PRODUCT

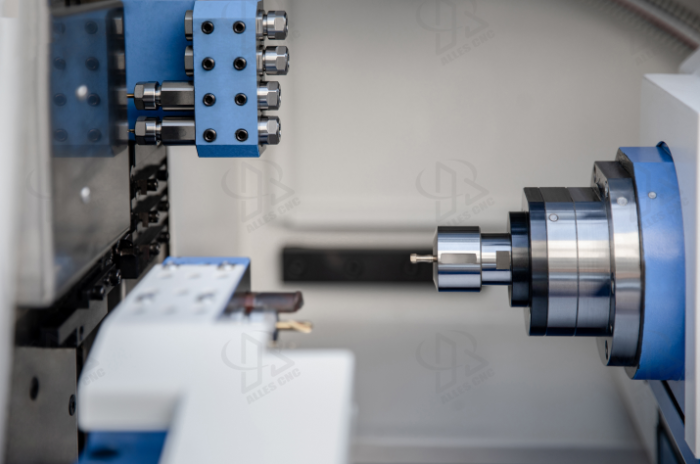

ALSL325 Swiss Lathe

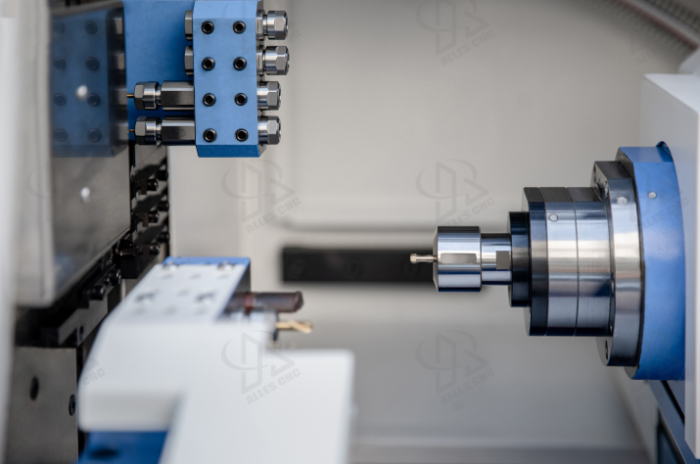

Swiss lathes usually adopt a dual guide rail design. The spindle and tailstock move on independent guide rails, which improves the stability and accuracy of processing.

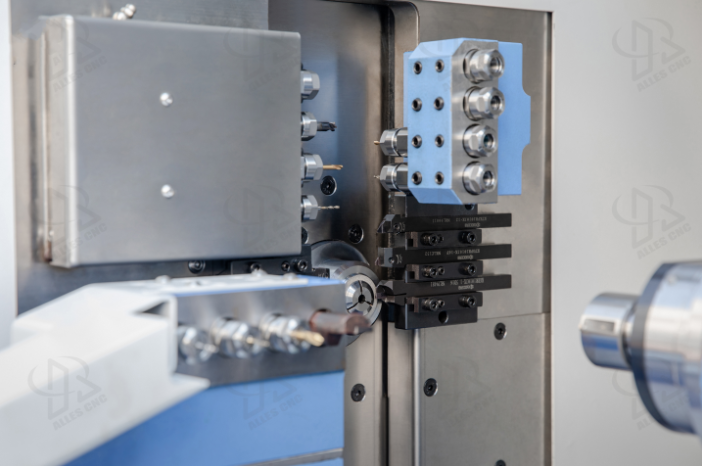

Equipped with advanced automatic feeding, clamping and tool changing systems, it can achieve unattended and efficient production, significantly improving production efficiency and consistency.

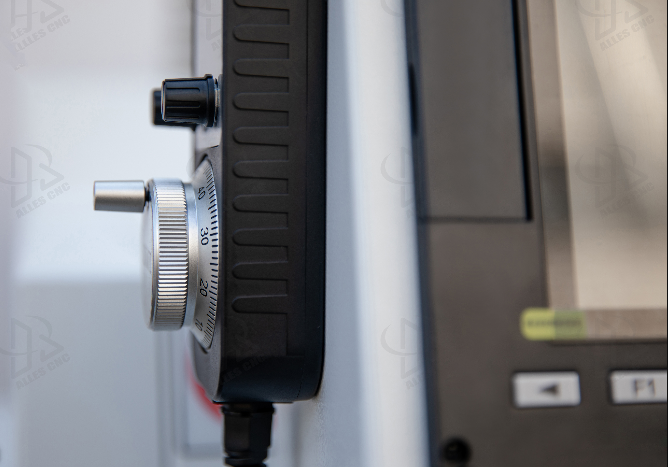

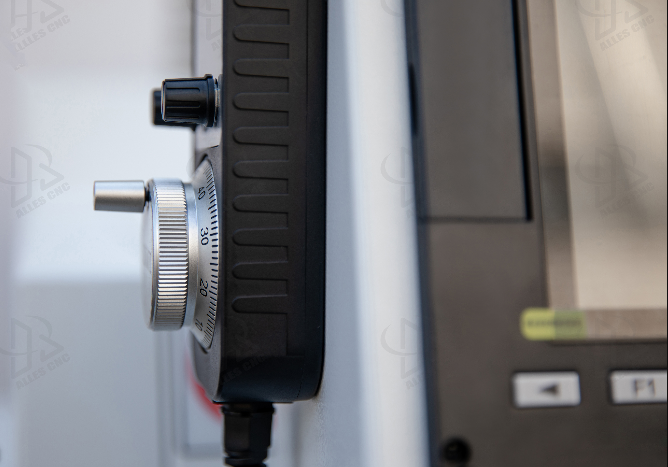

Swiss lathes have a high rigidity and low vibration structural design, coupled with an advanced CNC system, which enables Swiss lathes to perform extremely high-precision processing and meet micron-level tolerance requirements.

Usually equipped with multiple tool magazines, they support automatic switching of multiple processes, such as turning, drilling, milling, etc., reducing the number of workpiece replacements and improving processing efficiency.

The overall design of Swiss lathes is compact and occupies a small area, making them suitable for use in workshops with limited space, while also being easy to operate and maintain.

Automatic Swiss Type Lathe SL325 Features

Swiss lathes have become indispensable key equipment in many high-end manufacturing industries with their excellent processing capabilities and high precision.

They have promoted the development and innovation of precision manufacturing technology. Due to their high precision, high efficiency and versatility, they are widely used in many industries.

Product application industry

Swiss lathes are known for their excellent machining accuracy, high efficiency and automation level. They are particularly suitable for the production of long and small workpieces, such as electronic components, medical devices, watch parts, aerospace parts, etc.

In electronics manufacturing, they are used to produce connectors, precision screws, miniature bearings and other electronic components.

In medical devices, they manufacture implants, surgical instruments, small precision parts, etc.

In the automotive industry, they produce engine parts, precision gears, etc.

Video

Product Parameter

| Item | Unit | SL325 |

| Maximum processing bar diameter | mm | Φ32 |

| Spindle through hole diameter | mm | Φ36 |

| Spindle speed | r/min | 6000 |

| External turning tool position | ea | 6 |

| Maximum end face drilling diameter | mm | Φ13 |

| Maximum speed of radial live tool | r/min | 4800 |

| External Turning Tool Specifications | mm | 16*16 |

| Dimensions | mm | 2610×1640×1920 |

| Machine weight | Kg | ≈3700 |