PRODUCT

Slant Bed CNC Lathe For Metal TCK6340

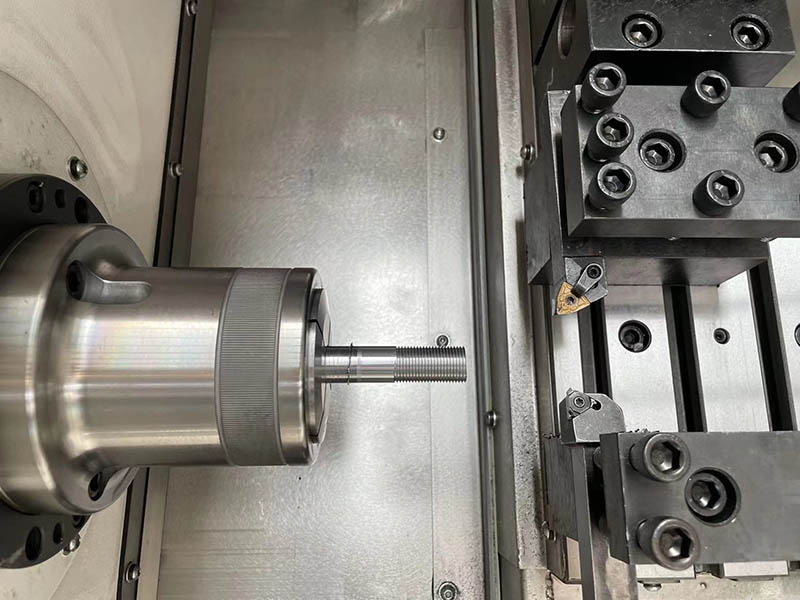

ALHAASES CNC Slant Bed CNC Lathe is suitable for processing small and medium shaft and disc parts, and can turn various threads, arcs, cones and internal and external surfaces of rotary bodies. It is widely used in plumbing equipment, valves, electrical appliances, instruments, automobiles, motorcycles Vehicles, bearings and other industries.

ALHAASES CNC Slant Bed CNC Lathe High-quality high-strength cast iron casting The overall bed has good rigidity and high precision. The surface of the guide rail is quenched by super audio frequency, with high hardness and long life. Large, high passability, stable workpiece clamping with dual chucks

This series of Slant Bed CNC Lathe adopts a slanted bed, which is suitable for processing various small and medium-sized shaft and disc workpieces. It has the characteristics of simple programming, reliable structure, convenient operation and high degree of automation.

Slant Bed CNC Lathe is suitable for turning various inner and outer cylindrical surfaces, conical surfaces, arc surfaces and other rotating surfaces, and for turning various threads. It is a high-efficiency CNC machining equipment commonly used in the machining field.

Product Features:

1. Reasonable layout, large internal space, fashionable shape design.

2. High-precision sleeve-type independent spindle structure, high-speed hydraulic rotary system,

3. Make sure the high speed of CNC slant bed lathe.

4.CNC slant bed lathe absolute value servo motor will not cause errors due to power failure.

5. Selected high-quality resin sand, integral casting of the base bed, strict aging treatment, has the best rigidity, excellent shock absorption performance and toughness, which can ensure the stability of CNC turning lathe.

6. The installation method of the central and pre-stretching screw improves the rigidity and machining accuracy of the CNC turning lathe.

Product Application Industry

This series of china inclined Bed CNC Lathe is mainly used to process the internal and external threads of pipe workpieces, and also has the function of China CNC lathe machine, which can process the outer circle, inner hole and end face of workpieces such as shafts and discs;

This series of CNC lathe machines are widely used in the processing and repair of drill pipes, joints, casings and other workpieces in the petroleum industry, and can also be used in geological exploration, mineral mining, chemical smelting, pipeline network construction, machinery manufacturing and shipbuilding industries.

Video

Product Parameter

| Item | Unit | TCK6340 |

| Max. swing dia. over bed | mm | Φ520 |

| Max. swing dia. over slide | mm | Φ220 |

| Max. processing length | mm | 410 |

| Spindle speed | rpm | 50-3000 |

| Spindle hole diameter | mm | 66 |

| Weight | KG | 3000 |

| Machine size | mm | 2500×1620×1890 |