PRODUCT

SL205 Automatic Swiss Type Lathe

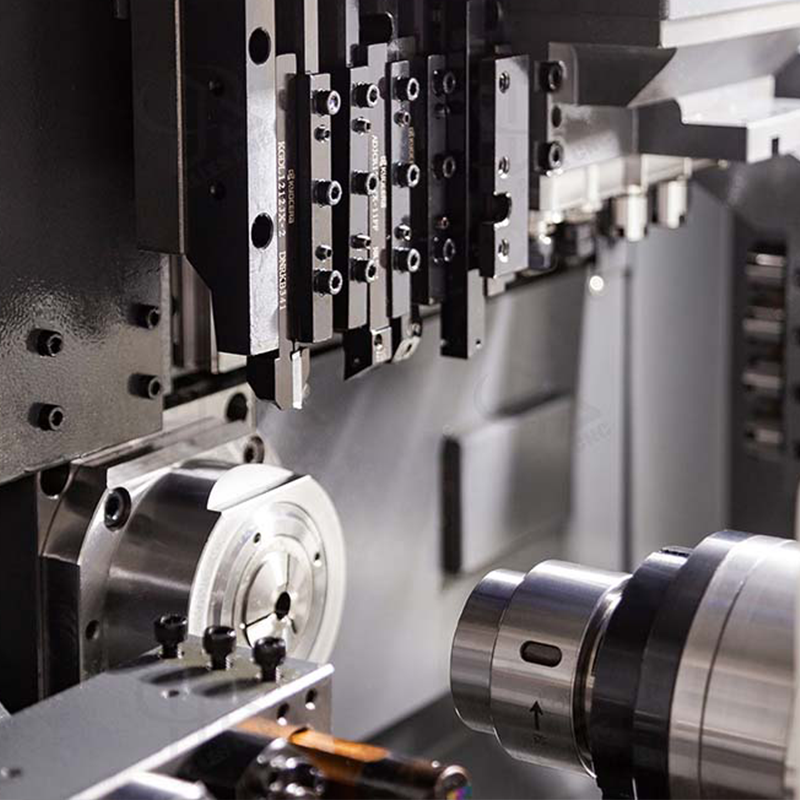

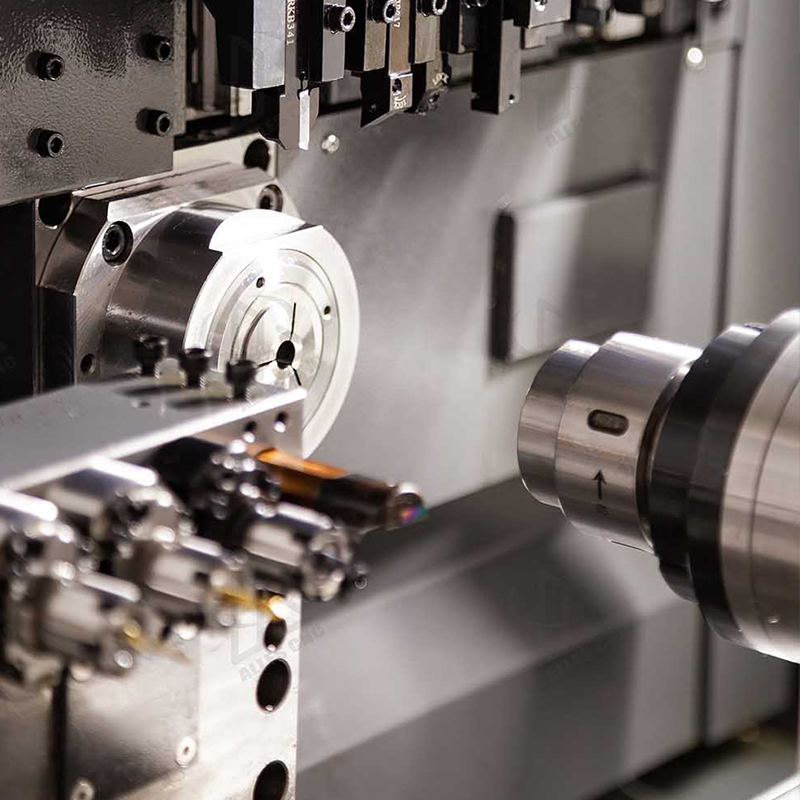

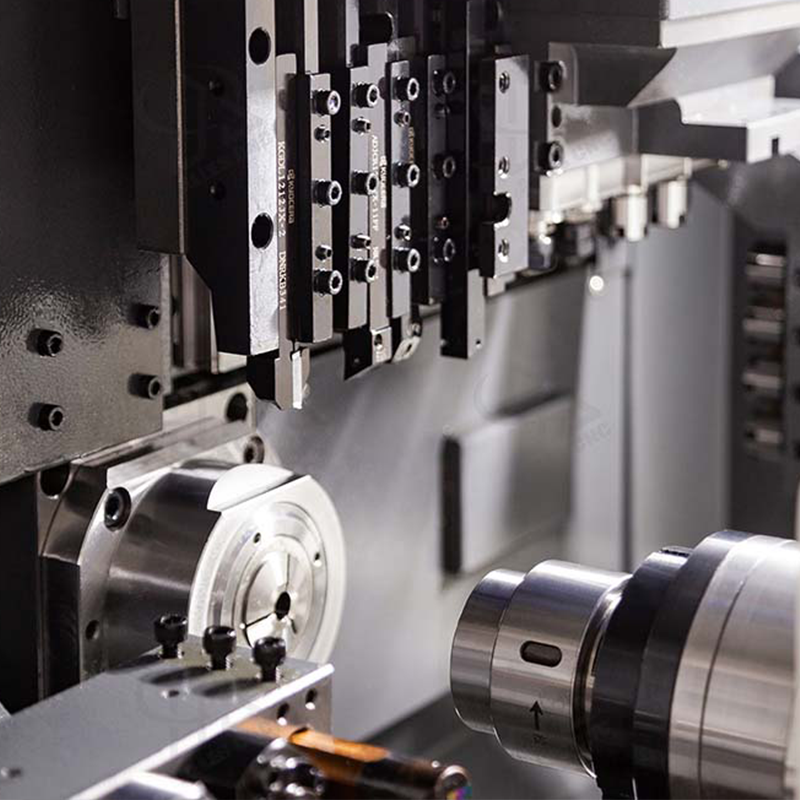

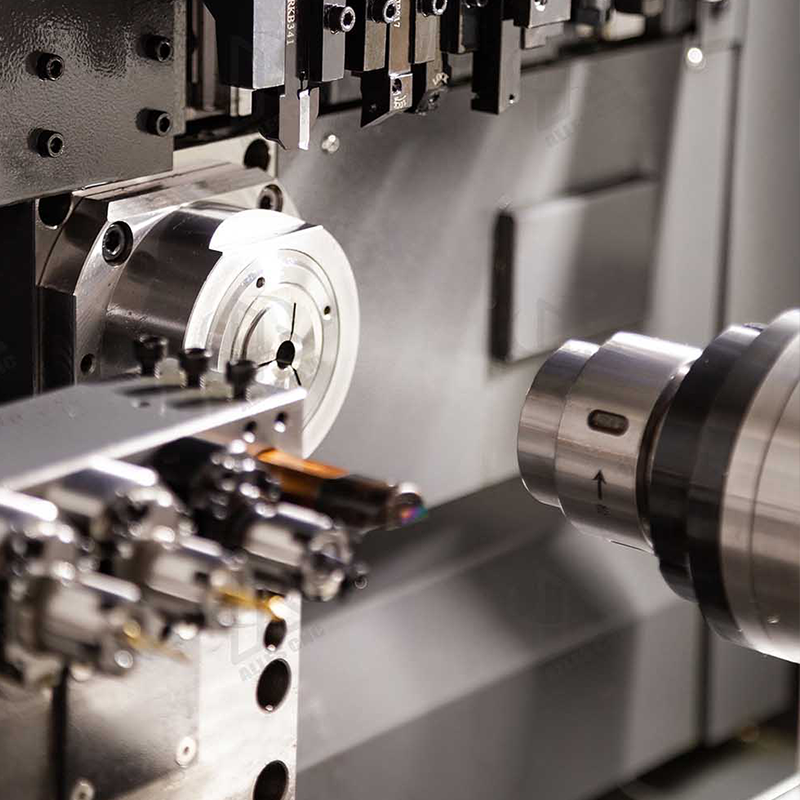

Swiss lathes are equipped with precision guide rods or sliding spindles, which can closely support the workpiece, reduce deformation and vibration of the workpiece during processing, and improve processing accuracy.

