PRODUCT

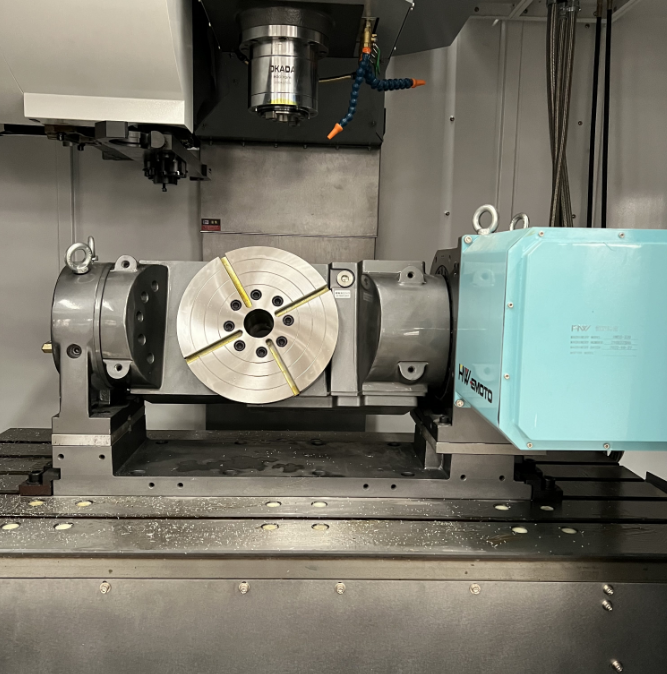

cnc vertical machining center vmc1370

The wide application of VMC1370 in the manufacturing industry makes it the preferred equipment for processing many medium to large workpieces, especially in industries that require precision processing and efficient production. It has irreplaceable advantages and is widely used in a variety of manufacturing industries, especially suitable for processing medium and large parts.

VMC1370 is usually made of high-quality cast iron, which makes the machine tool have high vibration resistance and rigidity, and can maintain stability during heavy-load processing.

The larger worktable size is suitable for processing medium to large workpieces.

Equipped with high-precision linear rails or hard rails to ensure processing accuracy, suitable for high-precision parts processing.

Usually the spindle speed can reach 8000 to 10000 rpm), to meet the needs of high-speed cutting.

Usually equipped with FANUC, Siemens or other advanced CNC systems, easy to operate, powerful functions, and can realize multi-axis linkage processing

Vertical Machining Center VMC1370 Features

VMC1370 is suitable for processing various materials, such as aluminum alloy, steel, stainless steel, etc., and is especially suitable for precision processing of complex parts.

Automatic tool change and high-speed spindle design can reduce downtime and improve production efficiency.

Suitable for processing tasks requiring high precision, and can ensure the stability of long-term processing.

Modern design makes the machine maintenance easier and saves maintenance time.

Users can configure different spindles, CNC systems, tool magazines, etc. according to their needs, with high flexibility and can be tailored according to specific needs.

Product application industry

VMC1370 is suitable for precision machining of various plastic molds and injection molds, especially medium and large molds.

Machining of automobile parts such as engine housings, gearbox housings and other medium and large structural parts.

Used for machining complex and high-precision parts such as aero-engine parts and aircraft parts.

Machining of various mechanical equipment parts such as machine tool parts, industrial equipment brackets, etc.

Used for machining precision parts and electronic product housings.

Machining of wind power equipment parts, solar power equipment parts, electric vehicle parts, etc.

Video

Product Parameter

| Item | Unit | VMC1370 |

| X axis Travel | mm | 1300 |

| Y axis Travel | mm | 750 |

| Z axis Travel | mm | 700 |

| Spindle nose to worktable | mm | 120-720 |

| Spindle center to coumn face | mm | 670 |

| Spindle speed |

rmp |

8000 |

| Max. tool weight | kg | 8 |

| Floor area and height | mm |

3050*2250*2400 |

| Machine weight | kg | 7500 |