PRODUCT

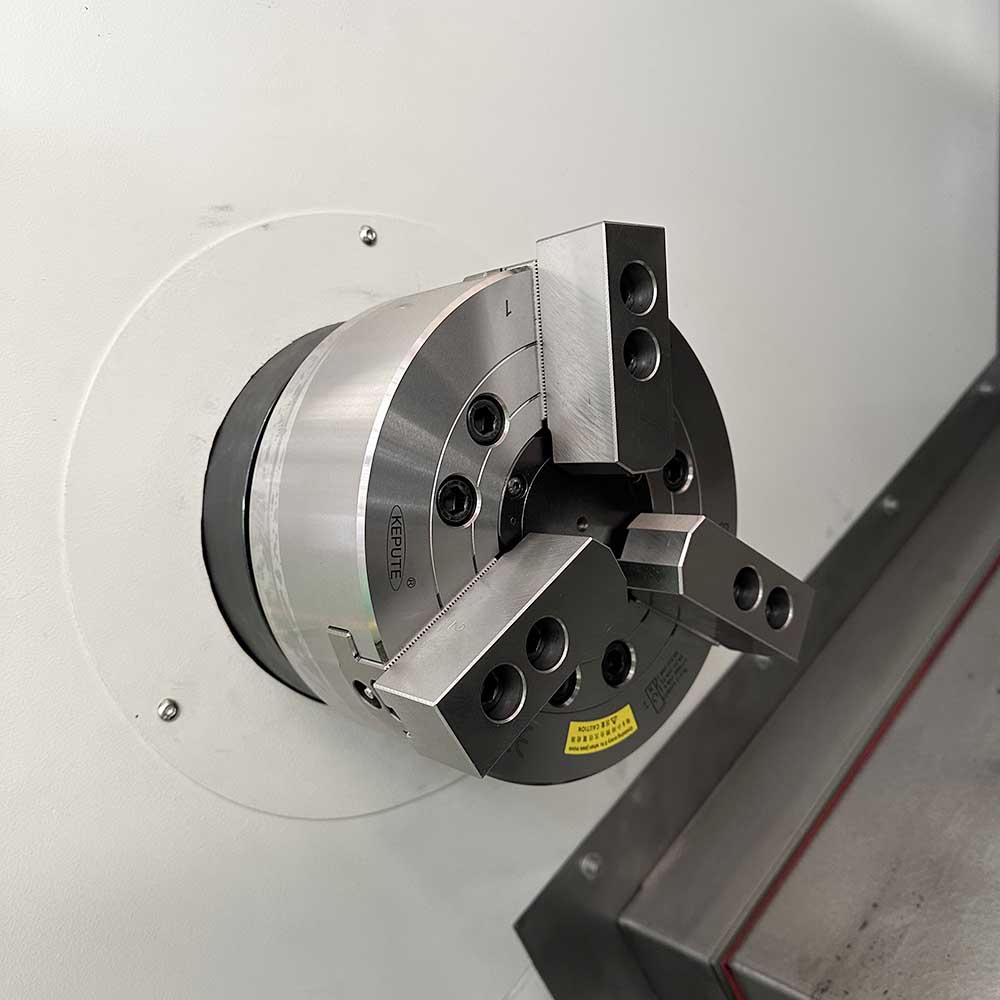

CNC Turning And Milling Compound TCK550D

The CNC Turning and milling center is characterized by its combination of turning and milling functions, making it a multi-functional machine tool. It offers advantages such as high precision, high efficiency, flexibility, and a high degree of automation. It can meet the demands for machining complex parts and enhance production efficiency while reducing costs.

CNC Turning and milling centers have the ability to perform both turning and milling functions, enabling a single machine to carry out a variety of different machining operations. This enhances production efficiency and machine utilization.

The CNC system of the Turning and milling center enables high-precision control and positioning, guaranteeing the accuracy and consistency of part machining.

Product Features:

1.The CNC Mill-turn center enables the machining of complex contoured parts, such as curves, inclined surfaces, and chamfers, by employing different axial movements during turning and milling processes.

2.The CNC Mill-turn center's CNC system allows for program adjustments and optimization according to diverse machining requirements, catering to different types and specifications of workpieces, providing increased machining flexibility and diversity.

3.The CNC Mill-turn center is equipped with high-speed cutting and rapid tool-changing capabilities, which significantly shorten the machining cycle and enhance production efficiency.

4.The CNC system of the Combined CNC lathe-mill machine enables automated operations, including automatic tool changing, measurement, and compensation, thereby minimizing human intervention and the potential for operational errors.

5.The high precision of the Combined CNC lathe-mill machine, combined with its automation capabilities, contributes to reducing scrap rates, energy consumption, and labor costs, while simultaneously improving production efficiency and economic benefits.

Product Application Industry

1.The CNC Milling-turning center can perform both turning and milling operations simultaneously, making it suitable for machining complex and high-precision components, such as turbine blades in the aerospace industry, rotors in aviation engines, and camshafts in automotive engines.

2.The CNC Milling-turning center offers multifunctionality, allowing for turning, milling, drilling, threading, and other operations. It is suitable for machining parts with multiple functionalities or special shapes, such as complex gearboxes in mechanical equipment, sliding tables in machine tools, and intricate structures in molds.

Video

Product Parameter

| Item | Unit | TCK550D |

| The maximum upper rotation diameter of the bed surface | mm | 550 |

| The maximum processing diameter on the tool post | mm | 320 |

| Maximum processing length | mm | 550/900 |

| Spindle maximum speed | rpm | 3500 |

| Spindle hole diameter | mm | Φ82 |

| bar stock diameter | mm | Φ70 |

| X-axis maximum travel | mm | 315 |

| Z-axis maximum travel | mm | 650/1000 |

| Length X width X height | mm | 2800/3300x1900x2200 |

| weight | kg | 4600/5500 |