molds.

Parts in the aerospace industry, such as body structural parts and engine parts, require high-precision and complex geometric shapes. The large size and multi-axis linkage capabilities of VMC1580 can meet these needs.

In the field of automobile manufacturing, VMC1580 can be used to process large parts such as engine cylinders, gearbox housings, chassis structural parts, etc.

VMC1580 is widely used in the processing of large parts in the heavy machinery manufacturing industry, such as machine tool beds, gearboxes, pump housings, etc., which require large workpieces with high precision and high stability.

Video

Product Parameter

| Item | Unit | VMC1580 |

| X axis Travel | mm | 1500 |

| Y axis Travel | mm | 800 |

| Z axis Travel | mm | 700 |

| Distance from spindle nose to work surface | mm | 185-885 |

| Distance from spindle center to column | mm | 885 |

| Spindle speed |

rmp |

6000 |

| Maximum tool weight | kg | 15 |

| Floor area and height | mm |

3550*3100*2850 |

| Machine weight | kg | 12000 |