PRODUCT

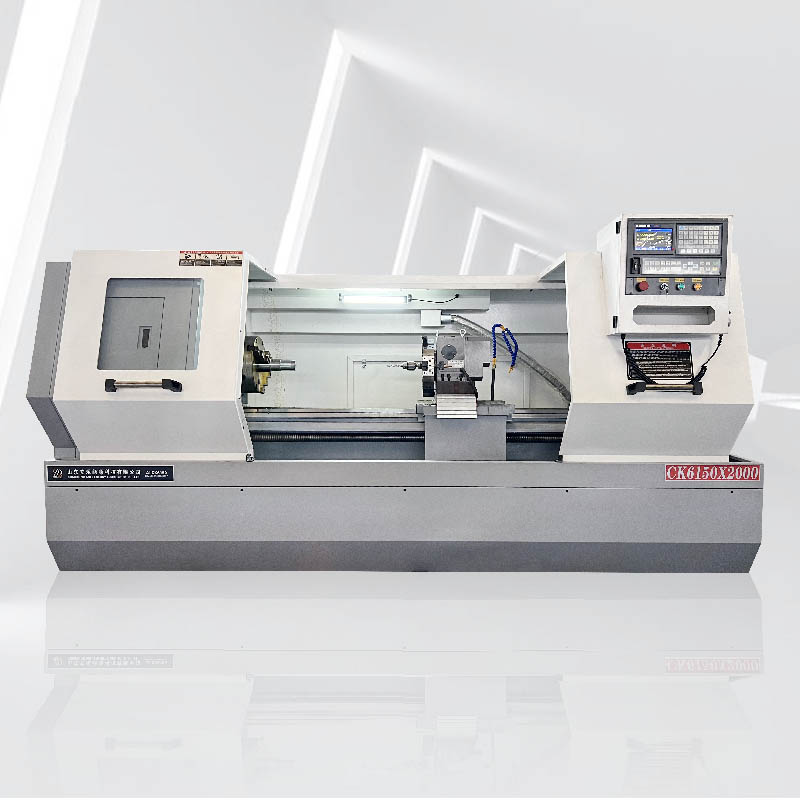

Flat Bed CNC Lathe CK6150X2000

CK6150X2000 CNC lathes are widely used in the automotive industry. They can process various complex auto parts and accessories, improve production efficiency and product quality, and have made important contributions to the development of the automotive industry.

The CK6150X1000 CNC lathe has the characteristics of inertia, versatility, automation and reliability. It is suitable for various processing needs and is an important tool in modern manufacturing.

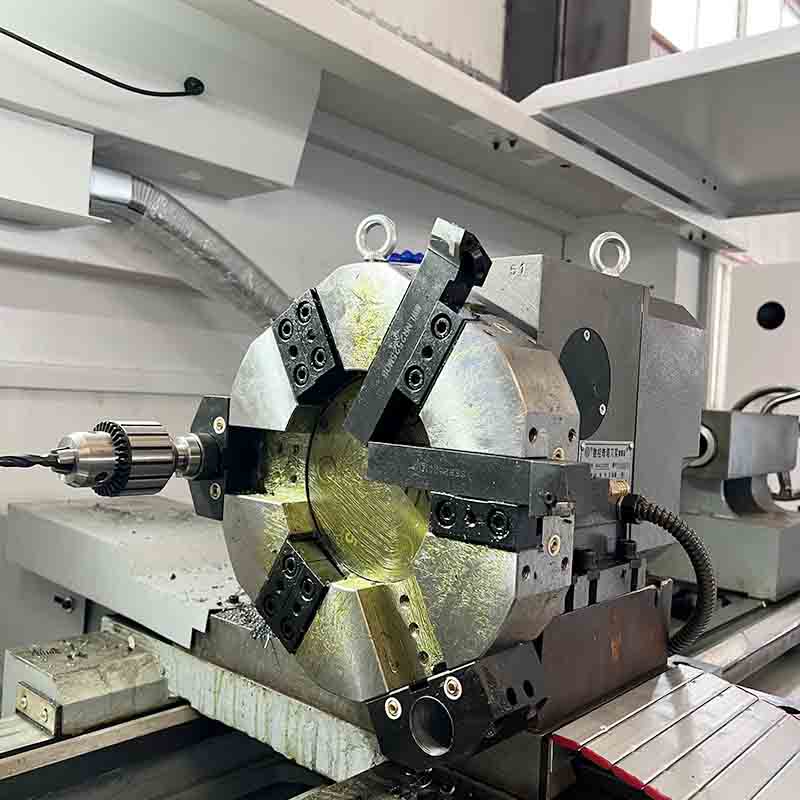

CK6150X1000 CNC lathes are usually equipped with multiple tool positions, allowing multiple processing operations to be completed on the same workpiece, such as turning, boring, tapping, etc. This increases productivity and reduces equipment replacement time.

Features of CK6150X2000 CNC lathe

Save labor costs: Due to the high degree of automation, the CK6150X2000 CNC lathe usually only requires a small number of operators to supervise and manage, which can significantly reduce labor costs.

Stability and Reliability: This type of CNC lathe is usually built with sturdy construction and high-quality materials to ensure stable operation and reliability over a long period of time.

Wide applicability: CK6150X2000 CNC lathe is suitable for processing a variety of different materials, including metals, plastics and composite materials. It can be used to produce various parts and workpieces, so it has a wide range of applications in manufacturing.

Product Application Industry

Manufacturing: CNC lathes are an important part of the manufacturing industry and are used to process various metal and non-metal materials and manufacture parts and workpieces. This includes automobile manufacturing, aerospace, shipbuilding, machinery manufacturing and other fields.

Aerospace: CNC lathes are used to manufacture various components of aircraft, spacecraft and aerospace engines, such as engine casings, turbine blades, cockpit components, etc. High precision and complex machining requirements make CNC lathes an indispensable tool.

Video

Product Parameter

| Item | Unit | CK6150X2000 |

| Max swing over bed | mm | Φ500 |

| Maximum swing over slide | mm | Φ290 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 2000 |

| X/Z axis maximum stroke | mm | 2000 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |