PRODUCT

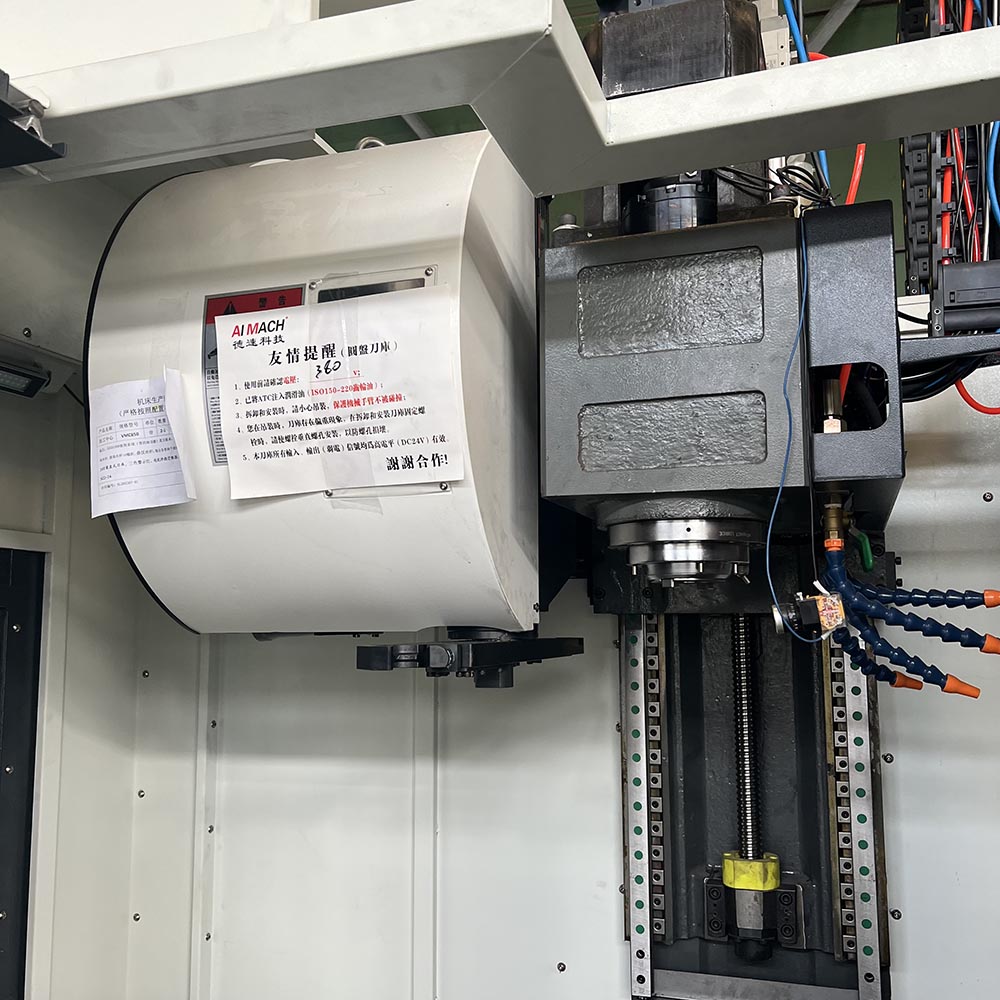

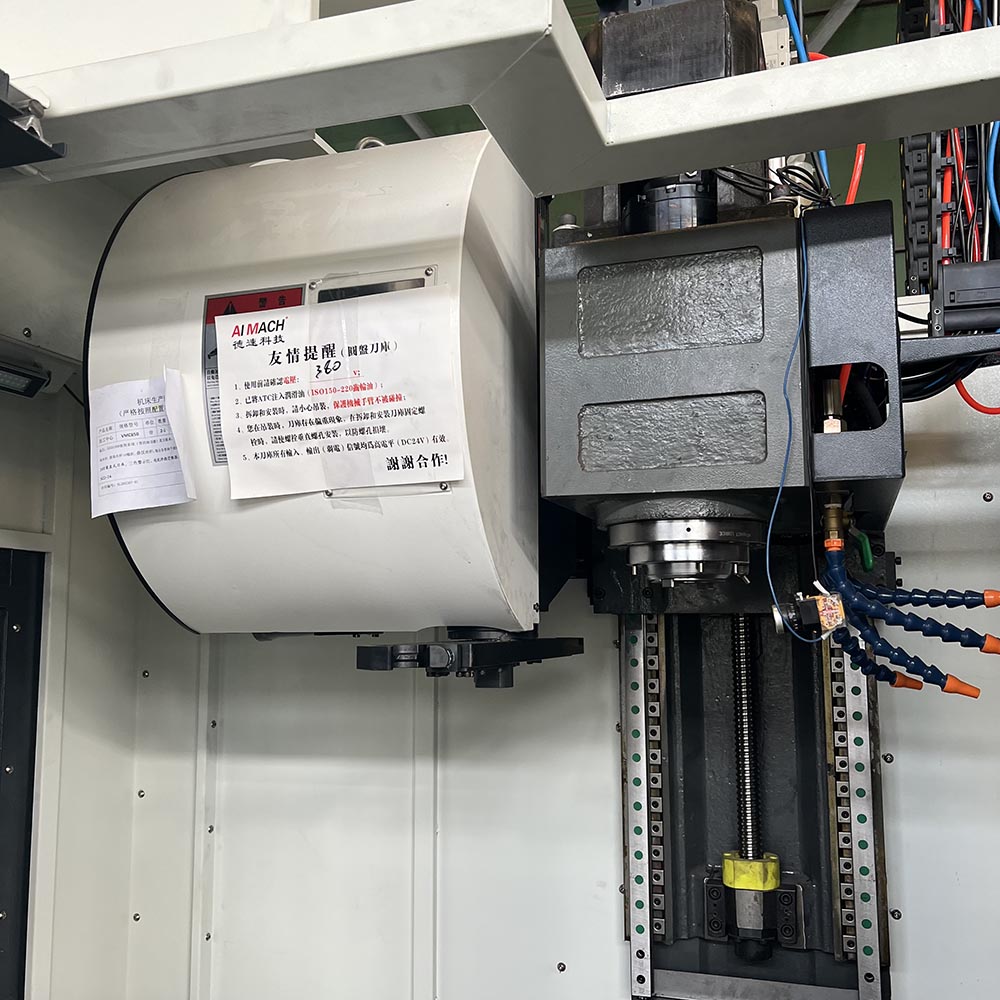

Vertical machining center vmc850

With its excellent performance and wide applicability, VMC850 has become an important equipment for major manufacturing companies to improve production capacity and product quality.Support multiple processing modes and complex processes, adapt to the processing needs of different products and parts, and have good adaptability.

VMC850 Through high-rigidity structure and advanced CNC system, high-precision processing is achieved to meet high-demand manufacturing needs.

High-speed spindle and automation function greatly improve the processing speed, shorten the production cycle and reduce production costs

Support multiple processing modes and complex processes, adapt to the processing needs of different products and parts, and have good adaptability.

Vertical Machining Center VMC850 Features

Friendly user interface and intelligent control system simplify the operation process, reduce the difficulty of operation, and improve the work efficiency of operators.

The use of high-quality components and advanced manufacturing technology ensures the long-term stable operation of the machine tool and reduces maintenance and downtime.

Product application industry

VMC850 is used to process high-precision and high-complexity parts such as aircraft engine parts and structural parts to meet strict quality requirements.

Suitable for processing key parts such as automobile engine cylinders and gearboxes to improve product consistency and reliability.

Used for precision processing of plastic molds, die-casting molds, etc. to ensure the accuracy and service life of the molds.

Processing medical equipment parts such as surgical instruments and medical equipment housings to meet high precision and hygiene standards.

Used for processing parts such as housings and radiators of electronic products to meet small batch and diversified production needs.

Video

Product Parameter

| Item | Unit | VMC850 |

| X axis Travel | mm | 800 |

| Y axis Travel | mm | 500 |

| Z axis Travel | mm | 500 |

| Spindle nose to worktable | mm | 150-650 |

| Spindle center to coumn face | mm | 572 |

| Spindle speed |

rmp |

1000 |

| Max. tool weight | kg | 8 |

| Floor area and height | mm |

2550*2250*2400 |

| Machine weight | kg | 5000 |