The workpiece is fixed by multiple support points during processing, especially near the cutting area, ensuring that the workpiece can remain stable under high-speed rotation, which is suitable for processing long and thin workpieces.

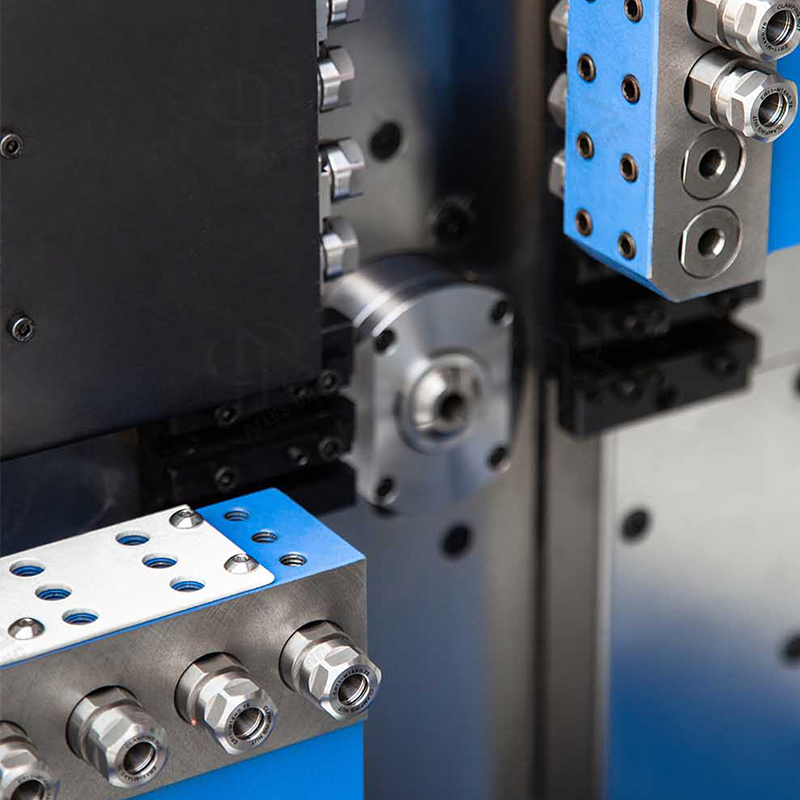

Swiss lathes use a high-rigidity structure and a precise control system, which can achieve extremely high machining accuracy and repeat positioning accuracy, meeting the requirements of micro-machining.

The overall design of the lathe is compact and occupies a small area, making it suitable for use in production environments with limited space, while being able to efficiently complete the machining of complex workpieces.

