PRODUCT

Characteristics of large CNC lathes

CNC control system: Large-scale CNC lathes adopt computer numerical control systems, which can realize complex machining processes through pre-programming to improve accuracy and production efficiency.

High-precision machining: The CNC system can achieve highly precise machining, ensuring the dimensional accuracy and surface quality of the workpiece, and is suitable for processing parts with higher precision requirements.

High efficiency: CNC lathes have the advantage of a high degree of automation. They can complete a series of processing procedures continuously and automatically to improve production efficiency.

Flexibility: By changing the CNC program, workpieces of different shapes and specifications can be processed, improving the flexibility and versatility of the equipment.

Multi-axis control: Large CNC lathes usually have multi-axis control functions, which can control multiple motion axes at the same time to achieve complex three-dimensional processing.

Monitoring and diagnostic functions: The CNC system has fault monitoring and diagnostic functions, which can detect and handle equipment faults in a timely manner and improve the reliability and stability of the equipment.

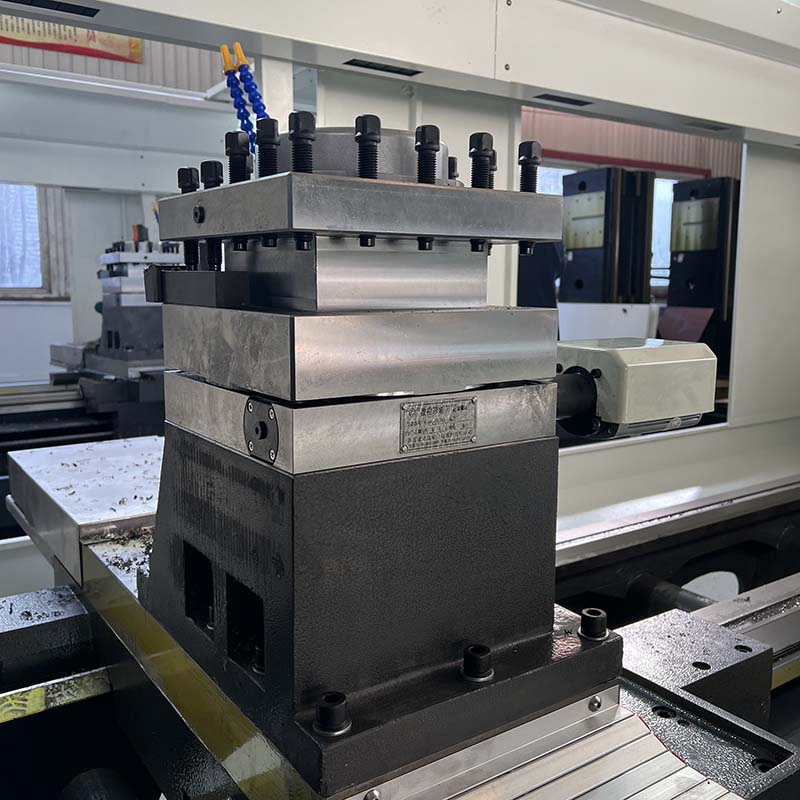

Automatic tool changing system: Equipped with an automatic tool changing system, it can automatically change different types of tools according to processing needs to improve processing efficiency.

Product application industry

Large parts processing: Suitable for processing large workpieces, such as machine tool beds, wind power equipment spindles, automobile engine blocks, etc.

Mold manufacturing: Used to manufacture large molds, such as automobile body molds, aircraft parts molds, etc.

Aerospace field: Used for processing complex parts in the aerospace field, such as engine parts, aircraft structural parts, etc.

Energy equipment manufacturing: Suitable for processing large energy equipment, such as generator set parts, nuclear power equipment parts, etc.

Rail transit field: Used for processing rail transit equipment, such as high-speed train wheels, railway vehicle parts, etc.

Video

Product Parameter

| Item | Unit | CK61100X3000 |

| Maximum turning diameter of bed | mm | Φ1000 |

| Maximum turning diameter of slide | mm | Φ630 |

| Maximum turning length | mm | 3000 |

| Maximum machining diameter | mm | Φ1000 |

| Maximum bar diameter | mm | Φ500 |

| Spindle hole diameter | mm | Φ105 |

| X/Z axis travel | mm | 500/3000 |

| Net weight | kg | 6500 |

| Machine Size(L×W×H) | mm | 5400/1900/2000 |