Automatic Swiss Type Lathe SL125 Features

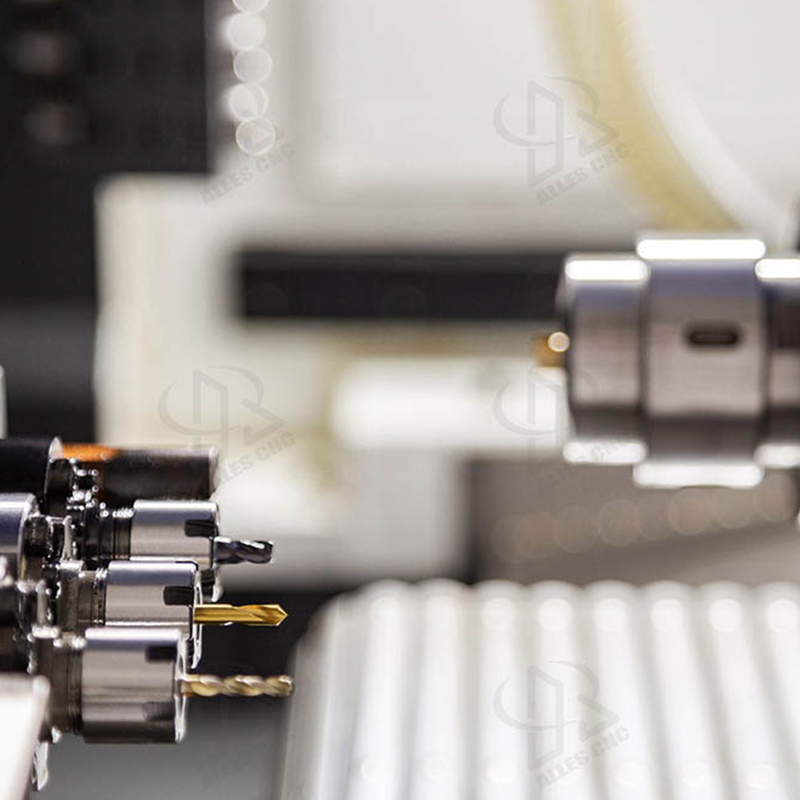

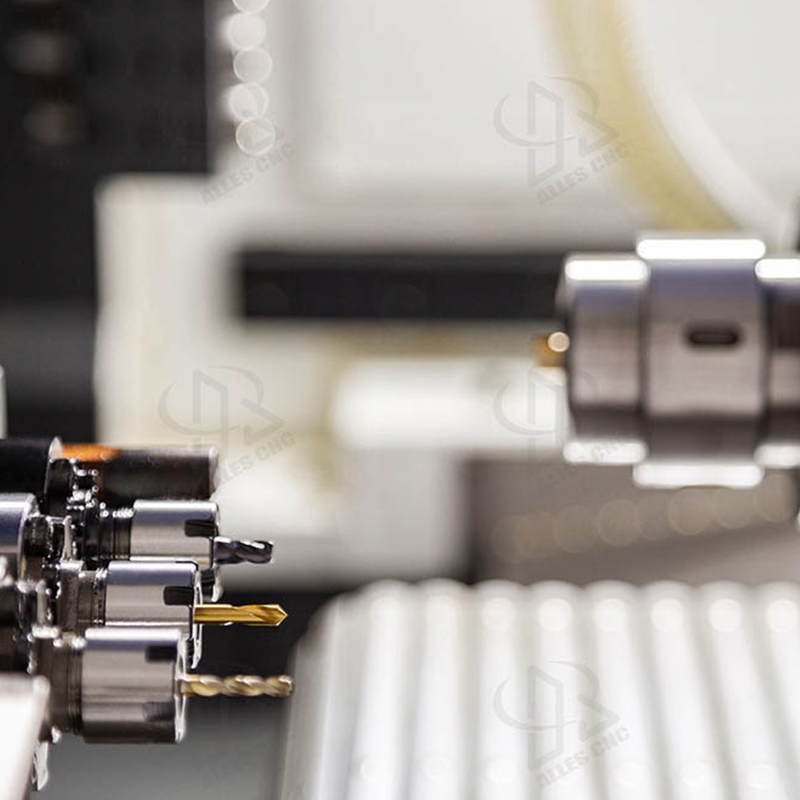

Modern Swiss lathes are usually equipped with advanced CNC systems, which support complex programming and automated operations, and improve processing flexibility and automation level.

In addition to turning, Swiss lathes can also perform milling, drilling, threading and other processing operations to meet diverse manufacturing needs.

High production efficiency: A large number of high-quality parts can be processed in a short time, which is suitable for mass production.

Product application industry

Swiss lathes produce complex watch cases, watch straps, movement parts, etc., which require extremely high dimensional accuracy and surface finish.

Precision surgical tools, such as scalpels, forceps and other surgical instruments, require high precision and high reliability.

Medical device parts: including syringes, endoscope components and other parts that require high-precision processing.

High-performance parts, such as engine parts, fuel system components and structural parts, require high strength and high precision.

Complex shape parts, suitable for processing aerospace parts with complex geometries.

Video

Product Parameter

| Item | Unit | SL205 |

| Max.Turning Diameter | mm | Φ20 |

| Spindle through hole diameter | mm | Φ25 |

| Spindle maximum speed | r/min | 8000 |

| Maximum machined workpiece length | mm | 50 |

| Maximum face drilling diameter | mm | Φ10 |

| Maximum speed of back shaft | r/min | 8000 |

| Cylindrical turning tool position | Pcs | 6 |

| Dimensions | mm | 2300×1300×1770 |

| Machine net weight | Kg | ≈2400 |